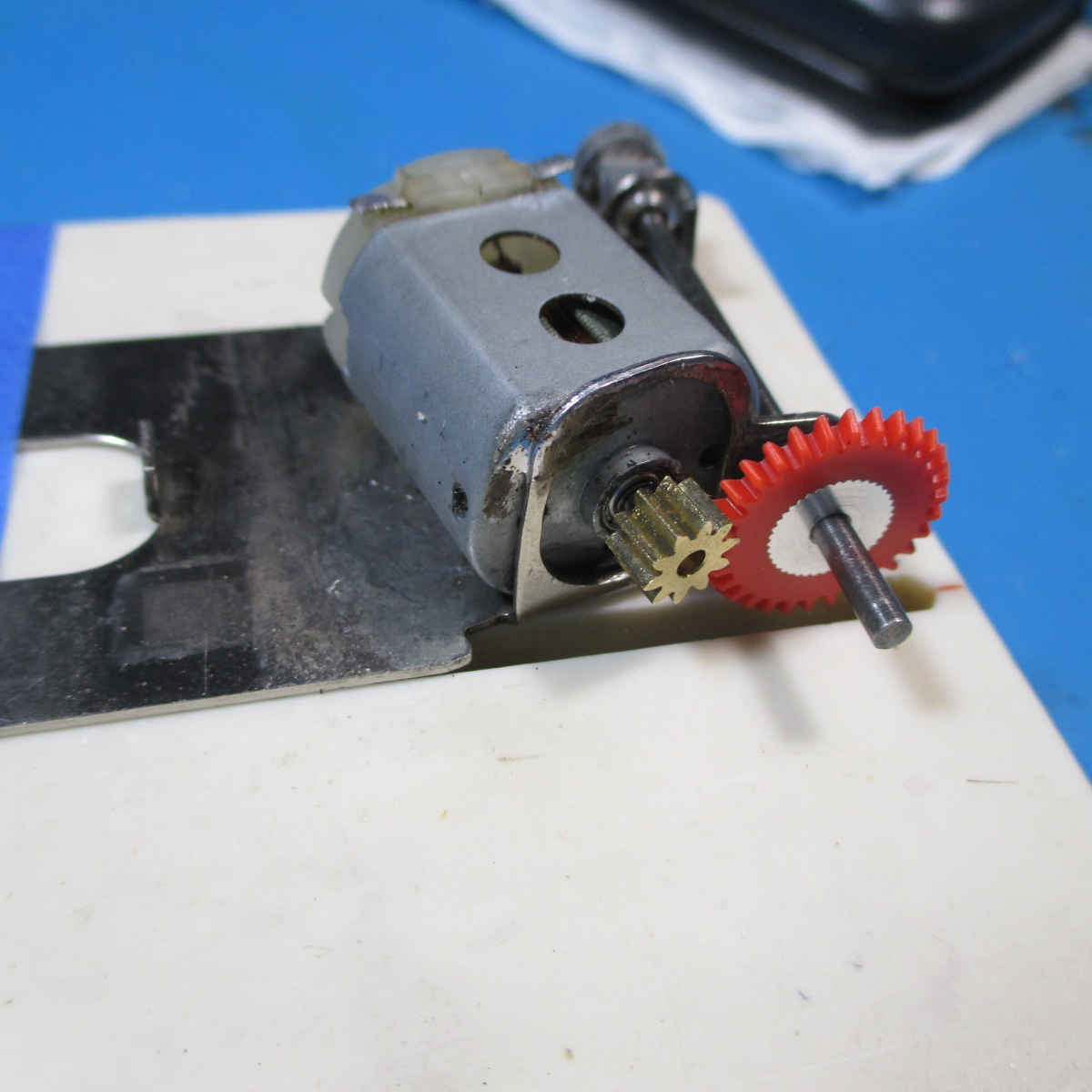

If I were to use a Slot.it spur GA1630E (30 tooth/16mm OD) and a Slot.it 10T pinion, my choices appear to be:

-PI10 5.5mm

-PI6510E 6.5mm

-PS10 6.5mm

The "E" indicates "ergal" I guess but it seems ergal means possibly the cuts of the teeth as opposed to the set screw arrangement?

Does an "ergal" spur require an "ergal" pinion? If so the choice would be the PI6510E I guess.

Also, the PI6510E appears to be steel instead of brass in the catalog photo.

Is it a press-on like the others?

I'm experienced with the crowns but never used one of their spurs, until now. Thanks,

Pablo