I am looking for information on what is considered the best way to break in the Mid-America Enforcer motor.

The website states "Do not break in on a power supply."

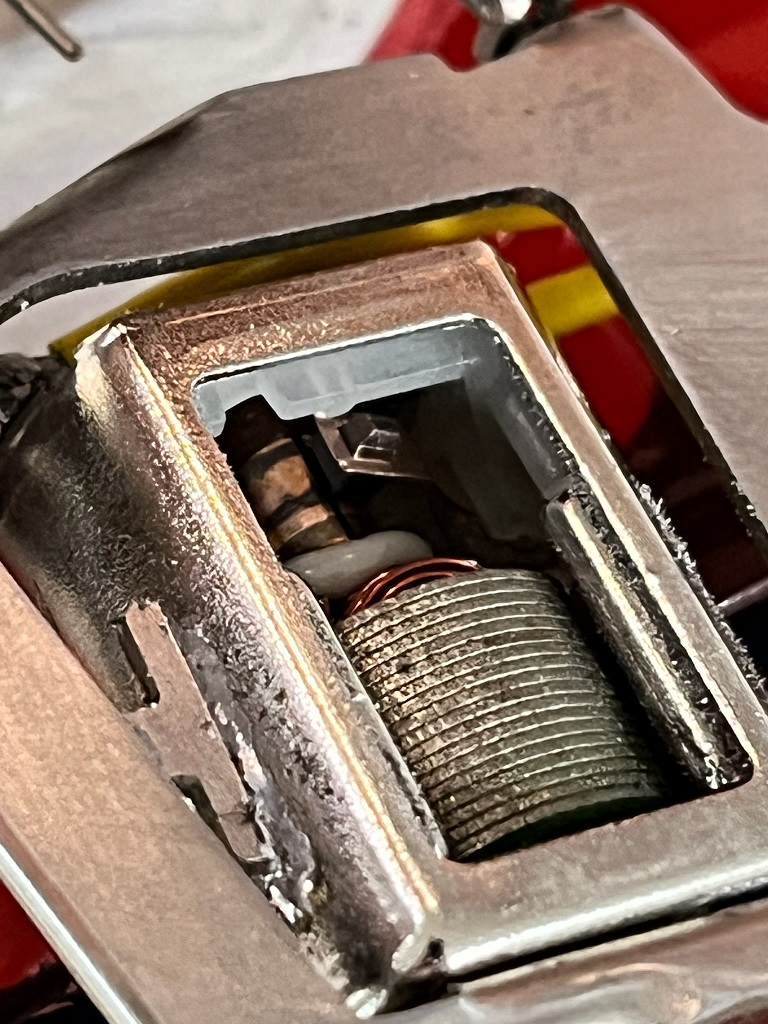

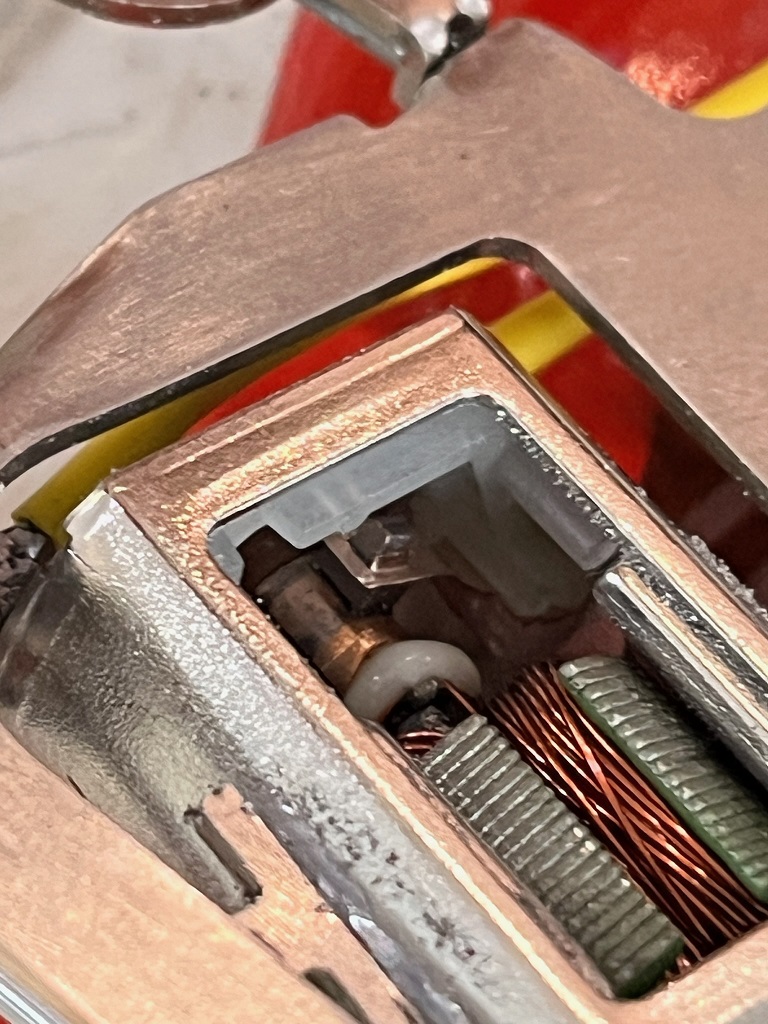

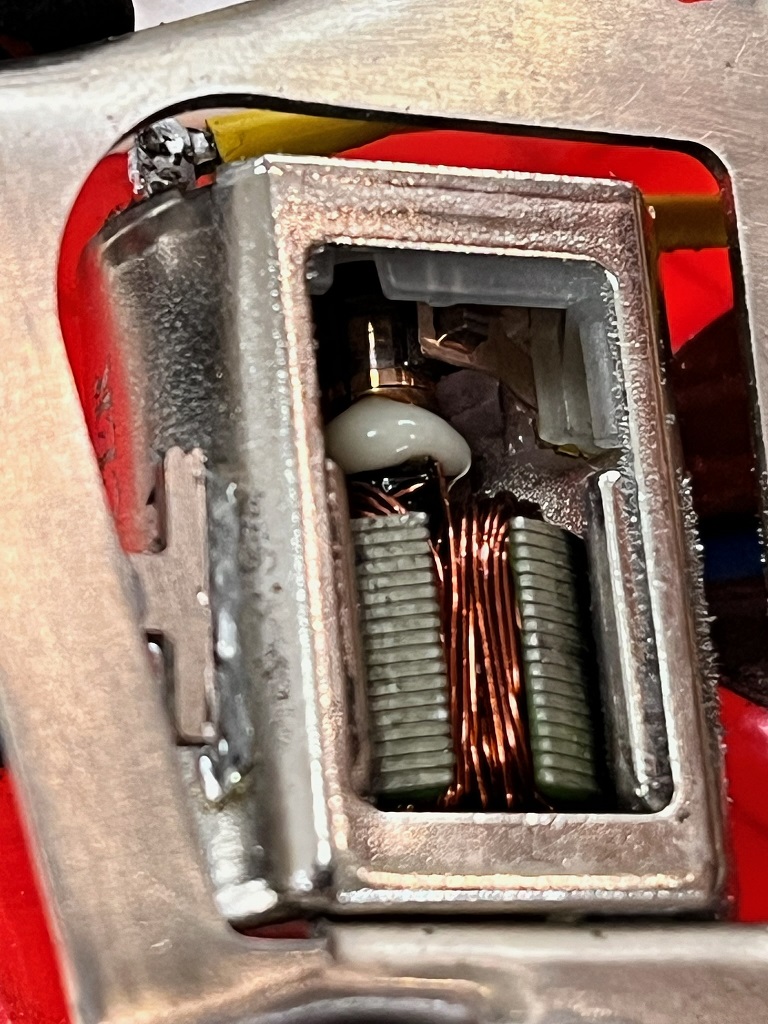

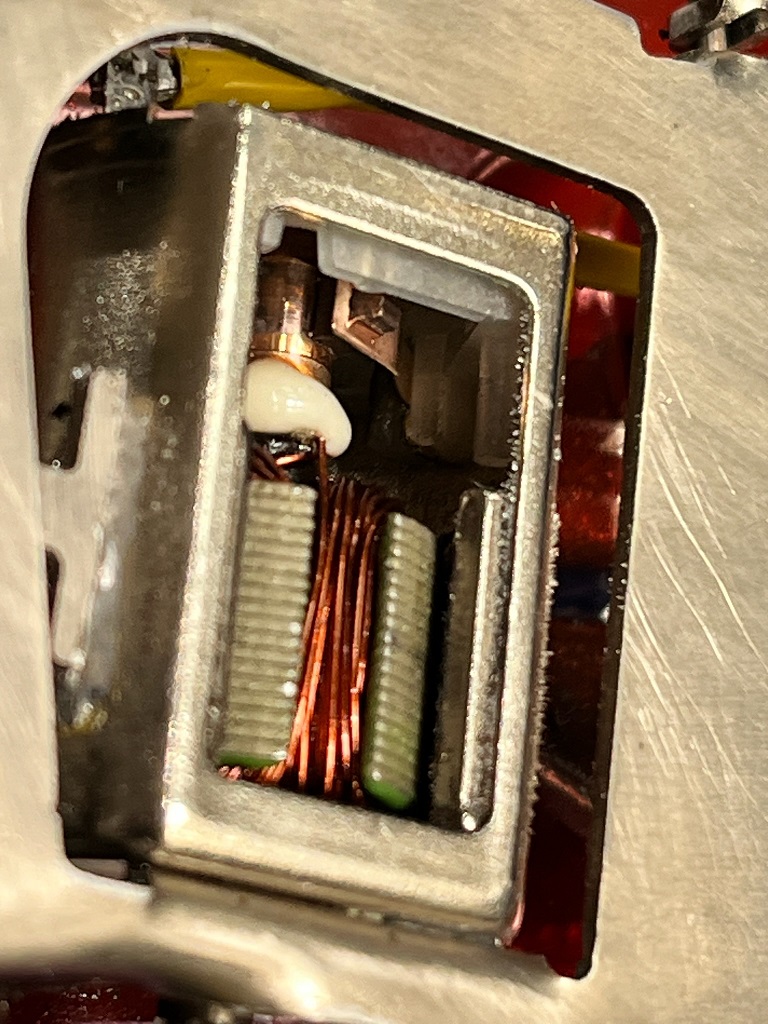

Mid-America Enforcer Monster Motor

I will be running this motor on the Mid-America king track and last I checked the track was set to 13.8v.

Suggestions, ideas?

Thanks.

Mid-America Enforcer motor

#1

Posted 24 June 2024 - 05:53 AM

Started racing slot cars back at the old Grand Avenue Raceway on Grand Ave. in Chicago, Illinois.

Started with Group 12, moved up to Group 27 and Open.

Still have my two cars and over a dozen arms.

Just recently discovered a track local to me and am looking forward to meeting up with the old timers and new people in the hobby.

Bob (B.J.) Reese

#3

Posted 24 June 2024 - 01:46 PM

A drawback of the crimped endbell motors is the limited life caused by the brushes wearing out. Primarily what break-in does is seat the brushes to the comm. Unfortunately, this also shortens the useful life of the motor. By the time the brushes have full contact with the comm, they can be close to half-worn, and starting at around 3/4 worn, the motor starts slowing down.

One of the manufacturers suggested this: install motor in car correctly geared and run 20 laps on track, allow motor to cool completely, then run another 20 laps and cool completely again. The motor is now ready to race.

- Tim Neja, Paul Menkens and breese like this

#4

Posted 24 June 2024 - 02:27 PM

Check with Roger.

#5

Posted 24 June 2024 - 10:14 PM

Break it in with water for about 30 sec at 3 volts, dry it off with compressed air and run it at 3 volts for 5 mins.

First Place Loser in the JK Products

International D3 Builders Competition

#6

Posted 24 June 2024 - 11:30 PM

Bob,

Please don't listen to the above suggestion.

I've never heard of a real FK style motor that can be water broken in for 30 seconds.

- breese likes this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#7

Posted 25 June 2024 - 12:43 AM

Break it in with water for about 30 sec at 3 volts, dry it off with compressed air and run it at 3 volts for 5 mins.

Bob, please don't listen to the above suggestion.

I've never heard of a real FK style motor that can be water broken in for 30 seconds.

It works fine for me – less heat and it does break in the brushes. i wait until the water gets a little dirty, then pull it out. Any more than a minute and you may lose the brushes.

- Ramcatlarry likes this

First Place Loser in the JK Products

International D3 Builders Competition

#8

Posted 25 June 2024 - 04:35 AM

i tried once and lost the brushes perhaps in ten seconds - best to keep the revs really low!

- team burrito likes this

#9

Posted 25 June 2024 - 05:35 AM

Thank you, everyone, for the input.

I think I hurt the first motor by running it a little hard on track when breaking it in.

With this one I am going to run a few slower laps, monitor temp, let it cool down. Repeat a few times....

I have the Carsteen controller with dual chokes. I think I will turn both all the way up at first to restrict low and high speed power.

Started racing slot cars back at the old Grand Avenue Raceway on Grand Ave. in Chicago, Illinois.

Started with Group 12, moved up to Group 27 and Open.

Still have my two cars and over a dozen arms.

Just recently discovered a track local to me and am looking forward to meeting up with the old timers and new people in the hobby.

Bob (B.J.) Reese

#10

Posted 25 June 2024 - 08:49 AM

What's gained by running a motor at low speed on the track versus driving it normally (faster) to break it in? I've been doing the latter with FK motors, and they seem to break in (brushes contour to comm) pretty quickly.

#11

Posted 25 June 2024 - 08:59 AM

The airgaps between the brushes and arm cause arcing thereby causing possible damage to the arm.

Once the brushes are fully seated, the arcing is almost completely eliminated.

I am sure there are others here with more info... It's one reason I asked about this break-in procedure.

- Sloter likes this

Started racing slot cars back at the old Grand Avenue Raceway on Grand Ave. in Chicago, Illinois.

Started with Group 12, moved up to Group 27 and Open.

Still have my two cars and over a dozen arms.

Just recently discovered a track local to me and am looking forward to meeting up with the old timers and new people in the hobby.

Bob (B.J.) Reese

#12

Posted 25 June 2024 - 10:58 AM

I find broken in motors run better. I free run the motors at 1 hour at 4 volts and 1 hour at 6 volts and clean out with alcohol or electrical cleaner. Blow dry, lube bushings very lightly, and go racing. I almost never lube the brush end bushing after initial very light lube.

I agree 100% with Breese above about arcing brushes with new motor.

Bob

- breese likes this

#13

Posted 25 June 2024 - 11:35 AM

What's gained by running a motor at low speed on the track versus driving it normally (faster) to break it in? I've been doing the latter with FK motors, and they seem to break in (brushes contour to comm) pretty quickly.

I've been having better luck just breaking in FK motors by logging laps.

The only time I dip or run them on a power supply is at hand-out motor races. Only because of the limited track time.

- Wizard Of Iz, Tim Neja, Kim Lander and 1 other like this

You're never fast enough!!! 💯

Preparation leads to separation.

Success is never owned but rented, and the rent is due every day.

KELLY RACING 😎

#14

Posted 25 June 2024 - 11:38 AM

I find broken in motors run better. I free run the motors at 1 hour at 4 volts and 1 hour at 6 volts and clean out with alcohol or electrical cleaner.

Run better, as in more constant over longer track times?

My first of these motors over the first 20 or 30 laps got better over time, after that there was a slowdown over a period of time right up to when the motor failed with a broken winding. No real heat visually and the highest temp I remember recording was 119.

Started racing slot cars back at the old Grand Avenue Raceway on Grand Ave. in Chicago, Illinois.

Started with Group 12, moved up to Group 27 and Open.

Still have my two cars and over a dozen arms.

Just recently discovered a track local to me and am looking forward to meeting up with the old timers and new people in the hobby.

Bob (B.J.) Reese

#15

Posted 25 June 2024 - 03:48 PM

What's gained by running a motor at low speed on the track versus driving it normally (faster) to break it in? I've been doing the latter with FK motors, and they seem to break in (brushes contour to comm) pretty quickly.

IMO it can't hurt taking a few easy laps, or even a dozen to 20, to reduce the arcing a bit, getting the brushes a bit more seated, before you run at full speed.

That, of course, unless you are on some super-tight time constraints.

- Tim Neja, Roy Lievanos and breese like this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#16

Posted 25 June 2024 - 03:49 PM

Water break-in and a few other methods people use provide faster break-in because they cause more arcing which burns the brushes in faster. What I'd normally do with a cobalt, C-can, or D-can motor is a long, low voltage run no-load on power supply. An hour at less than 2 volts is common, with a brief buzz up to 4 volts or so 3 or 4 times during this period. I've done this with the crimped motors, and they do run better afterword, but it's also taking away from run-time on the motor.

If you're going to go straight from break-in to racing, this may be the thing to do, but if there's an intention to run some practice or prep laps before the race, that's more wear and can serve as part of the break-in. The main thing is to keep the motor heat from building up with frequent breaks if running on the track, or forced air cooling and low voltage running on power supply. We tend to get impatient running on power supply and jack up the voltage to 3, 4, 6 volts, or use water and get it done in 10 minutes. That's what's hard on the motor and leaves you with an inconsistent or one-race motor.

Also remember that brushes are made from highly-compressed powder and are porous. It's not difficult to damage them. They absorb any liquids they're exposed to which may leave residues behind embedded in the brushes which then with heat cause nasty contamination.

- Ramcatlarry, team burrito, Sloter and 1 other like this

#17

Posted 25 June 2024 - 03:52 PM

Run better, as in more constant over longer track times?

My first of these motors over the first 20 or 30 laps got better over time, after that there was a slowdown over a period of time right up to when the motor failed with a broken winding. No real heat visually and the highest temp I remember recording was 119.

I don't see any connection with not breaking the motor in completely and throwing a wind. That motor was probably just destined to do that.

To be honest, compared to all the stuff we did at Koford for better reliability, considering how cheaply/quickly these motors are made, I'm shocked that they don't fail more often, as fast as they are running these days.

- slotcarone, Rob Voska, John Luongo and 4 others like this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#18

Posted 26 June 2024 - 12:54 PM

Considering all the slot car motors I've owned since the 60's, including US brands Camen, Koford, ProSlot, and Mura, the Chinese arms seem the most cheaply made and more often abused. I think we've become accustomed to the rigors of the US-made product which is superior in most every way, and we expect to be able to do the same things with them and not fail. Considering the difference in price, the Chinese-made arms actually perform suprisingly well and at a bargain price.

As Mike has indicated, a broken wire isn't related to the purpose of break-in. I suppose a thrown comm segment could be related, but I generally think that's from other abuse. I've had well broken in motors lose comm segments, and I think I helped that along with higher voltages. I was experimenting running cars with 14.3 volts, and all of the shed segments occurred during that time.

- Dave Crevie and breese like this

#19

Posted 27 June 2024 - 08:40 AM

I've been having better luck just breaking in FK motors by logging laps.

The only time I dip or run them on a power supply is at hand-out motor races. Only because of the limited track time.

The two Enforcer motors that I've bought didn't get any break-in at all before going in the car. Both felt strong within 10 laps. Must have some pretty soft brushes.

Someone should ask Josh White what he's doing because the Enforcer motor in his GTP is nearly always ballistic.

When we had a local track .... I did exactly what you're suggesting back when we ran JK Falcon 7 and Hawk 7 motors. I'd run 25 laps. Let the motor cool. Run 25 more. Let the motor cool. Run 25 more. After 75 laps ..... it seemed like I'd have a pretty good idea whether the motor was going to be decent or not. Might run 25 more just to be sure. If it was a two-speeder .... I'd take it out and flatten it with a hammer so I wouldn't be tempted to use it again. ![]()

Now with no track nearby ... I run the CR102 motors for 10 minutes at 5 volts. Let it cool for 10 minutes. Then repeat for two or three more cycles. IF I had a local track, then it would just be running laps.

- team burrito, Tim Neja, Eddie Fleming and 1 other like this

Rollin Isbell

#20

Posted 27 June 2024 - 06:01 PM

- MSwiss and Roy Lievanos like this

Started racing slot cars back at the old Grand Avenue Raceway on Grand Ave. in Chicago, Illinois.

Started with Group 12, moved up to Group 27 and Open.

Still have my two cars and over a dozen arms.

Just recently discovered a track local to me and am looking forward to meeting up with the old timers and new people in the hobby.

Bob (B.J.) Reese

#21

Posted 28 June 2024 - 11:50 AM

I found the FNRS General Rules, last edited May 5, 2021

Anyone know of a newer version?

Attached Files

Started racing slot cars back at the old Grand Avenue Raceway on Grand Ave. in Chicago, Illinois.

Started with Group 12, moved up to Group 27 and Open.

Still have my two cars and over a dozen arms.

Just recently discovered a track local to me and am looking forward to meeting up with the old timers and new people in the hobby.

Bob (B.J.) Reese