Lathe for tire truing

#1

Posted 03 May 2009 - 05:39 PM

Ken Bryan

#2

Posted 03 May 2009 - 05:51 PM

#3

Posted 05 May 2009 - 06:41 PM

mount it, I found that it fits right into the boring bar holder that came with the quick change tool post.

It works OK for the occasional stuff I do, but it would be nice to have something portable.

#4

Posted 05 May 2009 - 06:59 PM

I have had 2 tire truers in 15 years. My latest is the HUDY with the KNOB JOB on it. After you get the JOB. Follow the instructions and you will have a machine that you can walk away from and not worry about. You can duplicate sizes too.....I sold my other one for $40...And ain't lookin back..

AND... The Hudy can fit in your slot box too....

PHIL

#5

Posted 06 May 2009 - 07:36 AM

#6

Posted 06 May 2009 - 07:24 PM

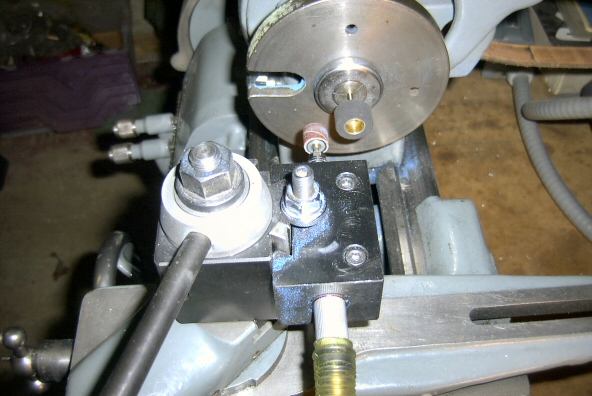

Below is a shot of my first paste-up tire truer. [EDIT: here's the pic! Runs off a 3/8 hand drill, which is too slow. I'll be mounting a die grinder to this next, and a needle parting tool to get large amounts of rubber off before grinding.

For your app, I'm guessing maybe 1600-2000 revs would be better, and MUCH better would be a turning grinding wheel. Can you strap your Moto-Tool to the toolpost to try? Duct Tape if necessary, just try it out. Run reverse of how your lathe's turning, which means run the lathe in reverse, I think...

Question for anybody: the outside flat surface of the donut stock is a different texture--is the rubber there a different consistency, and should I remove that face a good way back? I'm trying to conserve, and I could possibly get two 1/2" tires by parting down the middle, IF this crust isn't too thick. Tell me?

Duffy

1950-2016

Requiescat in Pace

And I am awaiting

perpetually and forever

a renaissance of wonder

#7

Posted 06 May 2009 - 08:22 PM

I'm looking for some ideas along the same lines using a Unimat lathe. I want to be able to trim tires from wheel mounted doughnut to finished tire. Any ideas would be appreciated.

Back in the late 60s. I had a good friend who had a full hobby shop. He had a unimat with every tool,

He made a holder for a no.11 zactro blade so that he could cut tires and have a whole peice and not need a vacum to get all the rubber dust. He got good enough that he could cut, trim and tru a SET of tires in less than 5 min. He also made a tool, with 2 no. 11 blades, that was adjustable, to trim both sides of the tires in one movement. All were mounted in tool post holders that could be lifted out and replaced with what ever tool was needed. When he retired in 75. There were no tracks around and what happened to his 'shop' tools...

OLPHRT.

PHIL

#8

Posted 06 May 2009 - 09:19 PM

I'm looking for some ideas along the same lines using a Unimat lathe. I want to be able to trim tires from wheel mounted doughnut to finished tire. Any ideas would be appreciated.

Before I bought a tire truer (the storied but generally unavailable "Reifenschieffmachin"), I used my Unimat PC to true tires - don't have a photo but it is so simple I think an explanation will do:

I bought a Dremel flexible shaft attachment and bored a hole in a piece of hard maple to just fit - wedged the handpiece of the flex shaft into it and clamped the other end in the tool post - mounted wheel on axle and chucked the axle in a 3/32" collet - mount a sanding drum in the flex tool and grind away!

EM

#9

Posted 07 May 2009 - 09:01 AM