As the comm turns

Started by

Champion 507

, Oct 13 2009 12:16 AM

10 replies to this topic

#1

Posted 13 October 2009 - 12:16 AM

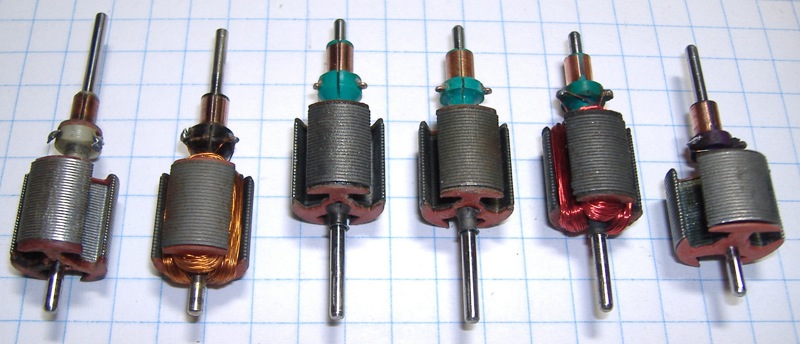

The following picture is what I perceive to be the chronological progression in the development of the commutator Mabuchi used in it's 3 pole slot car motors that utilized an armature that spun on a .078" (2 millimeter) shaft. This represents motors that were manufactured from the early 1960's until about 1968. Without getting into the plethora of all the motor types, I will just generalize by calling them 13D's, 16D's and 26D's. You older guys will know what I'm referring to, you younger guys ask if you don't know. I wish I had a timeline for these comms. At the end of each description I will put the approximate year(s) these comms were produced as signified by example: <1965>. Again, these are round figures and do not represent any written document fact.

The oldest type is on the far left, the newest is on the far right. For the sake of a reference, lets just number them 1 thru 6 from left to right.

1. The oldest type, known for having a very low melting point. It was 3 copper segments surrounding a white low temp nylon hub and all held in place by a red fiber washer. My first attempt at rewinding was on an arm with one of these but it never ran. I melted the comm beyond use trying to solder the wires to it. These comms usually appeared on arms where the laminations (steel plates) were uneven. This kind of armature was similar to what was used in 1.5 to 3 volt toy motors. They could be found in the early Monogram X-100, Russkit 22, Revell SP500 and other similar motors. <thru 1964> The arm in this photo is that of a later type. I do not have an armature with the uneven plates any more.

2. The brown comm, for me, was a BIG improvement. Although not bullet proof, it was made to withstand higher temperatures and rpms and you could solder the wires to it without melting it down. You could find these on the later production runs of the above motors as well as Cox TT-X100 and even some of the early can drive 16D's. I have an original Monogram X-110 that has a brown comm in it. <1965>

3. The first generation green comm. Shaped identically to the previous brown one. While I don't have any specs to back it up, I'm speculating the green ones were made to withstand higher temperatures still. We weren't having trouble with the comms melting (that problem had now moved next door to the endbells) we were having trouble with them shattering and coming apart due to the progression of winding arms with fewer turns of bigger and bigger wire. Our radio/tv solder wasn't staying on as well either due to the increased temps and revs. I really don't think the Mabuchi engineers ever had a clue that their little toy slot car motors would ever be pushed to the electrical and mechanical limits American teenagers and young men were hurling at them. But why should they care? The more we burned up or blew up, the more product they sold...for now. <1965-1966>

4. Second generation green comm. The only thing I see here is that they reduced the bulk of the comm below the solder tabs. Why? Reduced rotating mass of the comm? Maybe. It certainly opened up more area near the comm for the wires to be wound. It looks like the same green material (bakelite?) as the previous one. I have no way of telling if they tried to "up" the internal strength of the comm with this design. I blew them up too! <1966-1967>

5. Third generation green comm. Now the copper segments were fully submerged into the green material instead of being cut. This has to have been done to get the comms to withstand yet more rpms. It would not make any sense to update a design if you weren't trying to improve it. It was around this time that Mabuchi redesigned almost everything on the 16D except the endbell. The can had new oval cooling holes, there were redesigned comms, there were better magnets and there were faster winds being wound on the arms. Heck, they even installed ball bearings in their motors although the quality wasn't there. Even the price for all these improvements hardly went up. But it might have been too late. Good ole American ingenuity and know how from Georgia and California, Champion and Mura respectively, as well as hundreds of motor rewinders from coast to coast were turning the focus to American made parts and less and less to stuff from Japan. This comm., in a slightly shorter length, were the first ones installed on the new 26D's. <1967-1968>

6. Purple comm. To my knowledge, purple comms were only installed in 26D's. These were slightly shorter in length than their regular comm. to accommodate the motor's slightly shorter length. <1968>

This is by no means the "be all to end all" on Mabuchi's comms. I'm sure Dokk will have some interesting things to add. But, I thought I would gather as much as I could and get it all in one spot. Thanks for viewing.

The oldest type is on the far left, the newest is on the far right. For the sake of a reference, lets just number them 1 thru 6 from left to right.

1. The oldest type, known for having a very low melting point. It was 3 copper segments surrounding a white low temp nylon hub and all held in place by a red fiber washer. My first attempt at rewinding was on an arm with one of these but it never ran. I melted the comm beyond use trying to solder the wires to it. These comms usually appeared on arms where the laminations (steel plates) were uneven. This kind of armature was similar to what was used in 1.5 to 3 volt toy motors. They could be found in the early Monogram X-100, Russkit 22, Revell SP500 and other similar motors. <thru 1964> The arm in this photo is that of a later type. I do not have an armature with the uneven plates any more.

2. The brown comm, for me, was a BIG improvement. Although not bullet proof, it was made to withstand higher temperatures and rpms and you could solder the wires to it without melting it down. You could find these on the later production runs of the above motors as well as Cox TT-X100 and even some of the early can drive 16D's. I have an original Monogram X-110 that has a brown comm in it. <1965>

3. The first generation green comm. Shaped identically to the previous brown one. While I don't have any specs to back it up, I'm speculating the green ones were made to withstand higher temperatures still. We weren't having trouble with the comms melting (that problem had now moved next door to the endbells) we were having trouble with them shattering and coming apart due to the progression of winding arms with fewer turns of bigger and bigger wire. Our radio/tv solder wasn't staying on as well either due to the increased temps and revs. I really don't think the Mabuchi engineers ever had a clue that their little toy slot car motors would ever be pushed to the electrical and mechanical limits American teenagers and young men were hurling at them. But why should they care? The more we burned up or blew up, the more product they sold...for now. <1965-1966>

4. Second generation green comm. The only thing I see here is that they reduced the bulk of the comm below the solder tabs. Why? Reduced rotating mass of the comm? Maybe. It certainly opened up more area near the comm for the wires to be wound. It looks like the same green material (bakelite?) as the previous one. I have no way of telling if they tried to "up" the internal strength of the comm with this design. I blew them up too! <1966-1967>

5. Third generation green comm. Now the copper segments were fully submerged into the green material instead of being cut. This has to have been done to get the comms to withstand yet more rpms. It would not make any sense to update a design if you weren't trying to improve it. It was around this time that Mabuchi redesigned almost everything on the 16D except the endbell. The can had new oval cooling holes, there were redesigned comms, there were better magnets and there were faster winds being wound on the arms. Heck, they even installed ball bearings in their motors although the quality wasn't there. Even the price for all these improvements hardly went up. But it might have been too late. Good ole American ingenuity and know how from Georgia and California, Champion and Mura respectively, as well as hundreds of motor rewinders from coast to coast were turning the focus to American made parts and less and less to stuff from Japan. This comm., in a slightly shorter length, were the first ones installed on the new 26D's. <1967-1968>

6. Purple comm. To my knowledge, purple comms were only installed in 26D's. These were slightly shorter in length than their regular comm. to accommodate the motor's slightly shorter length. <1968>

This is by no means the "be all to end all" on Mabuchi's comms. I'm sure Dokk will have some interesting things to add. But, I thought I would gather as much as I could and get it all in one spot. Thanks for viewing.

Doug Azary

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#2

Posted 13 October 2009 - 11:51 AM

Hi Doug,

I was given some "#6" coms not long ago and the arm (even though it wasn't at all a crazy wind) only got to around 4V before the com flew apart making a real mess inside the endbell Gotta love Mabuchi

Gotta love Mabuchi

-john

I was given some "#6" coms not long ago and the arm (even though it wasn't at all a crazy wind) only got to around 4V before the com flew apart making a real mess inside the endbell

-john

John Havlicek

#3

Posted 13 October 2009 - 01:08 PM

Nice post!

But ( I hated to ) the 26D motor was released in late 1966 but may well not have reached all tracks till 1967.

) the 26D motor was released in late 1966 but may well not have reached all tracks till 1967.

The comms, ball bearings, and endbell was fine on the 26D and 16D ball bearing oval hole motors as long as the motors remained stock! Those two motors became the backbone of our local program for around three years. The motors were closely checked for "stockness" and thus they usually lasted till the comm got too out of round, usually about six or seven hours, and would slow down.

But ( I hated to

The comms, ball bearings, and endbell was fine on the 26D and 16D ball bearing oval hole motors as long as the motors remained stock! Those two motors became the backbone of our local program for around three years. The motors were closely checked for "stockness" and thus they usually lasted till the comm got too out of round, usually about six or seven hours, and would slow down.

Don Hollingsworth

11/6/54-2/13/18

Requiescat in Pace

11/6/54-2/13/18

Requiescat in Pace

#4

Posted 13 October 2009 - 02:01 PM

John and Don,

Thanks for your comments. My early racing career ended in mid 1968 when the local track closed. We raced on a Stan Engleman 220' and it was a blast. I had gotten one of the new Champion 5001 "Thumper" motors (oval hole can, ball bearings, etc.) shortly after they came out and had rewound it using ALL stock parts that came on the motor. This was at the end of the inline chassis days, just before anglewinders. Anyway, a friend of mine and I were running some hot laps side by side on the 2 center lanes one day. My car had the horsepower down the straight as I would pull him by three feet going into the bank. His car had the handling as he would pull up right beside me on the lead on and we would be dead even starting down the main straight again. I must have been in orange because I was in the upper lane in the bank. He must have been in blue. We went tearing off down the main straight again and right in the middle of the bank my car locked up, the back end started sliding down the bank, he was so close and it happened so fast he didn't have time to react and...BLAM!. Both of our cars came crashing down to the catch boxes below the bank. We both looked at each other and wondered what the heck happened. Upon retrieval of the carnage I looked inside my motor and saw what happened...dozens of green fragments, copper pieces and a few shreaded windings. I had indeed found and reached the breaking point of that Mabuchi comm (#5 above). Ah, the good old days...don't you love 'em?

Thanks for your comments. My early racing career ended in mid 1968 when the local track closed. We raced on a Stan Engleman 220' and it was a blast. I had gotten one of the new Champion 5001 "Thumper" motors (oval hole can, ball bearings, etc.) shortly after they came out and had rewound it using ALL stock parts that came on the motor. This was at the end of the inline chassis days, just before anglewinders. Anyway, a friend of mine and I were running some hot laps side by side on the 2 center lanes one day. My car had the horsepower down the straight as I would pull him by three feet going into the bank. His car had the handling as he would pull up right beside me on the lead on and we would be dead even starting down the main straight again. I must have been in orange because I was in the upper lane in the bank. He must have been in blue. We went tearing off down the main straight again and right in the middle of the bank my car locked up, the back end started sliding down the bank, he was so close and it happened so fast he didn't have time to react and...BLAM!. Both of our cars came crashing down to the catch boxes below the bank. We both looked at each other and wondered what the heck happened. Upon retrieval of the carnage I looked inside my motor and saw what happened...dozens of green fragments, copper pieces and a few shreaded windings. I had indeed found and reached the breaking point of that Mabuchi comm (#5 above). Ah, the good old days...don't you love 'em?

Doug Azary

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#5

Posted 13 October 2009 - 04:34 PM

Yeah...what fun  I can vouch personally for the complete unsuitability of #6 for anything above a #33 wind to be used in an electric toothbrush...occasionally

I can vouch personally for the complete unsuitability of #6 for anything above a #33 wind to be used in an electric toothbrush...occasionally

-john

-john

John Havlicek

#6

Posted 14 October 2009 - 11:17 PM

John,

I've still got one or two stock 26D arms I rewound years ago that still have the purple comm on them. I think I used to race them in 1968. Of course if I put the motors all back together again and dropped them in a car, the comms would probably "grenade" half way down the main straight on the first lap. Oh well....

I've still got one or two stock 26D arms I rewound years ago that still have the purple comm on them. I think I used to race them in 1968. Of course if I put the motors all back together again and dropped them in a car, the comms would probably "grenade" half way down the main straight on the first lap. Oh well....

Doug Azary

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

"We offer prompt service... no matter how long it takes!"

"We're not happy unless you're not happy"

"You want it when?"

#7

Posted 14 October 2009 - 11:47 PM

OOOO GOD.....My first dewind was a white plastic comm..... I had heard how BAD they were. Took 10 turns off and a quick solder job.....Made one race and 15 min practice before it melted. Member the black....

PHIL I.

#8

Posted 15 October 2009 - 09:52 AM

In the day, I rewound lots of FT16D and dewound many FT26 arms, using the green or brown stock comms, and none ever failed. Later I used Tradeship comms only because they had better tabs to hold the wire.

Philippe de Lespinay

#9

Posted 15 October 2009 - 10:29 AM

Hi Dok,

Yea but, yea but... those comms were 42 years younger. Hard to believe ain't it!

When you solder any comm, hold the shaft where it's running through the comm. If the shaft gets too hot to hold, the comm may have gotten too hot to hold too! (Pun intended!)

Yea but, yea but... those comms were 42 years younger. Hard to believe ain't it!

When you solder any comm, hold the shaft where it's running through the comm. If the shaft gets too hot to hold, the comm may have gotten too hot to hold too! (Pun intended!)

Don Hollingsworth

11/6/54-2/13/18

Requiescat in Pace

11/6/54-2/13/18

Requiescat in Pace

#10

Posted 15 October 2009 - 12:22 PM

Hi

heatsinks while soldering.

Like P, I had good use out of the greens. I lost a couple, and I have some still running today. In another thread I wined about losing a couple of 32s from the day...finally, but it was a thrown wire rather than the com.

With the earlier leaf types... I had the advantage that my dad was an old electronics geek and on my first wind on a Mabuchin 15r, he suggested thread run through epoxy to wrap the com down BEFORE the rewind. The limit then moved over to the crummy brushes. I recently, just to upset the locals, did a similar mod to a "stock" NC1 back when the locals were certain one could not open the motor because of the wrapper.

Fate

heatsinks while soldering.

Like P, I had good use out of the greens. I lost a couple, and I have some still running today. In another thread I wined about losing a couple of 32s from the day...finally, but it was a thrown wire rather than the com.

With the earlier leaf types... I had the advantage that my dad was an old electronics geek and on my first wind on a Mabuchin 15r, he suggested thread run through epoxy to wrap the com down BEFORE the rewind. The limit then moved over to the crummy brushes. I recently, just to upset the locals, did a similar mod to a "stock" NC1 back when the locals were certain one could not open the motor because of the wrapper.

Fate

Rocky Russo

3/6/48-1/1/12

Requiescat in Pace

3/6/48-1/1/12

Requiescat in Pace

#11

Posted 16 October 2009 - 06:22 AM

If you're overheating a com like that when soldering, you're way overdoing it. With a 15W iron, 60/40 rosin core and good clean parts (scrape the wire and clean all the tabs) you shouldn't have to overheat the com at all. Most likely the age factor (as Don pointed out) is coming into play at this point.

-john

-john

John Havlicek