Hudy comm lathe

Started by

MattM

, Jun 11 2010 05:38 PM

4 replies to this topic

#1

Posted 11 June 2010 - 05:38 PM

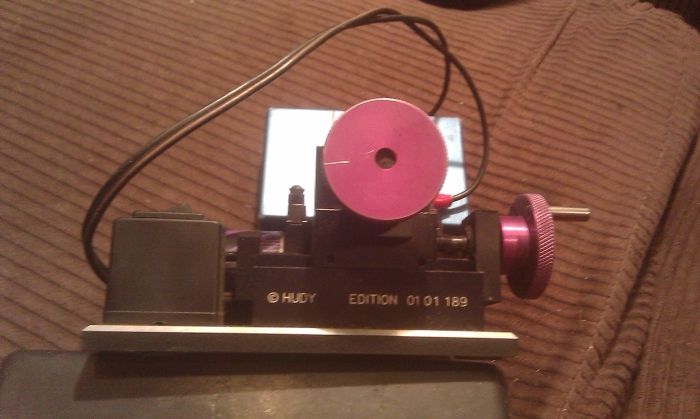

A friend gave me his Hudy commm lathe from his days of racing R/C. I know that its not the slotcar model, but was wondering if its possible to use for slotcar comms, and if not, is it possible to convert over to slotcar use?

Matt Mettler

#2

Posted 11 June 2010 - 06:27 PM

If you can post a picture that would help. Some of the Hudy RC lathes used armature supports that used rollers instead of a V-block that is common on the

slot car lathe. The roller type armature support doesn't work for a slot car as it's make for a larger diameter shaft. You may have to make a couple of mods to get it to work on slot car armatures, but you really need to post a pic so we can tell what model you have, and if its worth it.

Michael Rigsby

slot car lathe. The roller type armature support doesn't work for a slot car as it's make for a larger diameter shaft. You may have to make a couple of mods to get it to work on slot car armatures, but you really need to post a pic so we can tell what model you have, and if its worth it.

Michael Rigsby

"... a good and wholesome thing is a little harmless fun in this world; it tones a body up and keeps him human and prevents him from souring." - Mark Twain

#4

Posted 12 June 2010 - 05:49 PM

When you get it to work you may need a Hudy rubber belt kit (o-rings) to be used with slot car arms. Look in the "Motor Building Tools" section of the website to find the right ones.

www.e-slotcar.com

then click on "shop online" at the top of the page to enter the catalog.

www.e-slotcar.com

then click on "shop online" at the top of the page to enter the catalog.

Scott Salzberg

PCH Parts Express

#5

Posted 13 June 2010 - 06:24 PM

Kinda hard to tell from the pictures, but it looks like the does have the V-block style uprights instead of the roller type, which means slot car arms will turn ok as long as the right standard will adjust in enough to support the slot car armature properly. At this point, put a slot car armature on it, maybe an old 16D arm, with the comm on the right side and see if that upright will move in enough. I use a .020 armature spacer on each end of the armature to protect the arm from the V-blocks. You move the right upright by loosening the allen head screws on the bottom. Use a dial caliper to make sure the upright is parallel to the left side if it moves in far enough. Like Scott said, get a new set of O-rings for it and make sure the lathe bit is in good shape and practice on old armatures first.

Michael Rigsby

Michael Rigsby

"... a good and wholesome thing is a little harmless fun in this world; it tones a body up and keeps him human and prevents him from souring." - Mark Twain