Peck,Stow & Wilcox Co.or Pexto was organized about 1870 in Southington, Conn., later to add offices here in Cleveland,Ohio. they manufactured hand tools to form most of the buildings and such we see today.

I have recently acquired one of these tools made by this company called a bar folder. I knew right away what one of it's many uses,was to make clips and drives for HVAC applications.

Roper Whitney

the knob at the far right adjust the depth of the material feeding into the jaw to be bent,needless to say it was frozen or stuck,the knob on the left sets this pre-determined depth and locks it into place,it was free to turn. I removed all of the screws on top of the blade bending area,with one screw being stubborn not wanting to be removed I wicked a little heat into it after trying to soak it loose with different solvents for several days.

Once the blade was removed it was simply in order for a good ole cleaning of dust, small metal chips,and spider webs. Notice the blackened area for stubborn screw?

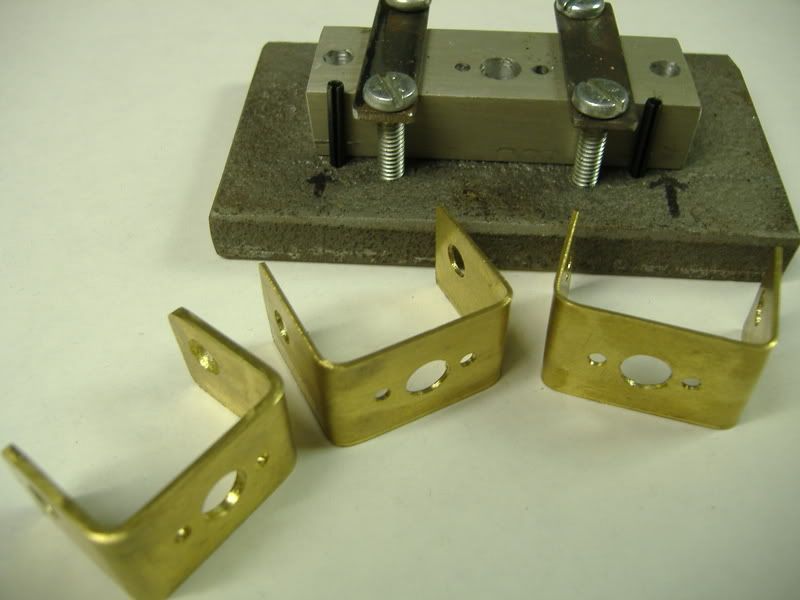

down inside this area I uncovered these three pieces that had been broken off the left side of the folder. HHmmm? I wonder what those pieces do? my only conclusion was there to stop the brake from folding completely over? Such as when wanting to make a 90 degree bend. But how are they arranged?

This is where I need the help of you Slotblog and it's members. Anyone care to take a guess? Even a picture of this model would be of great help. My google searching has left me still searching.

The reason this is of most importance to me is this: the eyeball 90 degree bend is a little tough.

Thank You.