I agree with pretty everything and everybody in this thread.

If CNC routing was the magic elixir to build commercial raceway and home tracks, there would be ones pre-built, wrapped in shrinkwrap, sitting on pallets, ready to ship.

Routing, while a major part of track construction, still isn't a big enough percentage to encourage the above.

On my 3 tracks, routing was about the only thing I got any satisfaction out of.

Everything else is monotonous, repetitive BS.

I especially like the mindless job of cutting the braid recess.

Speaking of braid recess, on one of the original CNC cut tracks used at the ISRA Worlds, I was told that the CNC cut braid recess was imprecise enough that it created a problem for all but one top racer(but not the best), who unlocked the secret to getting around the varying recesses, and dominated the event.

That said, it certainly makes sense people like Janis Nabokins and Mr. Trax in Australia, who I think are both full time track builders, rely heavily on CNC.

In Mr. Trax'x case, to get his modular tables to line up to be used in multiple configurations.

He might be the exception on having routed tracks, ready to ship, because of that system.

Mike Swiss

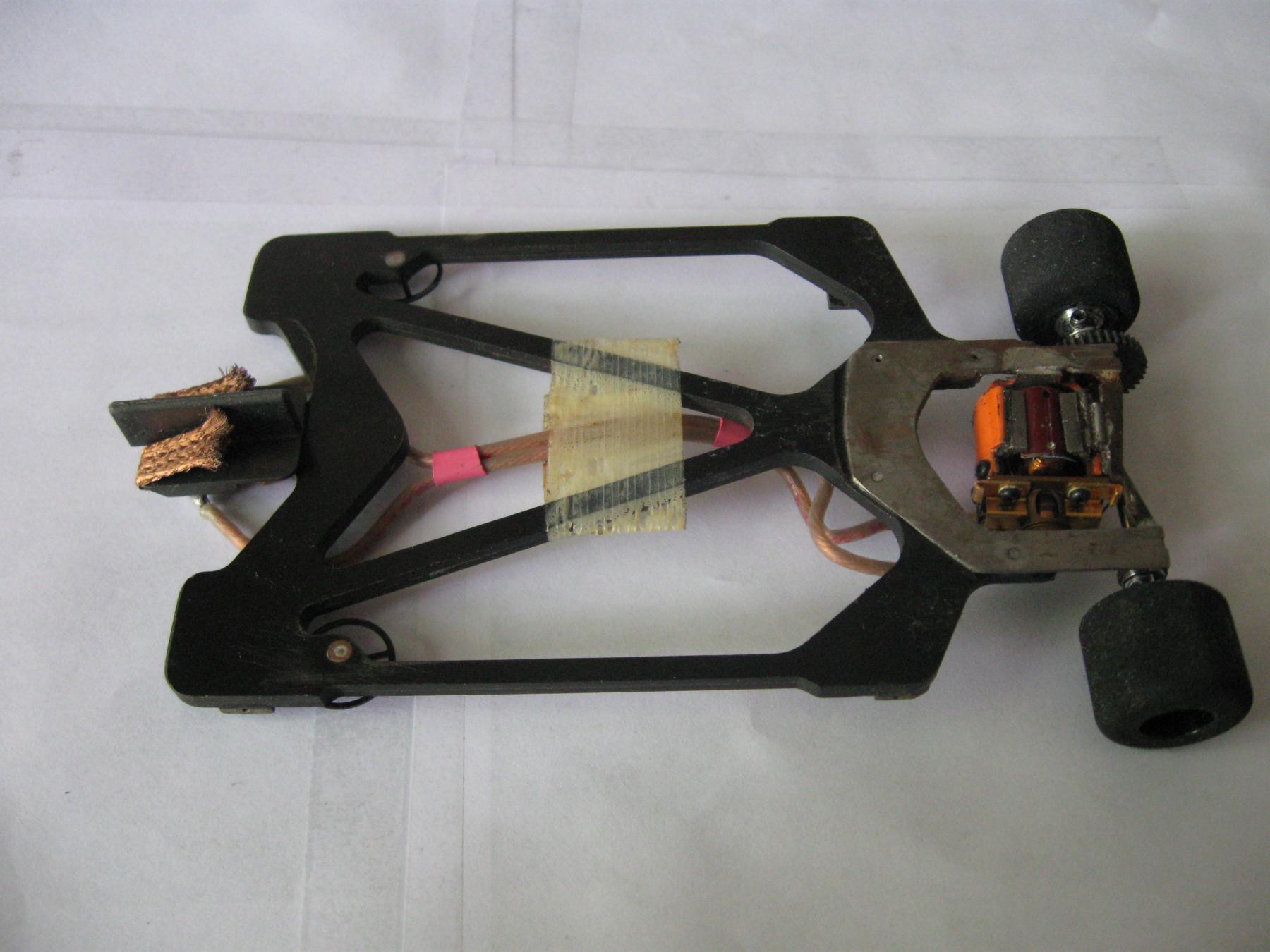

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559