For my Monogram Chaparral project, I was having trouble finding the needed 48 tooth spur gear and decided I wanted to try 3D printing my own just for grins. And I was able to find a really cool website (https://www.stlgears...erators/3dprint) that given some standard gear dimensions, is able to generate an STL file which I was then able to import into TinkerCAD to do my final tweaks. But my question is this and it is probably more meaningful to machinists but I know there are a fair number of you out there in SlotBlog land: Is there a standard pressure angle for a 48 pitch slot car spur gear? I played around with it a bit and using a 20 degree pressure angle seemed to yield teeth that match my reference cox spur gear but I was just curious if there was an actual standard.

3D-printed gears

#1

Posted 03 July 2023 - 07:32 PM

- NSwanberg likes this

#2

Posted 04 July 2023 - 12:29 AM

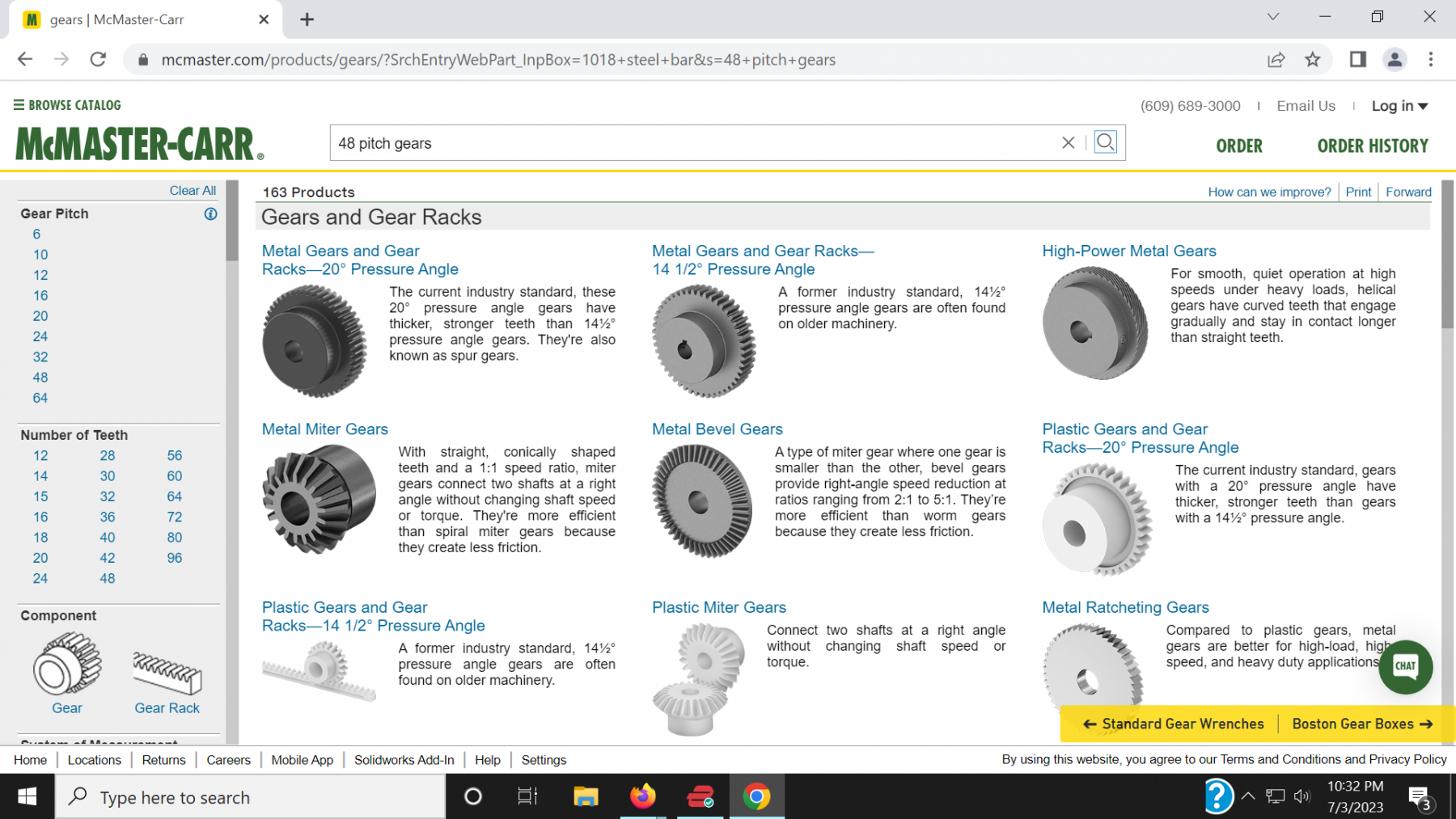

McMaster seem to indicate that 20 degree is the current standard. But if you read on it says the FORMER standard was 14 1/2 degrees.

So are we CURRENT or FORMER?

"

The current industry standard, these 20° pressure angle gears have thicker, stronger teeth than 14½° pressure angle gears. Made of plastic, they run quieter than metal gears and have good corrosion and chemical resistance. They’re also known as spur gears.

- NSwanberg likes this

#3

Posted 04 July 2023 - 09:33 AM

Cox, and the copys we see now, don't have an exact pressure angle. They fudged things to get the gears to fit the chassis and still get a good mesh. But still better than the crown gears, which don't have real gear teeth. 20 degrees would be a good place to stay as long as the difference between the diameter of the pinion and diameter of the spur doesn't become to great. I.E, 8 tooth pinion and 50 tooth spur. (not likely with 48 pitch gears.)

#4

Posted 04 July 2023 - 10:16 AM

Thanks guys ... you've both confirmed that my using 20 degrees is probably about right. Martin, I tried using 15 degrees and the teeth were definitely too skinny. I also tried 25 degrees but they looked overly thick. So I've ordered a couple of 20 degree gears to be printed thru Shapeways using nylon impregnated plastic (same stuff used for drone rotors so its a pretty tough material).

#5

Posted 04 July 2023 - 10:42 AM

That sounds like a good move Larry. How do yo plan to lock the gear to the axle?

#7

Posted 04 July 2023 - 11:15 AM

Oh yes I remember that. Nice and narrow, strong too ![]()

Does it get just 2 screws to pull it to the wheel?

#8

Posted 04 July 2023 - 11:26 AM

It gets 5 very tiny lug bolts. Also the center hole is the exact same 8.3mm diameter as the hub's flange to center it perfectly on the hub. I'll post some picks once I have the gears in hand.

#9

Posted 04 July 2023 - 04:00 PM

Oh yea 5 holes, 2 would not balance, silly me. ![]()