Tubing bender/cutter

#1

Posted 24 October 2008 - 07:16 PM

Also, what are you using to cut your tubing/rod?

Just trying to get everything together before I heat the soldering iron up, and give this a go.

Thanks for the info/help.

Norman Johns

Driver of #71

Practice, practice, practice

#2

Posted 24 October 2008 - 07:27 PM

Re bending tube...I dont usually.

Re cutting tube... I used to use sidecutters and then grind the crimped end off in the bench grinder.

Now I'm much more refined and use a dremel cut off wheel,then tidy it up with a light filing.

Cheers John

ps I believe there is a small version of a plumbers pipe/tube cutter available for modellers, but I dont own one.

John Warren

Slot cars are my preferred reality

#3

Posted 24 October 2008 - 07:33 PM

But I haven't seen one for smaller diameter tubing.

Also wondering how you guys are cutting the rear axle tube after it is soldered to the motor bracket.

Norman Johns

Driver of #71

Practice, practice, practice

#5

Posted 24 October 2008 - 07:38 PM

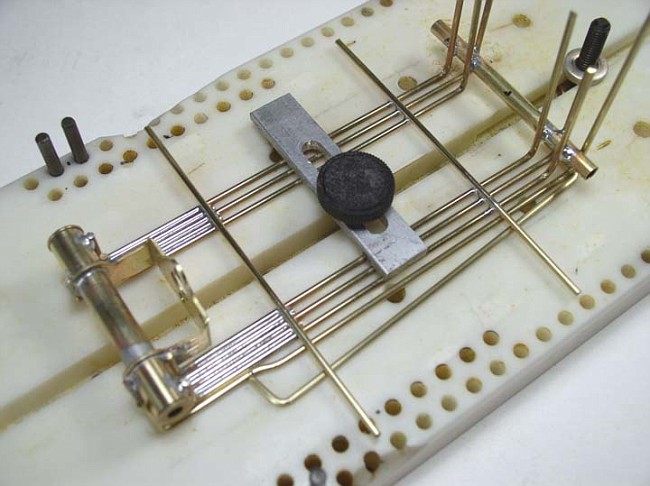

Bending rod doesn't require any special tools...just overbend a bit and then bend back to the finished angle. I never tried bending tubing before...but Steve O'Keefe showed a way to do it right here by sleeving the piece of tubing with the next bigger size and then just carefully making the bend. It works really well on pin tubing, but I haven't tried it on larger sizes.

-john

#6

Posted 24 October 2008 - 07:52 PM

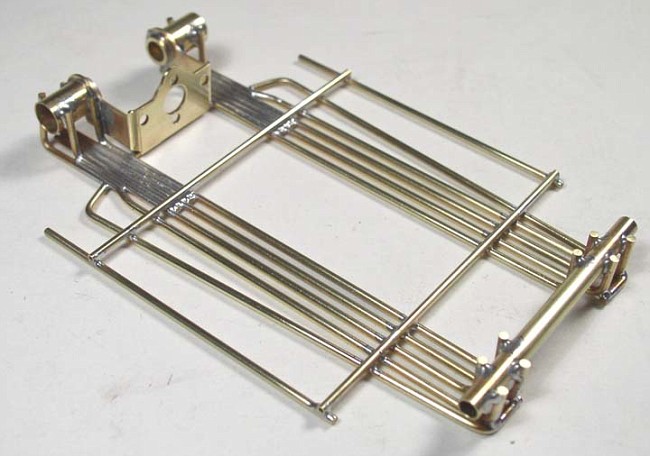

I always cut the rear axle tube to the correct length with a mini tube cutter and center it in the bracket. At some point in the chassis build I cut the center out with a new Dremel cut off disc with no problem. I'm usually racing at HVR wednesday nights if you can make it.

Mike Katz

Scratchbuilts forever!!

#7

Posted 24 October 2008 - 07:58 PM

I intend to live forever! So far, so good.

#8

Posted 24 October 2008 - 09:46 PM

PHIL

#9

Posted 24 October 2008 - 09:54 PM

I found a nice tubing bender at the tower hobby site. It's not the spring bender, it is like the big ones that I have.

I didn't see the Where to get them on the IRRA site last time I was there. I must have missed it. I'll go check again.

Norman Johns

Driver of #71

Practice, practice, practice

#10

Posted 25 October 2008 - 02:30 PM

HAVE FUN!

PHIL

#11

Posted 25 October 2008 - 03:04 PM

http://www3.towerhob...0...LXR791&P=FR

Rick Bennardo

"Professional Tinkerer"

scrgeo@comcast.net

R-Geo Products

LIKE my Facebook page for updates, new releases, and sales: Rgeo Slots...

Lead! The easy equalizer...

#12

Posted 26 October 2008 - 02:09 AM

John Dilworth

#13

Posted 26 October 2008 - 07:48 AM

I intend to live forever! So far, so good.

#14

Posted 19 November 2008 - 02:19 AM

You can alays roll it back and forth under a sharp knife blade ( X-Acto #11) or this:

mini cut off saws are being sold at Harbor Freight for abt $ 27.95 that beats $130 at "Mini Mark"

Bob Blackburn

Rocky Mtn. div retro can am div.

(Spook) Bob Blackburn

#15

Posted 19 November 2008 - 02:22 AM

Iwanted to use stainless, but they won't let me play with it in the Rocky Mtn. retro can am divisionI have the larger tubing benders and cutters. Use to use them a bunch for doing stainless steel tubing.

But I haven't seen one for smaller diameter tubing.

Also wondering how you guys are cutting the rear axle tube after it is soldered to the motor bracket.

(Spook) Bob Blackburn

#16

Posted 19 November 2008 - 02:27 PM

I agree on the safety glasses. When i was young and stupid and build 20 chassis a day I never wore any and never hit myself in the eye. In the last 2 years now that I am old and stupid I have already chipped 2 pairs of glasses and bounced at least a dozen off my face.

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#17

Posted 19 November 2008 - 02:47 PM

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#18

Posted 19 November 2008 - 06:28 PM

That's why I was looking for something small to use, to eliminate the problem.

Norman Johns

Driver of #71

Practice, practice, practice

#19

Posted 19 November 2008 - 11:58 PM

Can you make it to HVR this Sunday for the Retro races?

Mike Katz

Scratchbuilts forever!!

#20

Posted 20 November 2008 - 08:12 AM

I'm not sure yet.

My father in-law is comming over to rebuild my porch roof, and we are doing my daughters birthday party that day also.

Norman Johns

Driver of #71

Practice, practice, practice

#21

Posted 20 November 2008 - 10:43 AM

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#22

Posted 20 November 2008 - 10:50 AM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#23

Posted 20 November 2008 - 11:09 AM

Rick Bennardo

"Professional Tinkerer"

scrgeo@comcast.net

R-Geo Products

LIKE my Facebook page for updates, new releases, and sales: Rgeo Slots...

Lead! The easy equalizer...

#24

Posted 06 January 2009 - 08:33 AM

Never had a chance to find out if it worked or not, though.

Anyone else been told of this?

#25

Posted 06 January 2009 - 11:37 AM

That's a new one to me. Somebody will have to try it to see if it works. Since I already have a set of those K&S spring benders that work okay, I nominate you!

I intend to live forever! So far, so good.