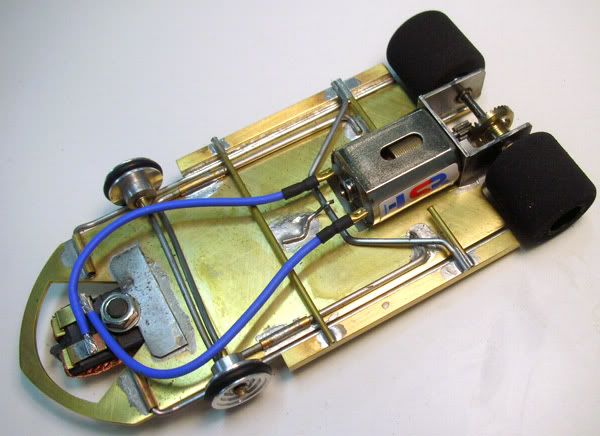

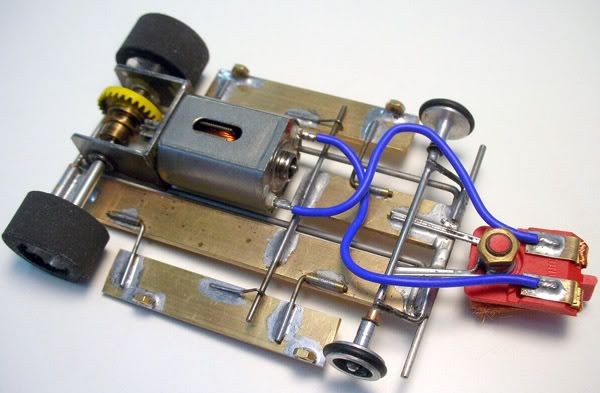

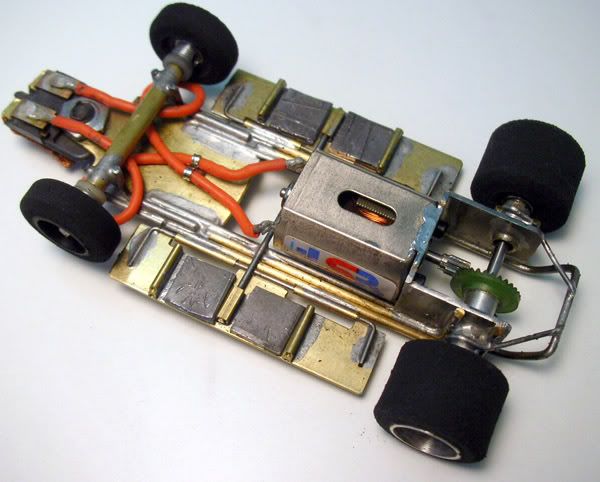

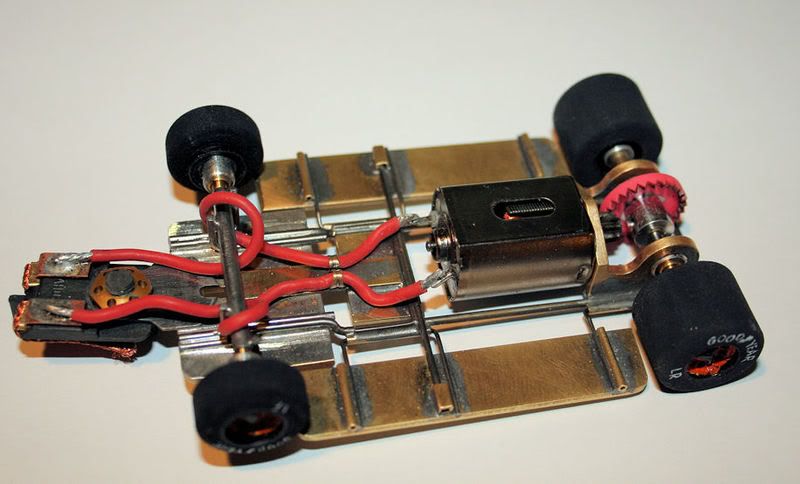

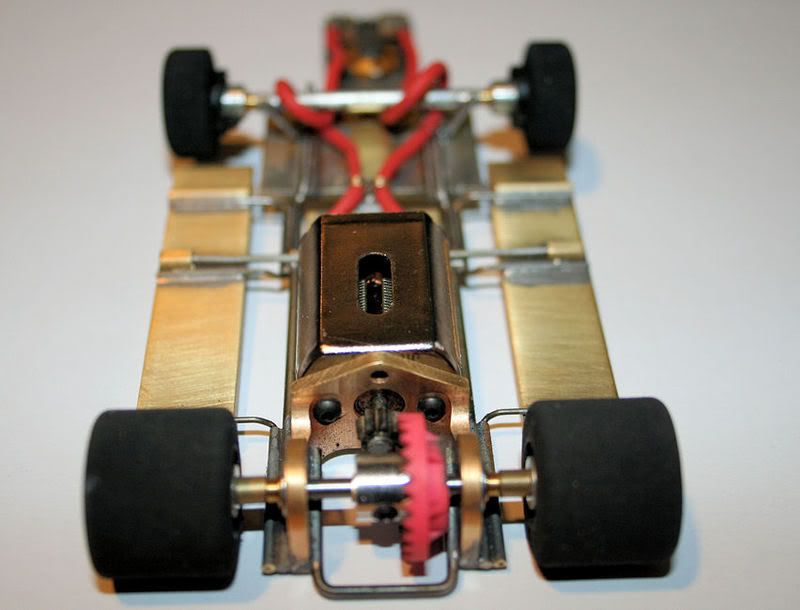

I am glad that the thread actually did come back to the question of mounting the bodies. All that beautyfull "brasswork" shown in the above pictures has been created to take lexan bodies. Mounting hard bodies onto metal chassis I have found can be a very frustrating task, mainly because the hard bodies allready feature mounting postsand they are never quite where they are suposed to be. Also, whenever I thought I had the best place for a bolt or a screw, inveriably there is some plastic bits in the way.

I have, in my very limited experience of mounting chassis to harbodies, made up all sort of contraptions out of sheet brass, carbonfibre, wire and even velcro. Once I just used 2 blobs of blue-tack to attach the body to a beardog chassis. My best success was with glueing 2 or 3 wooden blocks inside the body in a posi where they could be "connected to the chassis" simply with a wood screw.

Every body-chassis-combo will give a different challenge which is what the scratch builder enjoys. Personally I can't be bothered.

If I have a hard body I stick with a plastic chassis and if I have lexan body I stick with metal. Especially considering that these days a top quality plastic chassis can be made to perform very well.

Never mind Nesta, I am saying all this knowing that it won't stop you doing what you like doing.

cheers