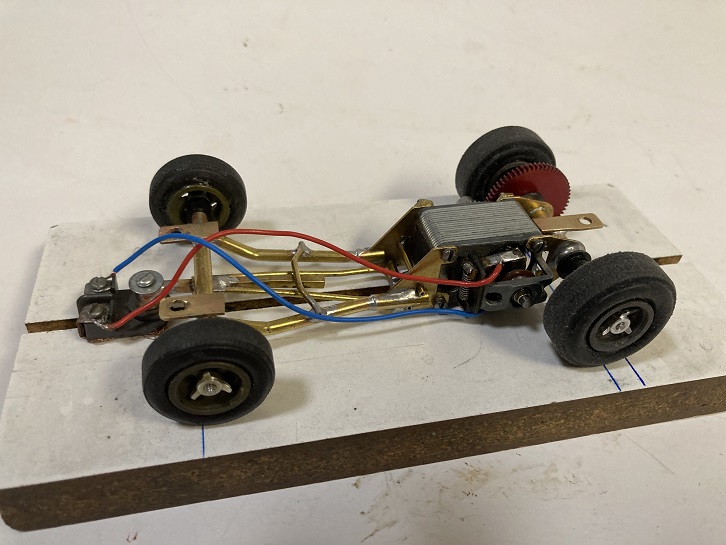

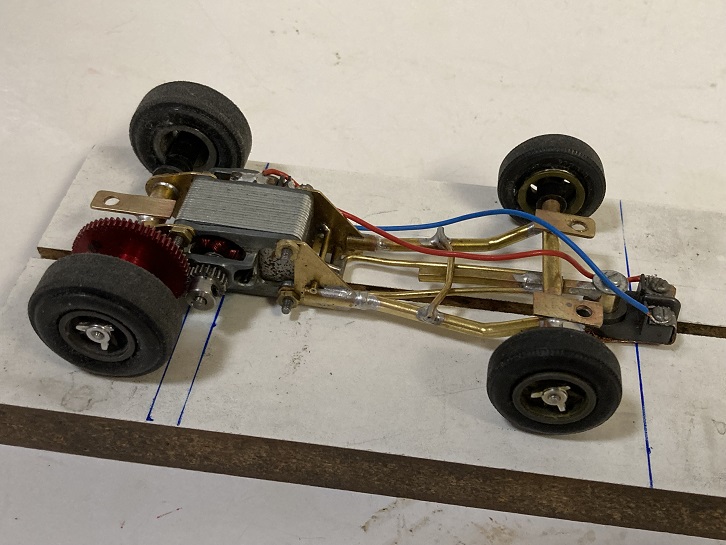

1968 Abarth 2000 Sport Spider

#1

Posted 08 April 2023 - 07:05 PM

- Jencar17, MSwiss, Tex and 4 others like this

#2

Posted 09 April 2023 - 05:40 PM

Nice, don't know where you find the time and ambition to do all these cars.

I know first hand that these " non-kit " builds take lots of time, planning and fiddling.

Oh, and skill too.

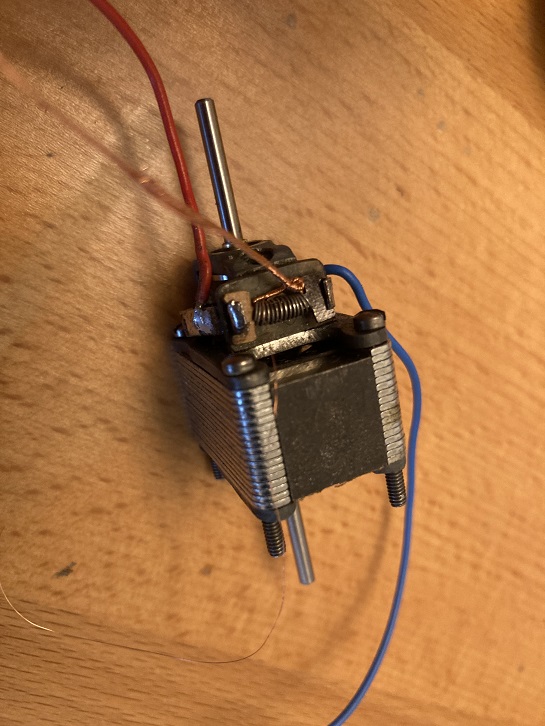

Pretty involved on your brush spring thing.

I too have not found the "secret procedure" on this.

We need to find someone who worked at Pittman 60 years ago I guess.

Anyway, the first thing you need is lots of extra parts for these old motors for the lost and broken bits when you attempt this.

Secondly, make sure no kids are present to hear the things that come out of your mouth as the parts fly off to somewhere never to be seen again ![]()

![]()

![]()

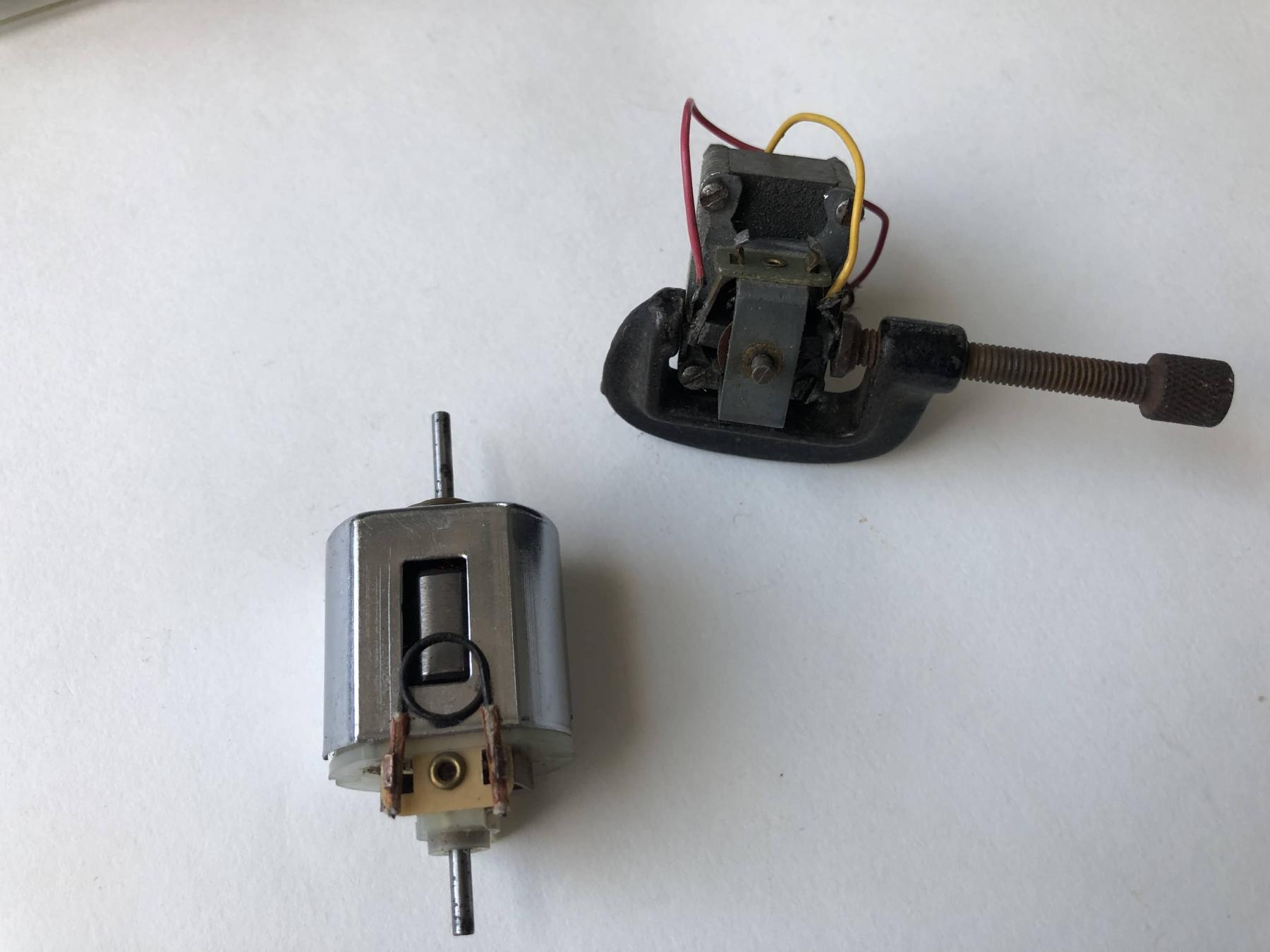

I've used a clamp to hold the brushes as shown.

Not the answer but it helps.

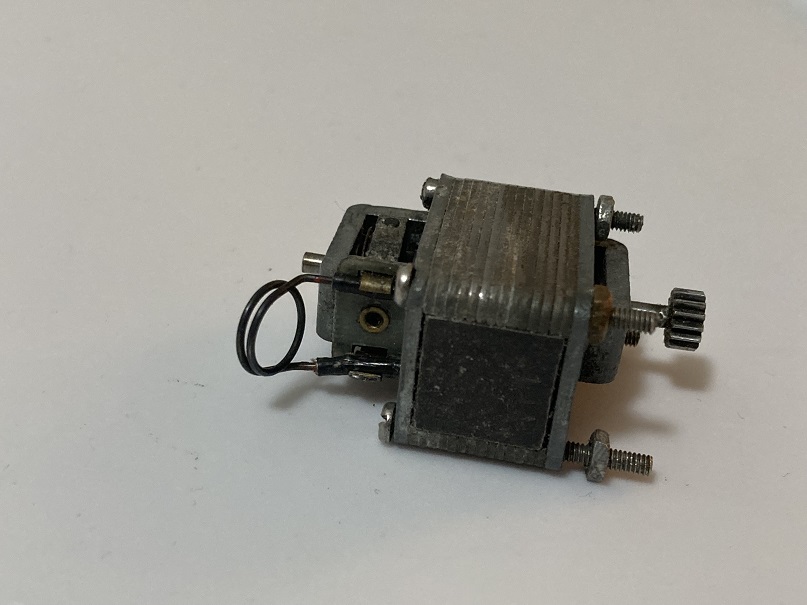

I also use the type spring as shown on this Ram-Boochie motor.

I think Rick uses these a lot.

If you can't find this type I think you have enough talent to make one out of wire and insulation.

- Slot Car Rod likes this

Joe Lupo

#3

Posted 09 April 2023 - 10:39 PM

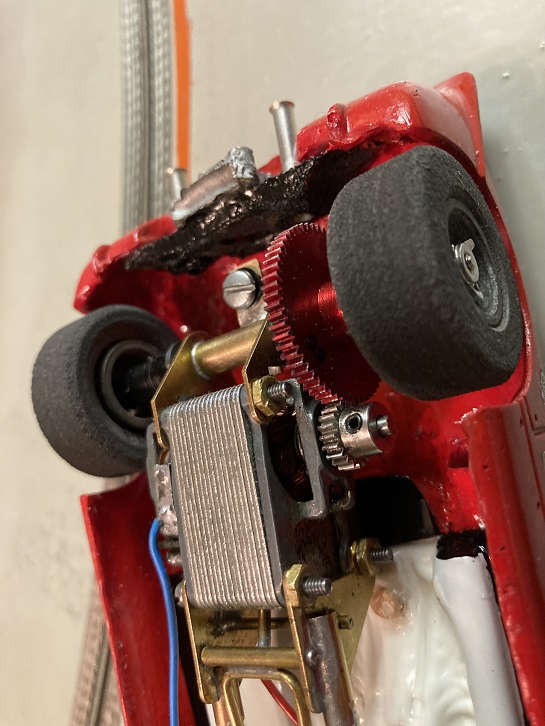

Great idea, Joe. Here is one I just tried. Fits great.

Spares are needed. The Pittman plungers break just by looking at them! The parts do fly an incredible distance.

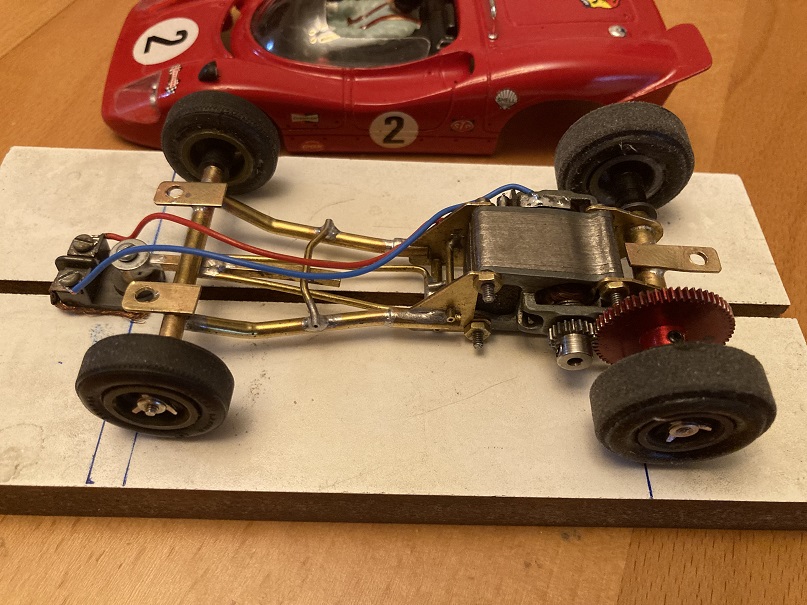

I told Rick about the mediocre handling of the car. He built a similar-sized car years ago, powered by a Pittman 65. It was a 1/32nd scale Cobra. He said the car worked great with German tires. He suggested grinding down these tires. Also, try grinding the sides if they are too wide.

Here are the German tires on the car.

They really work on the car. It handles great now. Thanks, Rick. I think the German tires have less grip than the other tires and let the car slide just the right amount in the corners.

Tire test. German tires on car. Paul's urethane tires. Gel Claw tires.

- Jencar17 likes this

#4

Posted 10 April 2023 - 08:41 AM

That's great you got the handling dialed in ![]()

- Slot Car Rod likes this

Paul Wolcott