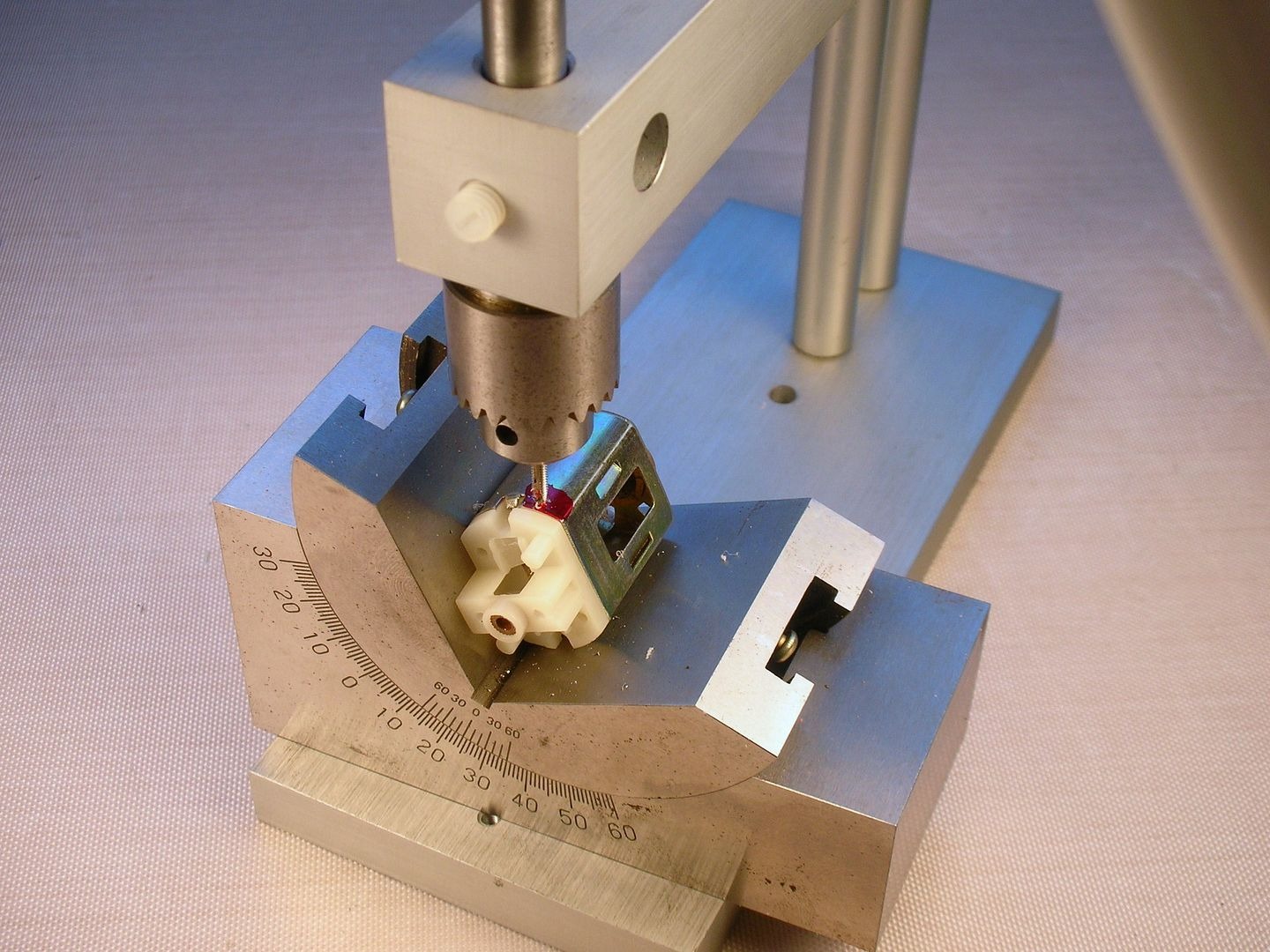

I know we don't do this a lot, but there are times when we have to thread a hole or two, particularly in motor cans. Most of us have threaded them free-hand, and sometimes end up threading it crooked, or worse, breaking the tap off in the hole. Here's how to do it properly;

https://youtu.be/6UO...DkBmpRiDYpOZPZN

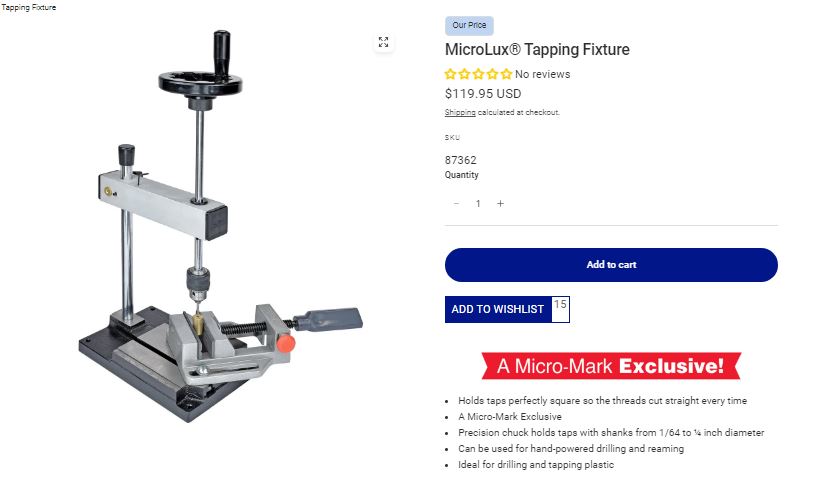

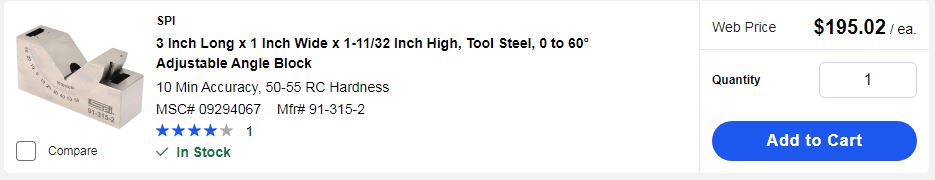

You can get this cheap tapper from MSC Direct;

Or this better one from Penn Tool;

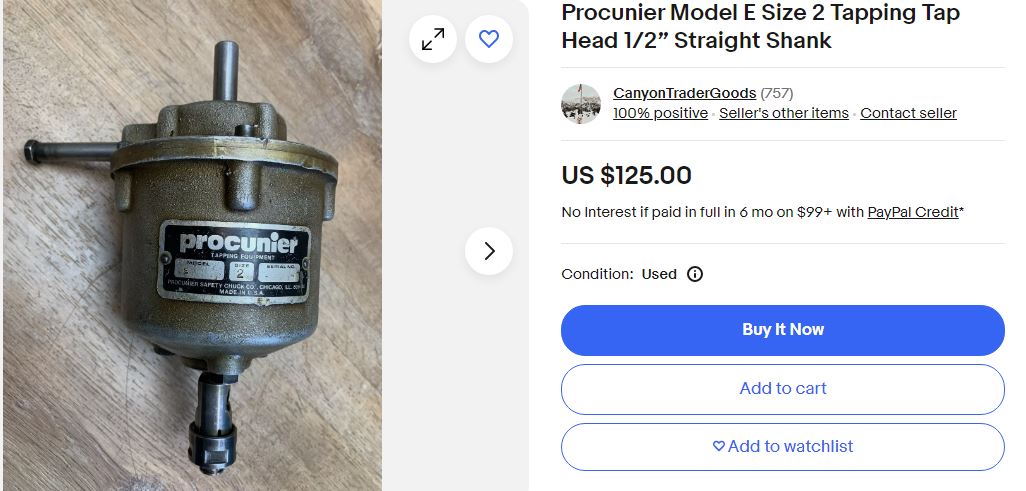

In a situation where you have a lot of holes to thread, you might want to use an automatic tapping head for a drill press;

https://youtu.be/gtY..._QtyeVZqh09kKae

You can find these used on e-Bay;

Now, if you really have a lot of holes to thread, you can go this route. A CNC machining center;

https://youtu.be/Y3f...r1EAkdeaiGCNsvn