NSR slot car brushless motor

#1

Posted 23 December 2023 - 05:54 AM

- Sloter likes this

#2

Posted 23 December 2023 - 09:45 AM

Yeah, they put that up at the same time they posted their "price."

Modified brushless drone motor... check.

Anything done in limited quantity can have a high price... check.

Sales statistics have not yet been posted... check.

Comparing the NSR motor to a cobalt strap is like comparing a GTO to a Bugatti Veyron.

Price is determined by the seller, not the buyer.

Value is determined by the buyer, not the seller.

- team burrito and Tim Neja like this

Jim Honeycutt

"I don't think I'm ever more 'aware' than I am right after I hit my thumb with a hammer." - Jack Handey [Deep Thoughts]

#3

Posted 24 December 2023 - 12:30 AM

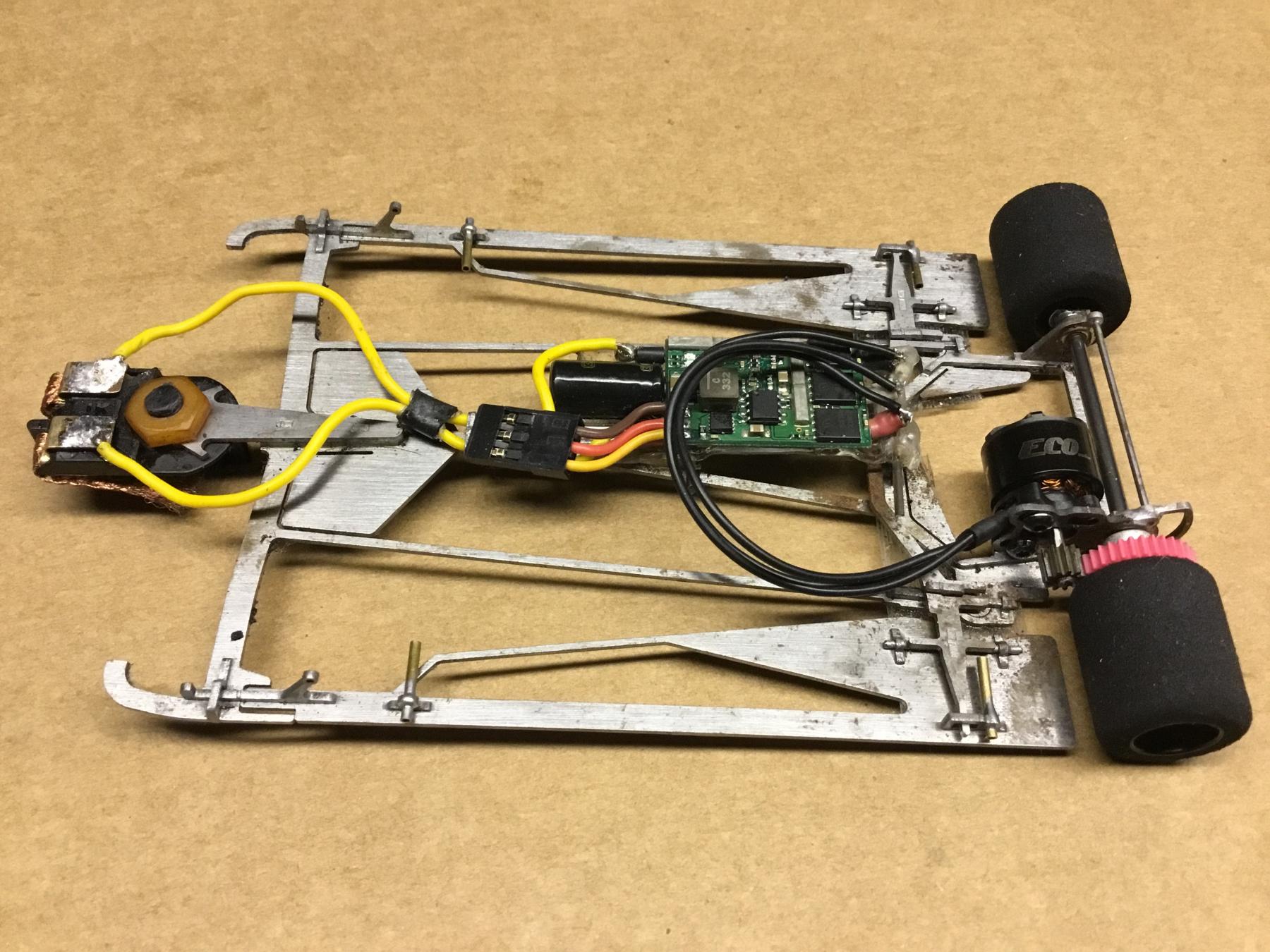

- Tim Neja likes this

First Place Loser in the JK Products

International D3 Builders Competition

#4

Posted 24 December 2023 - 01:44 AM

- team burrito likes this

#5

Posted 24 December 2023 - 09:43 AM

I'll wait for KC Racing to come out with a high performance version of their $20 motor. Some of the very useful features highlighted in the NSR may come to the lower price motors if there is any interest. Maybe a $100 blueprinted motor?

But these high end NSR motors are strictly intended for the high end ''Open Motor'' classes. Not the level of racing where $20 ''BIC motors'' are the norm now. But if I was racing Open Wing or any of the ES classes that allow brushless, the $320 US cost wouldn't seem unreasonable at all.

DISCLAIMER...This comment is completely unqualified. Ignore if it bothers you.

- Half Fast and Sloter like this

"If you have integrity, nothing else matters, and if you do not have integrity, nothing else matters."

Robert Mueller, special counsel (2013)

"... because people have got to know whether or not their president is a crook."

Richard M .Nixon, Nov 17, 1973

"Fool me once, same on... shame on you. Fool me... you can't get fooled again."

George W. Bush

#6

Posted 13 January 2024 - 10:35 PM

Sometimes you just Have to Laugh ![]()

Found this Wonderful 'Nugget' of PR on the NSR Site, proclaiming the 'Virtues' of their Horrendously EXPENSIVE brushless motor.

Fixed to the chassis by soldering it, without the risk of loosing screws.

#7

Posted 14 January 2024 - 11:45 AM

I don't know how you are going to get away from screws/ bolts.

When people started doing this, I marveled at the Richard Mack cars in the fact that they apparently weren't eating spur gears, despite the motor not being triangulated.

Apparently once you get into Budrys-Castriacone speeds, you do indeed need the motor triangulated.

This seems like the only practical solution.

Maybe have the endbell (edit-actually called the base or the stator tube) plated to be able to also tack solder it on to that triangulation thingamabob.

More text to follow, later.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#8

Posted 14 January 2024 - 02:55 PM

How sensitive are the field windings to heat in these motors? Soldering might damage them.

#9

Posted 14 January 2024 - 03:11 PM

triangulation thingamabob

Must be one of them engineering terms I reckon. ![]()

- MSwiss and team burrito like this

#10

Posted 14 January 2024 - 03:16 PM

The rotor and stator are made out aluminum, the motor must be bolted to a proper motor plate made of steel so it can be soldered to the chassis.

The motor brackets/plates are available to do this. Or like the new chassis KC is bringing out the bracket is part of the chassis to bolt the motor too.

#11

Posted 14 January 2024 - 07:06 PM

I marveled at the Richard Mack cars in the fact that they apparently weren't eating spur gears, despite the motor not being triangulated.

Apparently once you get into Budrys-Castriacone speeds, you do indeed need the motor triangulated.

Well I'm Not sure whether that IS actually even a Problem.

IF it is, people are Sure keeping it Damn Quiet !!

As We have All 'Marvelled' at Previously, there really is such little Mass !! I mean honestly, look at something like the GEPRC 1204 Series motors.

Not only are they Short, it Only weighs 3.8 grams !!! If it is 'Bolted-Up' to the Mounting bracket solidly, there isn't much that Wants to 'Pendulum' about the Bracket, especially if it is nice and Solid !!

It has NOT proven to be a problem here, ... so far.

Even the 'Wing Car' guys Aren't chewing gears.

I appreciate the Fear and theoretical Issue, but it's a bit like this whole added 3rd bearing 'caper' !!?? AND both like the NSR bracket and that other 'clown' putting the Whole motor into an old 'Open Strap Can' setup ??

It Might be fine, ... until it takes a big shunt, Open cans do Bend, as could the NSR bracket, then Axially, those 3rd bearings, are Now a mis-aligned 'Hindrance' !!

Makes me think of way back in the Old days. Some (even very famous people), would go to Stupid lengths Wire Wrapping Axles Tubes and other 'bits & bobs' to Frames etc

In my experience, if it has been built and soldered well (in the first place), ... Any accident Big enough to dis-lodge the front axle is gonna' be a biggie and I would rather it Broke-away cleanly, (allowing a much easier repair), than to have all that Wire wrapping transferring more energy to the rest of the chassis. Let alone the complete Pain in the proverbial to 'Fix' !!

I also can't help think there is some fascinated 'hang-over' regarding rpm, and gear ratios from all those years running Cobalt motors.

By design, Outrunner style motors, have Bags of Torque and do not display operational tendencies (as our beloved Strap cans did) like Dentist Drills !!!

I mean, really, is 5:40 Plus actually needed or desirable ?? ... Does it Need to Rev it's Proverbials Off ?? ... They and most current ESC's can get Very Hot doing that, whereas using less extreme ratios and making use of the inherent torque, seems to allow things to run cooler (and from recent equivalency testing), also be easier to drive !!

Makes you wonder !! ![]() ... Early days,.. guess we shall see, as things develop.

... Early days,.. guess we shall see, as things develop.

![]()

- Alchemist and Bags like this

#12

Posted 14 January 2024 - 07:12 PM

The rotor and stator are made out aluminum

Hey Tom, the 'Stator' isn't made out of Aluminium !!! ![]() , wouldn't be much 'Flux Flow' if it was,.. LOL

, wouldn't be much 'Flux Flow' if it was,.. LOL

- Tim Neja and Bags like this

#13

Posted 14 January 2024 - 07:48 PM

- Bags likes this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#14

Posted 14 January 2024 - 08:14 PM

Yes, correct ![]() it could (in effect) be made of almost anything, as long as it was strong and light enough.

it could (in effect) be made of almost anything, as long as it was strong and light enough.

- MSwiss and Bags like this

#15

Posted 14 January 2024 - 08:28 PM

This person refers to the part attached to the stator as the the base.

Also, what we usually call the rotor, he and the previous guy call it the bell.

https://youtu.be/OCA...XHggqM_9JXMvtDT

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#16

Posted 14 January 2024 - 09:53 PM

I stand corrected on the terminology I used.

The base that the screws/bolts go into is made of aluminum on these small motors. Stators can be made from a lot of different materials. I have seen 3d printed stator motors too.

The larger the motors get, different materials can be used, they develop a lot of torque to fly bigger aircraft.

Stoo you are right in your findings too. Why fix something that isn’t broken?

Martin has thousands of laps on wings and flexi type cars with bolted in motors without problems.

Getting the bracket in the right place makes the difference, just like in all types of slot cars.

Thank you for your input guys.

#17

Posted 14 January 2024 - 10:49 PM

This person refers to the part attached to the stator as the the base.

Also, what we usually call the rotor, he and the previous guy call it the bell

Yeah, I guess the Popular 'Terminology will eventually Sort itself out.

Although, that said, I have tried to be careful when discussing the Rotor ,.. 'End', as especially in England, the 'term' "Bell End", is a rather derogatory (Male genital reference) ![]()

![]()

![]()

There is also some confusion / variance in the descriptions used by (Mainly Europeans from what I have seen) regarding Magnets and Poles etc, often being referred to as Poles and Teeth ???

#18

Posted 15 January 2024 - 07:09 AM

“When people started doing this, I marveled at the Richard Mack cars in the fact that they apparently weren't eating spur gears, despite the motor not being triangulated.”

Yes Mike they are nice chassis that dont eat gears, I’ve since changed out the Talon on this one.

It handles a flat very nicely.

- Alchemist and Samiam like this

#19

Posted 15 January 2024 - 10:42 AM

Well I'm Not sure whether that IS actually even a Problem.

..........................

I mean, really, is 5:40 Plus actually needed or desirable ?? ... Does it Need to Rev it's Proverbials Off ?? ... They and most current ESC's can get Very Hot doing that, whereas using less extreme ratios and making use of the inherent torque, seems to allow things to run cooler (and from recent equivalency testing), also be easier to drive !!

Makes you wonder !!

... Early days,.. guess we shall see, as things develop.

What the NSR guys are doing isn't aimed at average slot racers, running on a variety of tracks.

It's specifically for the top tier racer racing ISRA style cars on flat tracks.

Those racers firmly believe they want their motor to rev to the bejesus, for more gyro effect.

While quite a few racers have complained about the price of the NSR combo, if it proves to be 100% reliable, it would be worth it for the high end racer.

Your statement about the ESC's getting very hot, that must apply to situations with very fast motors.

Others have stated that the ESC doesn't get hot at all.

And speaking of ESC's, it seems like with I see on FB, racers complaining of problems, the ESC producer always ends his post with something like "I'm working on my new, improved ESC, as we speak".

As others have stated, in reality, the people that have jumped on the brushless bandwagon are Beta users.

Of course, "new and improved" is a way of life with slot racing, but with brushless, it will be much, much more so.

When brushless started gaining traction, Richard Mack portrayed it as a super-cheap alternative to $300-$400 motors, with the Eurosport crowd.

People involved in the hobby a long time, like Graham Woodward and myself, scoffed at that.

With the high end, top tier, Eurosport crowd, it was never going to be cheap.

Those racers are going to spend whatever needed to gain a few .01's.

- Tim Neja likes this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559