Sidewinder Gears

#1

Posted 10 October 2008 - 10:19 AM

1) What's the deal with so-called "drag spurs"? Are these simply larger spur gears that are as durable as any other by the same manufacturer? I see tooth counts that go way up there on these.

2) Is there a resource online somewhere that gives approximate diameters of spur gears so I can figure out what size rear tire would be necessary to keep the spur gear clearance? Having to go to a huge rear tire is also going to mean even higher gear ratios.

Thanks in advance.

#2

Posted 10 October 2008 - 10:27 AM

I have a bunch of the old Weldon (?) sidewinder gears with taper-locks from the '60s... if you can put me in the ballpark on ratio and diameter I'll see what I have.

Don Weaver

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#3

Posted 10 October 2008 - 10:59 AM

John, no reason for a full sidewinder in the first place.

In the second place, you can do the sums yourself.

48 pitch gears mean 48 teeth on a 1" gear. 64 means 64 teeth, 72...

You get the idea.

Fate

3/6/48-1/1/12

Requiescat in Pace

#4

Posted 10 October 2008 - 11:00 AM

Email me at bigpedo@aol.com if interested.

#5

Posted 10 October 2008 - 12:22 PM

Hi Rocky,John, no reason for a full sidewinder in the first place.

But I don't get your answer!? Of course there's a "reason" to do a sidewinder. Aside from the mechanical advantage, it's an "old form" that's not often done anymore. There's no "reason" to do jail-door inlines either... or for that matter floppy-pan inlines

Ah... I thought those designations were the number of teeth per inch on a straight line (so a 48 pitch gear would have teeth 1/48 of an inch) and didn't realize they meant the number of teeth on a 1" diameter gear!In the second place, you can do the sums yourself.

48 pitch gears mean 48 teeth on a 1" gear. 64 means 64 teeth, 72...

#6

Posted 10 October 2008 - 01:00 PM

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#7

Posted 10 October 2008 - 01:13 PM

Oh well... I guess it's close enough for rock and roll!?

#8

Posted 10 October 2008 - 01:20 PM

Google on "pitch diameter" and see what you find.

IIRC the pitch diameter and the overall diameter differ.

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

#9

Posted 10 October 2008 - 01:37 PM

Joe "Noose" Neumeister

Sometimes known as a serial despoiler of the clear purity of virgin Lexan bodies. Lexan is my canvas!

Noose Custom Painting - Since 1967

Chairman - IRRA® Body Committee - Roving IRRA® Tech Dude - "EVIL BUCKS Painter"

"Team Evil Bucks" Racer - 2016 Caribbean Retro Overall Champion

The only thing bad about Retro is admitting that you remember doing it originally.

#10

Posted 10 October 2008 - 01:48 PM

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#11

Posted 10 October 2008 - 02:09 PM

PIC Design

In general, 46t is .750" OD, 48t is .781" OD, and 50t is .813" OD. It doesn't show a 52t gear, so your guess is as good as mine. Hope this helps.

First Place Loser in the JK Products

International D3 Builders Competition

#12

Posted 10 October 2008 - 02:23 PM

Drag gears are often aluminum and don't like too much horsepower for applications other than drag racing. An FK or stock 16D is usually OK. Above that level gear life can be short.

Mike Boemker

#13

Posted 10 October 2008 - 04:31 PM

Hi,

John, no reason for a full sidewinder in the first place.

In the second place, you can do the sums yourself.

48 pitch gears mean 48 teeth on a 1" gear. 64 means 64 teeth, 72...

You get the idea.

Fate

Ummmm, no. Not so much. In 64 pitch, a 1"diameter is going to be 62 teeth.

Quickie formula to find teeth/diameter is. . .

1 divided by tooth pitch, multiply by number of teeth plus 2.

46 example. . .1divided by 64=0.015625". Multiply by 48=.750".

Mike is correct about compressing/expanding teeth to fit a specific diameter. Functions ok a couple teeth on either side of optimum.

Drag gears are good on low HP motors as they are only .040"-ish wide aliminum. For Vintage style big HP rewinds I would try to find Welduns or else use Cox gears.

"Just once I want my life to be like an '80s movie,

preferably one with a really awesome musical number for no apparent reason."

#14

Posted 10 October 2008 - 04:46 PM

Foamy, that makes sense and I'll look into those. Noose's link explained the difference I saw as they measure the pitch diameter about half-way out the length of the tooth.

-john

#15

Posted 10 October 2008 - 05:16 PM

My life fades, the vison dims. All that remains are memories... from The Road Warrior

#16

Posted 10 October 2008 - 05:17 PM

Mongo no read. Teeth-per-inch good enough for Mongo. Mongo sleep now.

I think I'm gonna shoot him!

My life fades, the vison dims. All that remains are memories... from The Road Warrior

#17

Posted 10 October 2008 - 06:50 PM

In a nutshell, Outside Diameter = (Number of teeth +2) / Pitch

Example: Find the OD for a 37 tooth 48 pitch gear...

(37+2) / 48 = 39/48 = .8125

Example: Find the OD for a 69 tooth 64 pitch gear...

(69+2) / 64 = 71/64 = 1.109375

Example: Find the OD for a 52 tooth 72 pitch gear...

(52+2) / 72 = 54/72 = .750

More Info Here... Spur Gear Terms & Calculations

Stock Drive Products

On the above link click > Gears > Spur Gears > Metal

2024 Aluminum

48, 64, 72, 80 Pitch

With Hub / Set Screw

Face Width = .125

Bore Size = .125

At approx $13 each they are a little pricey, but available.

Also Here... W.M. Berg

Bob McCurdy

3/2/54-10/22/12

Requiescat in Pace

#18

Posted 10 October 2008 - 10:03 PM

Mongo look at clouds.

Better.

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#20

Posted 11 October 2008 - 04:33 PM

Wouldn't want to shoot Mongo. It would just make him mad...That's why Mongo no read.

Mongo look at clouds.

Better.

My life fades, the vison dims. All that remains are memories... from The Road Warrior

#21

Posted 11 October 2008 - 08:39 PM

V/R,

Don

Don Berni

#22

Posted 12 October 2008 - 06:54 AM

Thanks again, everyone, for all the information. The above is a nice simple formula (me mongo, too) I can easily use. Thanks, BobIn a nutshell, Outside Diameter = (Number of teeth +2) / Pitch

#23

Posted 12 October 2008 - 09:34 PM

Hi John

In a nutshell, Outside Diameter = (Number of teeth +2) / Pitch

.....

So, can I use this to sort out my 48 pitch and 50 pitch (metric) pinions? It's easy to pick the metric crown and spur gears as they have a 3mm axle hole instead of 1/8", but the pinions are all designed for the same armature shafts. I could never see what the teeth on a pinion all had to be the same length, so I didn't think I could just measure the diameter to sort the metric from the imperial.

Anyway, if your formula still holds for pinions, then a 10t 48 pinion would have an outside diameter of:

(10+2)/48 = 1/4" = .25"

and the metric (approx 50p) would be (10+2)/50 = .24"

I was just last night thinking I needed an 11t metric pinion for a Tamiya. Can I use this formula to find one?

Regards,

Steve C

Stephen Corneille

#24

Posted 13 October 2008 - 01:16 PM

WARNING - WARNING - WARNING

Mongo + Metric = Cranium Cavity Explosion ( Head Go Boom-Boom )

Mongo Watch Whirlie Thingie, Mongo Go Sleep...

Mongo Watch Whirlie Thingie, Mongo Go Sleep...

Mongo See More Whirlie Thingie Here...

Bathsheba Sculpture

Do Not Pass Go, Do Not Collect $200

WARNING ---

Mongo No Read Next Post --- WARNINGBob McCurdy

3/2/54-10/22/12

Requiescat in Pace

#25

Posted 13 October 2008 - 01:17 PM

Hi Steve...Anyway, if your formula still holds for pinions, then a 10t 48 pinion would have an outside diameter of:

(10+2)/48 = 1/4" = .25"

and the metric (approx 50p) would be (10+2)/50 = .24"

Quick Answer... Yes the same formula will work.

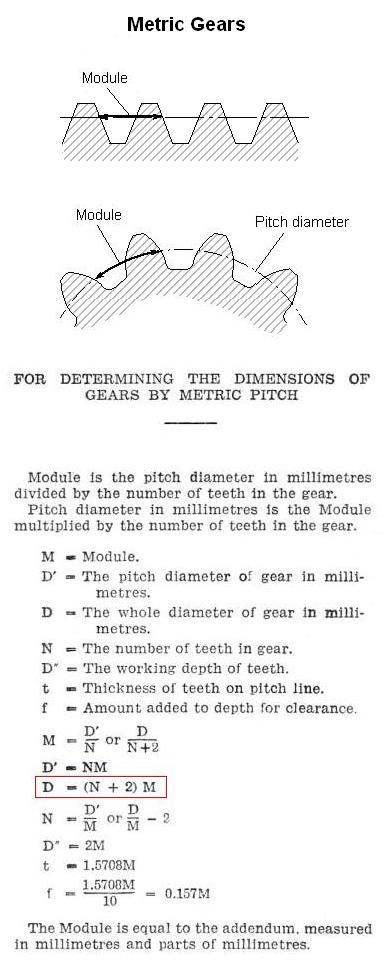

I am assuming that the "approx 50 pitch" gears are actually a 0.5 millimeter "module" gear. (see attached picture for description of metric "module")

A 0.5 millimeter "module" gear would have an equivalent "pitch" of 50.8 teeth per inch ( 25.4 / 0.5 = 50.8 )

Therefore using your example for a 10 tooth pinion: (10+2) / 50.8 = 12 / 50.8 = .2362 inches

If you know the gears module you can use the formula in the pic marked in Red.

D = (N+2) x M

D = (10+2) X 0.5

D = 12 X 0.5

D = 6 mm = 6 / 25.4 = .2362 inches

Hope this helps...

Bob McCurdy

3/2/54-10/22/12

Requiescat in Pace