JK Indy Car tech tips

#1

Posted 09 July 2023 - 12:37 PM

#2

Posted 09 July 2023 - 01:34 PM

I haven't seen much about them on here, but we race them locally, too. They're fun cars, easy to drive, and relatively easy for a beginner to get into.

What sort of info are you looking for? Are you running them box stock, or allowing some modifications?

#3

Posted 09 July 2023 - 03:16 PM

We run them in a summer series at Trains and Lanes. Hawk 7 / 11-37 gears / .750 min rear tires / independent fronts allowed, otherwise box stock. This year everyone had to choose one of the available decorated bodies.

#4

Posted 09 July 2023 - 04:47 PM

#5

Posted 10 July 2023 - 06:52 AM

I have been thinking of trying one of these cars as a new car for my home track.

What motor and rear tires come with them? And how do you like the performance of them?

#6

Posted 10 July 2023 - 07:15 AM

#7

Posted 10 July 2023 - 10:10 AM

IMO the closer the rules are to box stock the better.

When Atlanta started running the class the Hawk 7 motors were very inconsistent or worse, so many groups pick another motor to run.

Get the chassis flat, adjust the guide depth spacing and try a strip of tape across the chassis to control pan movement, and a bit of shim under the bite bar. They run and handle well.

- Tim Neja and John Luongo like this

#8

Posted 10 July 2023 - 11:05 AM

Attempt to straighten the pan so it doesnt rock back and forth on the center section. Get frustrated, walk away and have a beer. Try again, drink another beer. Curse under your breadth before determining good enough and putting it back together.

- Tim Neja, Mike Wilson and Hot Slots like this

#9

Posted 10 July 2023 - 04:40 PM

We don't race them box stock, nobody wanted to deal with the inconsistencies of the Hawk 7 and Hawk Retro motors any more. Some of my suggestions have already been mentioned, but-

Get the center section and pan flat and straight, though I generally turn the front corners of the pan up a little to minimize dragging on the track. The pan will probably be a fair amount of work. I'm in the middle of building a few of these cars for my local raceway, and I've spent at least 2-3 times as much time straightening the pans as the center sections. Also make sure that the pan does not hang below the center section. As has already been mentioned, shim under the bite bar to raise it up, if you need to. Self-adhesive body armor works well for that. They generally handle the best on our local King with the pan taped, but try it both ways. Also make sure that the guide tongue is angled up slightly. That's easiest to check with the car assembled, on a tech block like this- https://e-slotcar.co...reen-lb-1003fg/

Make sure the axle is level. If your rules allow, adjustable oilites are the easiest method, but you can also grind the edge of the hole slightly, if stock oilites are required. I don't believe we're allowed to solder the front oilites locally, so I can't comment on that. I would recommend Independent front wheels if it's allowed, as well as truing the front tires.

I use a rear axle with flats, as extra insurance against the wheels or spur gear coming loose, as well as an angled pinion, though both of those are more for reliability than performance, and if you're running them box stock, likely neither will be allowed.

One thing to keep in mind is that these cars will handle the best when run as low as possible. I run mine low enough that it's not uncommon for it to have just a touch of track gunk on the corners of the center section behind the guide, and on the front corners of the pan. You don't want it to be significantly dragging, but just a touch when cornering is ok.

I also reinforce the front of the body, especially across the front wing. If the wings get damaged and turned up, they can catch air and launch the car, especially at top speed. I run a piece of 1/2" strapping tape across the underside of the front wing, with a little tension on it to help keep the ends of the wing from getting pulled up. If you put it as far forward as possible, it doesn't interfere with the guide.

I run my lead wires through the factory retainer, in a little hump behind the guide, so they go up inside the nose, but don't actually push up on it. I also solder an earring back about halfway back on the right side of the center section to keep the lead wires on top of the chassis. If your rules don't allow that, you can get creative with some strapping tape. I put the retainer just far enough forward that I can get the pan off without unsoldering the lead wires from the motor.

Hopefully that's helpful. I can post pictures of my car, if that would help, too.

- Tim Neja, Bobby Kubik and Hot Slots like this

#10

Posted 10 July 2023 - 06:27 PM

We run ours stock. Solder in rear axle bushings. Locked front wheels. WHat everyone said about about being flat but that is every slot car. Class went over well. Also drives different than our other class. Because we run stock gear a little taller tire helps. We run 12.2V so motors were not a big issue and they were all very similar.

#11

Posted 10 July 2023 - 07:32 PM

#12

Posted 11 July 2023 - 12:13 AM

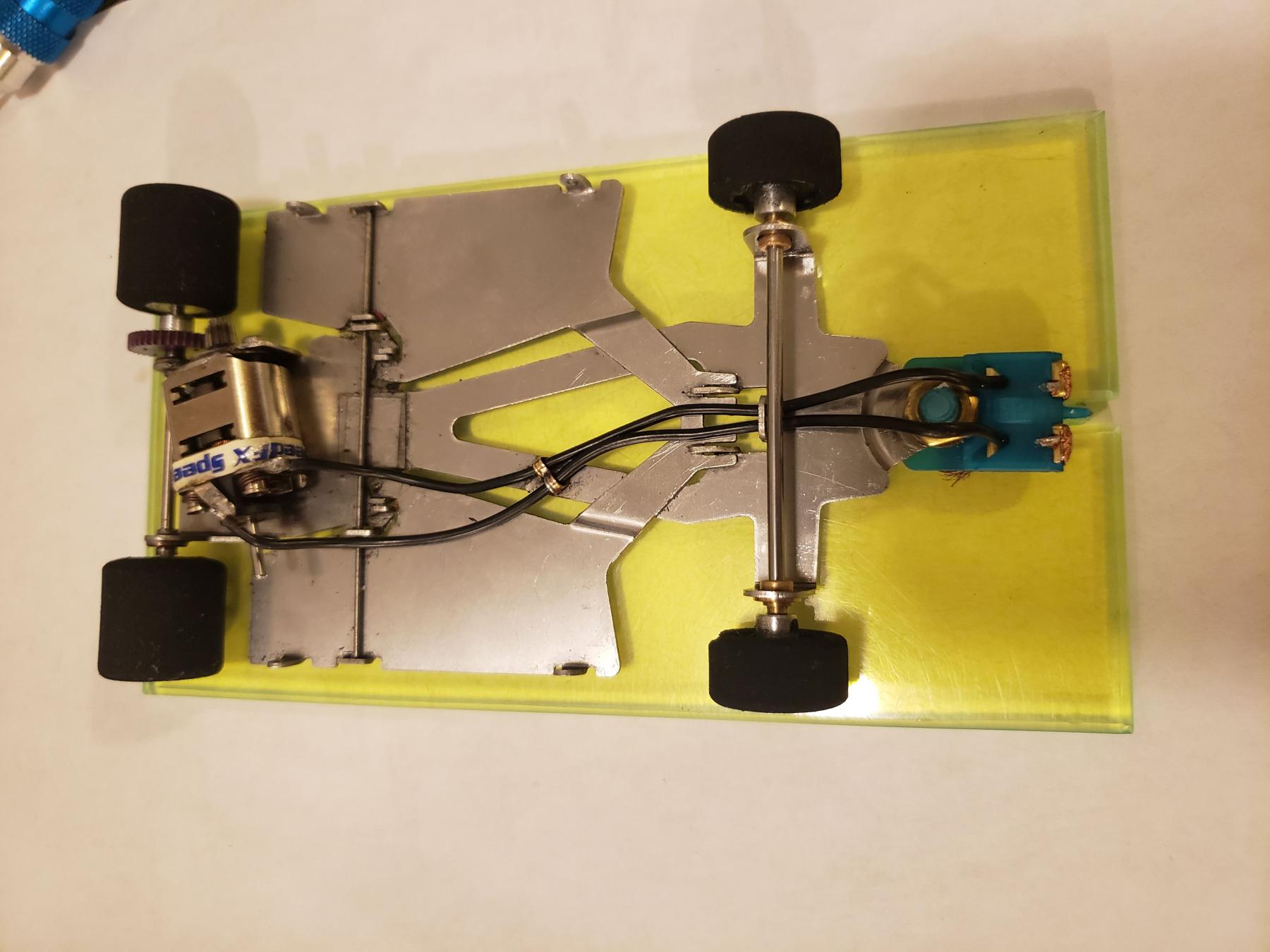

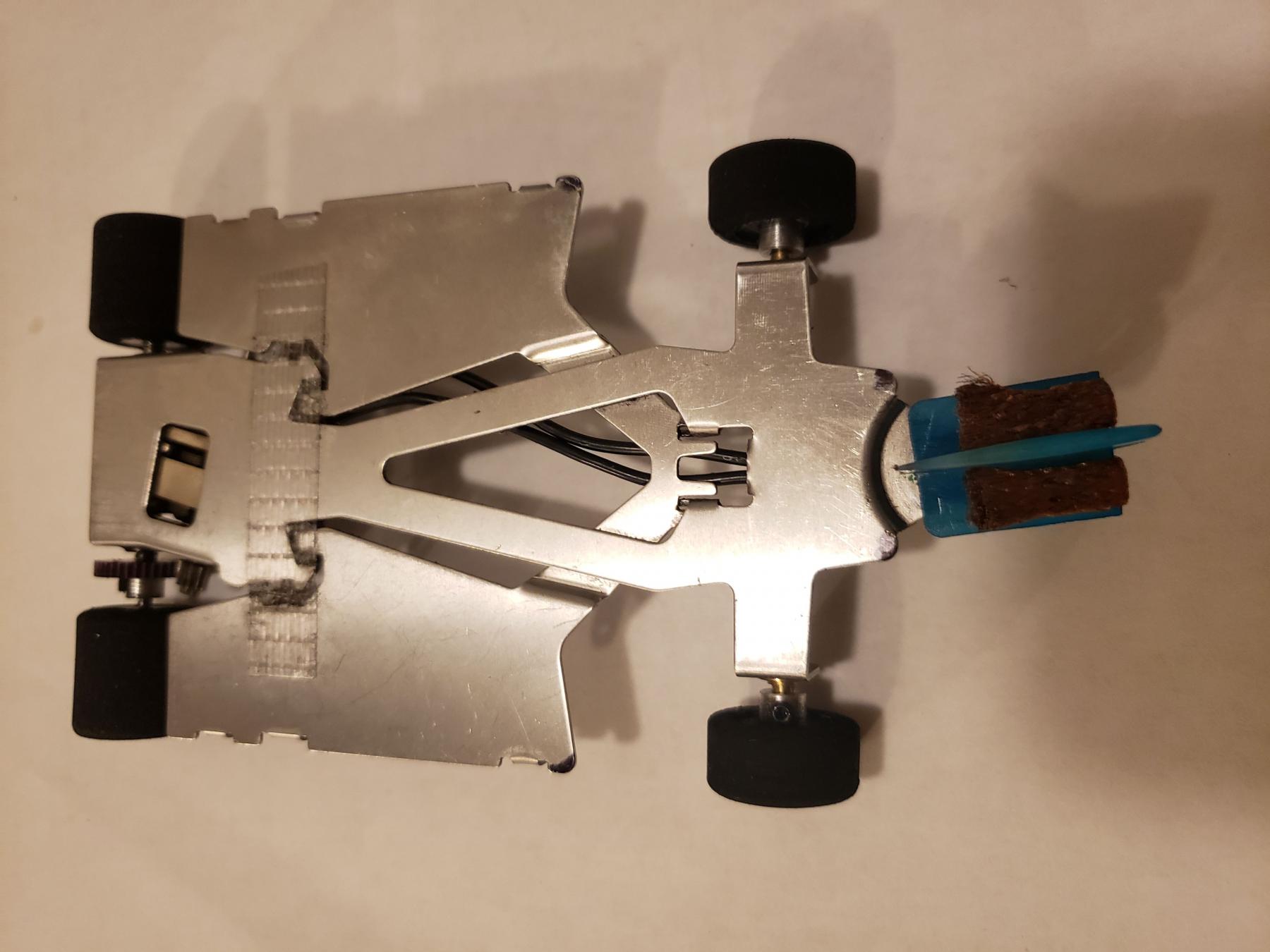

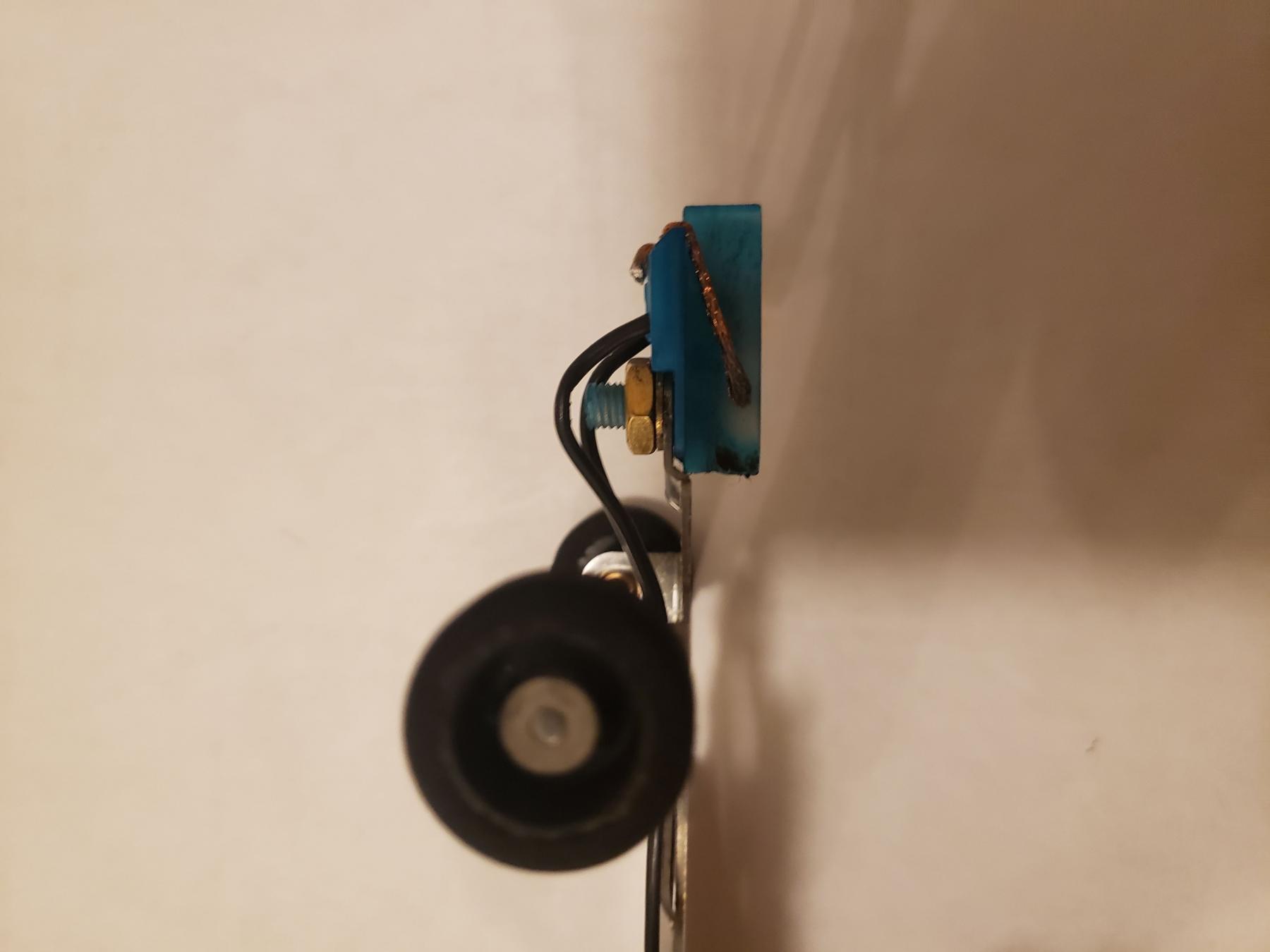

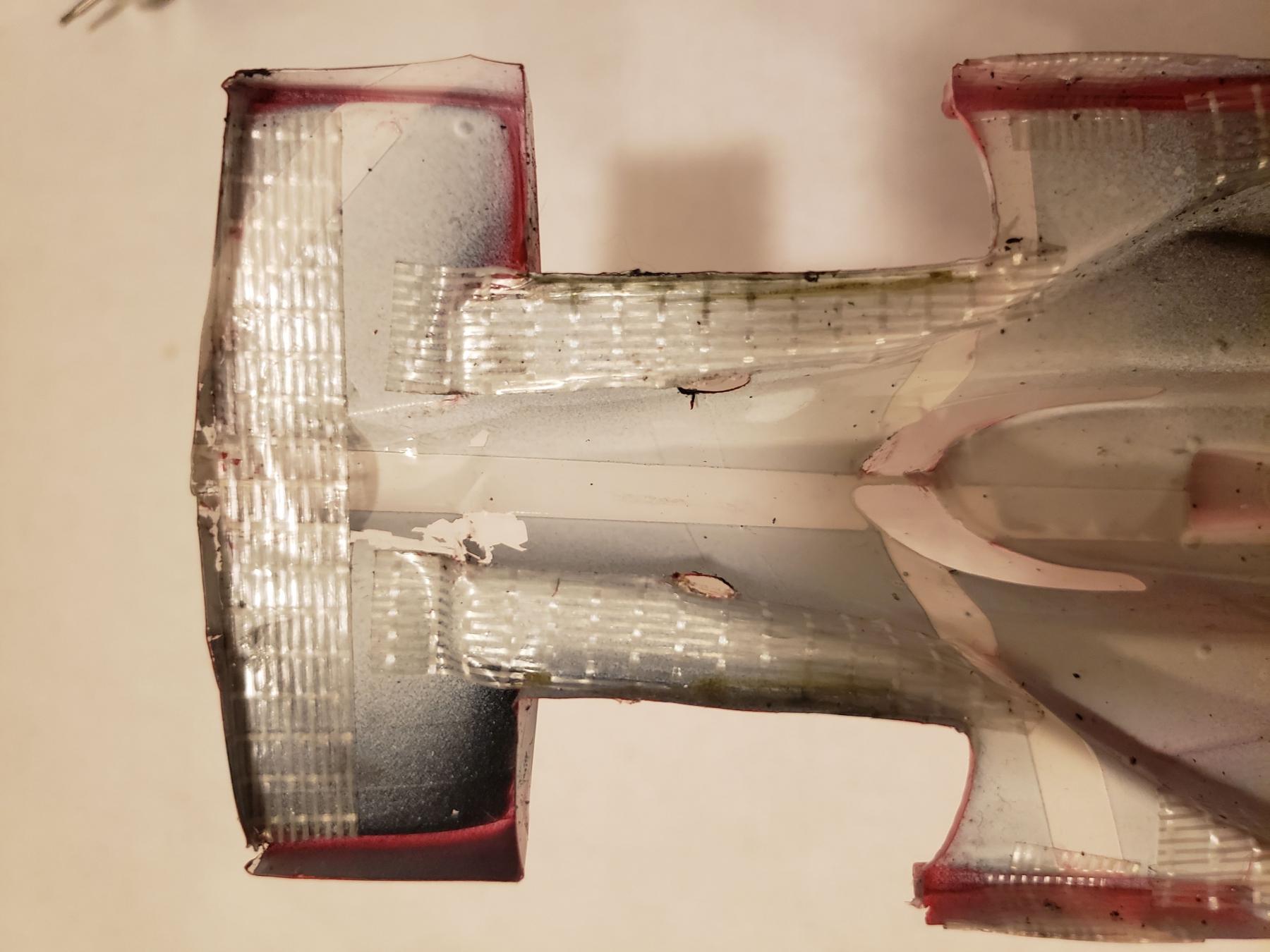

Here you go Mark. The pictures should mostly be self-explanatory, but I have notes on several.

For the picture of the bottom of the chassis, I used a Sharpie to highlight the corners of the chassis that can touch a little in the corners. Again, you don't want it dragging at least much more than what I marked.

Hopefully the third picture is clear enough to show the slight upward tilt on the front corners of the pan. it appears like it's up in the back, too, but that's just because the piece of tape on the underside of the chassis doesn't let it sot down flat on the tech block.

The fourth picture shows the upward tilt of the guide. It's easy to see on a thin block like this, because the guide is visible on the bottom side of the block, and the block gives you a nice straightedge to gauge the angle of the guide. It doesn't necessarily need to have quite as much upward tilt as this one. The biggest thing is that it's not turned down. This is sitting on the block with the rear wheels on, so it should be sitting on the block pretty much as it sits on the track

You can see the little hump of the lead wires in the fifth picture. I also use a full-sized nut and a brass washer on the guide, for just a little extra weight on the front. I don't know how much difference it actually makes, but I figure that it can't hurt. I've held the local track record several times with this car, set up this way, so it at least doesn't seem to be slowing me down.

There are also pictures of the axle collar I use for the independent front wheel rotation, and my reinforcement on the nose of the body. This particular body is the new Ralph Thorne Indy body, which our rules allow, but I do the same on the JK body.

Feel free to ask questions if you have any. I don't consider myself an expert, but I'll gladly help a fellow racer if I can. I've been given lots of help in the last two and a half years, since my two sons and I started racing, so I'll pass it on if I can. Good luck!

Another thing that's cool about these cars is that a lot of retro Can Am and Coupe bodies will fit on them, so you can run a retro-themed race by just switching bodies.

- Tim Neja and John Luongo like this

#13

Posted 11 July 2023 - 04:47 PM

the setup. In fact, we just began our latest weekly series we call CanAm Flexi.

Uses the wide variant of the JK Indy frame with any IRRA CanAm body incl optional 1/2 rear spoiler. Spec Retro Eagle motor with spec 13/37 gearing across all our tracks. With the required front tires, they look pretty realistic. Provides for a lot of good, clean racing.

- Eddie Fleming, John Luongo and Hot Slots like this

#14

Posted 11 July 2023 - 06:36 PM

#15

Posted 11 July 2023 - 09:10 PM

- Rob Voska likes this

#16

Posted 12 July 2023 - 02:08 PM

I have been thinking of trying one of these cars as a new car for my home track.

What motor and rear tires come with them? And how do you like the performance of them?

I would advise against the JK Indy cars for home (plastic sectional) tracks.

Have you looked into the 1/32 NSR open wheel cars?

Several liveries available and The Raceway Cleveland is an NSR dealer for RTRs, parts, etc.

- Tim Neja and NSwanberg like this

#18

Posted 13 July 2023 - 12:43 AM

I feel you'd have to (at the minimum) replace rear tires, motor, gearing and guide and put in a lot of time tuning to get it to run respectably on plastic sectional track.

Why not use cars designed for the correct track system?

#20

Posted 16 July 2023 - 11:37 AM

- rmjlmartin likes this