Motor shop

#76

Posted 10 October 2009 - 12:52 AM

Jeff Easterly - Capt., Team Wheezer...

Asst. Mechanic, Team Zombie...

Power is coming on... NOW!!!

#77

Posted 10 October 2009 - 06:25 AM

To me this is how K&B's 26Ds should have looked years ago

I couldn't agree more Doug ...but they didn't ask me either

-john

#78

Posted 10 October 2009 - 06:27 AM

-john

#79

Posted 10 October 2009 - 08:57 AM

I have some really exciting builds coming up in the next week. Please stay tuned...

Thank you guys for the compliments.

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#80

Posted 10 October 2009 - 09:01 PM

Michael Rigsby

"... a good and wholesome thing is a little harmless fun in this world; it tones a body up and keeps him human and prevents him from souring." - Mark Twain

#81

Posted 10 October 2009 - 10:14 PM

As I say at the beginning of each build post, I'm having "phun". There are some awesome builders here on the blog. I joined less than a year ago and already I've learned stuff and want to learn more. If someone enjoys something I've done, then it makes it all worthwhile.

Stay tuned to this thread...I've got some neat goodies on the way.

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#82

Posted 11 October 2009 - 04:16 AM

You know, until you mentioned it I hadn't really thought of the fact that K&B changed their color scheme for the 26D, so I'm glad you've corrected that!

Excellent job on this motor, and I'm very impressed that you've got a 25 arm drawing only an amp...

Don

#83

Posted 11 October 2009 - 07:01 AM

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#84

Posted 11 October 2009 - 03:01 PM

I need to go prowl the boxes! I THOUGHT I had a 26d in yellow!

on the other hand, I don't remember seeing the AMT 26d!

Sigh.

Or perhaps..

I think I told you all about a local racer looking at one of my newly restored Dynamics. The short version is that in the day in home racing, the stock motor was too much and the commerical trcks weren't running hotter 1/32s! Anyway, so my dynamics all got older 16ds than stock for the milder arms. Using Russkit 22 and 23 cans but with the 32s winds. Anyway, So, running the cars, racing with a friend with one. Local track owner and serious racer (but not serious enough to allow anything but modern plastic stock) said "what is is FOR?" And had no idea what WE were talking about with "having fun.

Chasing down spares for these old things can get expensive and no race program, we must be idiots!

Fate

3/6/48-1/1/12

Requiescat in Pace

#85

Posted 12 October 2009 - 12:35 AM

It seems to me that most all the pros stayed away from the 26D sized motors. But yet, the 26D could have possibly been one of the best motors ever produced for local level racing, particularly among those of us who were teens at the time? I've read story after story (and written a few myself) about how great this little motor performed and all for only $3.00!

- Jesse Gonzales likes this

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#86

Posted 12 October 2009 - 12:00 PM

doug, it was all about the rules!

In 65, I spent the summer with my folks driving around the country. They were visting friedns and such, and I was hitting tracks. Big motors ruled but the tracks usually had some sort of tire rule that looked like 1" rears and 7/8ths fronts. As "the pros' weren't really the customer, but the kids with RTRs and modified RTRs and the popularity of "thingies", the rules were changed to allow some of the Oring, mini wheels and so on thingies to be "legal".

For those of us running in the big races for MONEY, we abused those rules like crazy. For ME, the 26d was a few months one summer until the Hemi and Russkit 23 came out. In the big motor period, the problem with the Russkit 22/sp510 X was the magnets and endbell limited the winds. I built a few small cars for fun, Lotus 7s and the like, but the serious racers were big motors where I could get a lot of horsepower, more than enough.

The smaller 16ds could with a low roll center, not really have much an advantage because of the big scale tire rules. With "thingie" wheels suddenly smaller motors with the lower center had an advantage. With the 26s, 3 bucks, good buy for a kid. For a "pro", though, it was the endbell, (swap out the Pitcan). With the Hemi and better 16d size magnets, and the rules allows 7/8 rear, 3/4 fronts, suddenly the 26d was too tall!

With better magnets, little wheels better endbells and so on, suddenly you could get serious horsepower out of 16d size frankenmotors.

The beginning of the end? could be, "frankenmotors" that would put you in the A or B were expensive.

I remember being shocked by the price of the 36d "707" motor, yet a couple years later, people were paying a lot more for 16d frankemotors!

Fate

3/6/48-1/1/12

Requiescat in Pace

#87

Posted 13 October 2009 - 01:46 AM

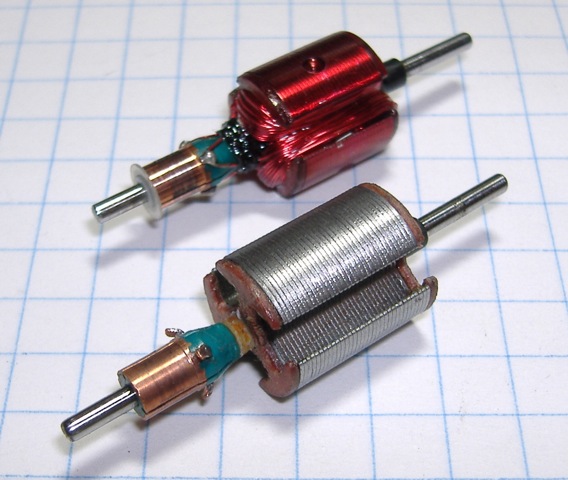

As promised, here's something completely different. I got this motor in a trade with a bunch of stuff recently. There were no labels on it, no cooling holes in the can, it didn't hardly run, but it was hardly used.

It's the same size as the Falcon 7 or Dokk's TSRF motors.

Here's what it looks like all apart. I had already unwound the arm. It had a bizillion turns of "mosquito hair" wire on it. No wonder it didn't perform very well. Probably made for 3 to 6 volt operation.

Here is the arm ready to be wound. I liked the comm on this...certainly appears to be superior to some other similar motors of this size.

65 turns of #30 is on a Falcon 7 and 95 turns of #31 in on another motor in this size, so I wanted to do something in between. I chose 70 turns of #31. Here it is all wound and balanced. None of these motors appear to be epoxied, so I didn't epoxy mine either.

Next, I had to make some air holes for this thing to breathe. HELPFUL HINT: As you grind down a Dremel abrasive cutting disc, before you break it, and it's at least 50% or more worn down, replace it with a new one. Keep the small one so the next time you have to cut a small hole or work in a small area, you'll have a small disc to get in there.

Here it is all assembled and the new cooling holes cut. As much as I liked the comm in this motor, I disliked the brushes. I had to "dink" with them for about 20 minuted to get them where the motor would run properly.

As you can see it draws just a little over 1/2 amp at 7 volts and runs very cool and smooth.

I couldn't just call the motor done even though it was finished. I was just sitting at my desk when i looked off to the side and saw the TSRF motor sitting there with the "TSRF made in China" label on it. Then I thought, TSRF backwards is FRST which almost spells first. Then I thought, I didn't make the motor but I made it better and I live in Oklahoma...and what you see here is my new motor label. NOW the motor is finished or done or half baked or...

Dokk, the label on the side of your motor gave me the inspiration to "finish" it.

Next time we gather around the camp fire I'll show you a couple modern 16D's that have been "kicked up a notch".

See you next time...same bat time...same bat channel.

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#88

Posted 13 October 2009 - 05:53 AM

-john

#89

Posted 13 October 2009 - 09:52 AM

bill from nj

#90

Posted 13 October 2009 - 11:44 AM

I made most of that winder, but the beautiful brass clamping fixture is one of two that were given to me by a blogger (thanks Dave!). I also have another similar one that Rick (RGEO) made that's the whole thing...clamping fixture, crank and stand ready to put in a vise or mount on a base. That one alternates between 26D and 36D arms because I have clamping fixtures for those sizes as well. Ask Rick for one of his brand spankin' new ones in 16D size and you'll be very happy! If he doesn't make them anymore, look for an old LaGanke winder as these are all based on those.

-john

#91

Posted 13 October 2009 - 12:35 PM

The "stock" wind on the FKs can start at ........ghasp, 300 turns of 36! In the FC and FA and FK cans, for a couple decades now, the standard industrial motors start there and for various applicatons get less wire to make spec. Anyway, I have seen 300 down to 160 turns of 36 before they switch to a bigger wire!

The 13uo franken motors, in the day, we usually turned down the early C can endbells to fit in the early 70s with cobalts. In the mid 70s, the brits started casting to size aftermarket endbells for these motors. Impossible to find these days, sadly. But in 73 with cobalts running locally, I had a 13uo with a 25s. I would have gone hotter, but the two local tracks were a black and an orange, and more horsepower was "overkill"..in fact, my fastest cars only used 27s. But with cobalts and good endbells, the size of the motor was an advantage.

Fate

3/6/48-1/1/12

Requiescat in Pace

#92

Posted 13 October 2009 - 12:41 PM

"...the motor madmen that were rewinding every motor they could motor they could get their hands on..."

________________________________________________________________________________

John,

You're describing me to a "T". Back in the day, I would have rewound a horse shoe if I thought it would get closer to the stake.

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#93

Posted 13 October 2009 - 05:57 PM

Hi Bill,

I made most of that winder, but the beautiful brass clamping fixture is one of two that were given to me by a blogger (thanks Dave!). I also have another similar one that Rick (RGEO) made that's the whole thing...clamping fixture, crank and stand ready to put in a vise or mount on a base. That one alternates between 26D and 36D arms because I have clamping fixtures for those sizes as well. Ask Rick for one of his brand spankin' new ones in 16D size and you'll be very happy! If he doesn't make them anymore, look for an old LaGanke winder as these are all based on those.

-john

I am the original owner of my LaGanke and will not part with it...Thank You..

PHIL I.

#94

Posted 14 October 2009 - 12:50 AM

My LaGanke and I go back to 1965 too.

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#95

Posted 14 October 2009 - 12:36 PM

Now made better in OK! These FK cans come in many ways longer and shorter. I have a longer one that did come out of a toothbrush! Good job Doug, you should enter our Frank'enMotor race in Feb with one.

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

#96

Posted 14 October 2009 - 03:36 PM

Back when I helped Mura years ago design their then new motor Woody would spark the shaft with the welder before setting the comms and lock it that way as wrapping and epoxy would lock it on finish.

I have been trying to find one of my old G-Plus HO drag arms to show you guys that they looked like. They looked as if they were wound with coat hanger!

We would show up at a Drag Day monthly race with a couple of handfuls of arms to try to make the last runs! Pancake motors would spark and arc all the way down the track and really put on a show!

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

#97

Posted 15 October 2009 - 12:56 PM

And wasn't it FUN!

Fate

3/6/48-1/1/12

Requiescat in Pace

#98

Posted 15 October 2009 - 02:39 PM

Last time, I promised a couple modern 16D's that have been "kicked up a notch". Due to racing rules and regs nowadays, you pretty much have to run sealed, tagged or otherwise specific motors for specific classes...that is except bracket drag racing. There the field is WIDE open and a place that a rewinder/motor builder can aggressively persue the goal of getting to the finish line first. These two motors are not the fastest I've ever built but they look cool, run great and are definitely a HUGE step up from stock as you'll see. Here's the first motor:

This motor was in pieces as part of a large trade I did about a year ago. I think it was a FastOnes or Slotworks at one time. Any way, the endbell only had a bushing in it...the brush hoods, springs and everything else had been removed. I emailed Ron Hershman and he said he did not sell endbell hardware separately. But Parma does. With just a little bit of fiddling the Parma hardware fits right on. You have to narrow the nose of the endbell slightly where Parma's brush hood base makes the "L" bend and you have to remove the inner halves of plastic shoulders that center the brush hood base to the endbell because Parma's screw spacing is just a cat whisker farther apart than the Slotworks. Screws and springs drop right on. Here's what a Slotworks arm looks like after it has been stripped of it's wire and has been cleaned up.

Today's stock 16D motors come with 70 turns of #30 wire. Radio Shack sells a 3 pack of magnet wire in different colors and sizes. In the package you'll find a roll of bright red #30, a roll of green #28 and Bill from NH's favorite #22. Just ask him about his 15 turns of #22 motors he's built over the years.

I also kicked the timing up a bunch too. Stock is around 20º...this one is at least 35º.

Here are all the parts prior to reassembly

...and the finished product

It looks good and runs good. It might even give a stock Super 16D a good run in a heads up race.

Next, we'll move on to a Parma Deathstar that's had a little more done to it. The stack length of a modern stock 16D is .600". For this motor I wanted to build a short stack. I removed 10 laminations (steel plates) and added some spacers at the end of the arm and between the stack and comm to make up for the loss in length. A stock stripped Parma arm appears in front while the shortened, rewound, epoxied and balanced one appears in the back.

This one got the same #30 red wire but because of the shorter stack length I put 60 turns on it. 60 turns of #30 has been around since 1965 and that's also why I chose it...for old times' sake.

Here we are ready for re-assembly. Just as the motor above, I had disassembled this one for this post. The endbell was originally pink. I don't like pink endbells. This one and others got totally disassembled and dunked in a batch of Rit dye and simmered at very low heat in a pan on a stove for about 30 minutes. I like the way it and the others turned out. The can got a couple coats of Krylon wrinkle black spray paint from a rattle can. I removed the magnets, cleaned them and set them aside. Next, I cleaned the inside and outside of the can with an old toothbrush and solvent. One of those scotchbrite type wheels chucked in a Dremel was used to scuff up the outside of the can. I then masked off the oilite bushing, put the can in a holder and painted it. It then got put in my little toaster oven (used for hobbies only - NO FOOD) and baked for 30 minuted at 150º. The magnets were then re-installed. If you look closely at the brushes you will see an L and an R on then. I do that so if I ever take the motor apart I can put the brushes back in the same way as they came out.

All dressed up and ready to go...

See, if this thing had a pink endbell and a plated can, you probably wouldn't have looked at it for more than 5 seconds. It has been transformed in both looks and performance. I hope you enjoyed these two mills. Good looking and good running motors don't have to be limited the old stuff. Thanks for viewing.

The next time we gather in the parking lot (looking for Dokk and his motors

See you then...same bat time... same bat channel

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#99

Posted 15 October 2009 - 06:29 PM

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

#100

Posted 15 October 2009 - 07:20 PM

-john