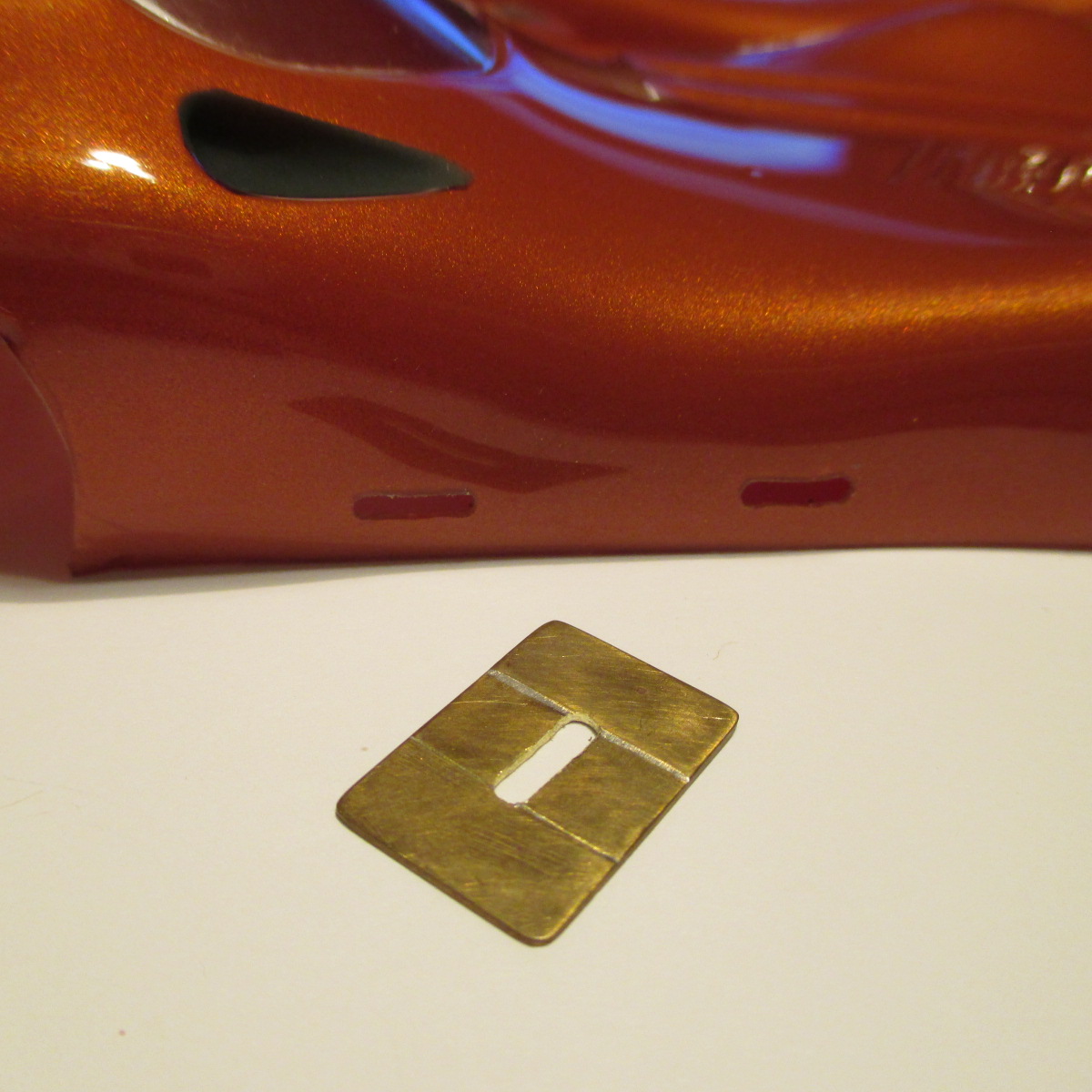

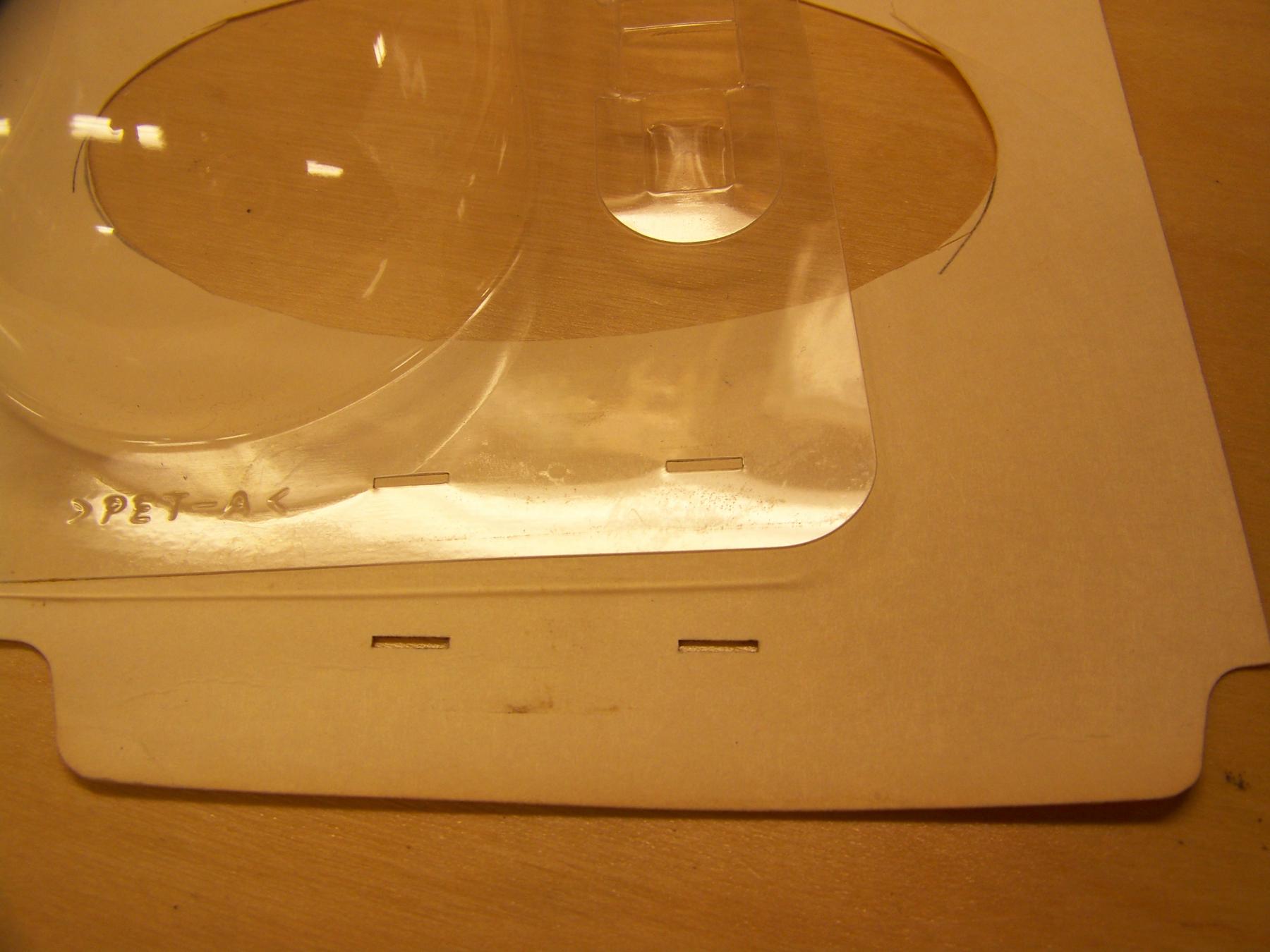

I'm wondering if anybody knows what tool the factory used to punch those rectangular mounting slots on Bandits?

Up to now, I've been using a home made custom template gizmo and cutting them with a combination of harpoon, XActo knive, and a mini-reamer on a dental drill.

It's tedious. I have 13 Bandits in front of me and wish I had a perfect punch to go "boop boop boop boop" and done.

Thanks

Pablo