Anyway, I built many frames in the '80s, but none had the detail wire work as retro frames, especially Jail Door chassis.

What do you recommend as the best chassis jig?

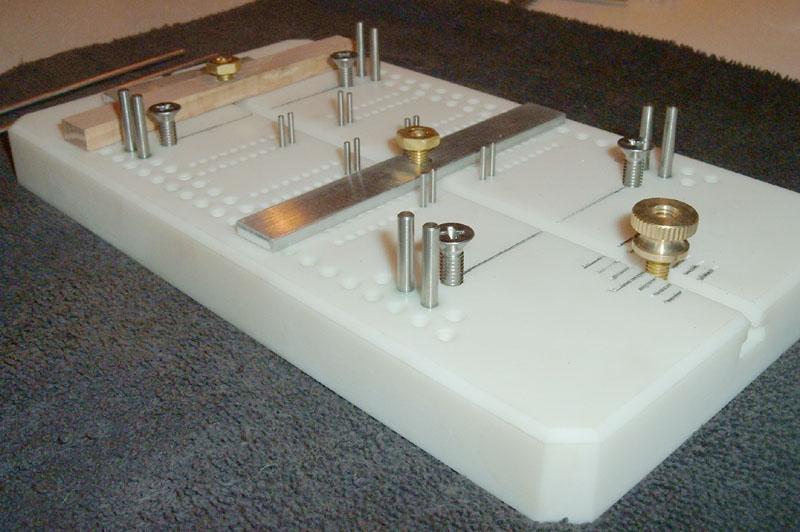

Are any better than THIS ONE?

Thanks for any and all suggestions.

Posted 18 January 2010 - 12:41 PM

Posted 18 January 2010 - 01:10 PM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 18 January 2010 - 01:15 PM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

Posted 18 January 2010 - 01:38 PM

Posted 18 January 2010 - 01:50 PM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 18 January 2010 - 01:56 PM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 18 January 2010 - 02:09 PM

Posted 18 January 2010 - 02:46 PM

Rick Bennardo

"Professional Tinkerer"

scrgeo@comcast.net

R-Geo Products

LIKE my Facebook page for updates, new releases, and sales: Rgeo Slots...

Lead! The easy equalizer...

Posted 22 January 2010 - 09:04 PM

Posted 23 January 2010 - 08:06 AM

Posted 23 January 2010 - 04:30 PM