Building a JD sports and JD F1 for Ramcat Larry, one F1 for Bill ( does my machine work ) and the last F1 is mine.

All I can say I would rather build just about any Retro chassis other than these. One of the hardest builds ever. I haven't figured out how to keep all the rods from falling over on top of each other before using the jigs clamp? Worse yet was trying to figure out where I wanted the brass rods to go? Normally I would have used ACad, but was scolded by PM that you don't CAD JD chassis

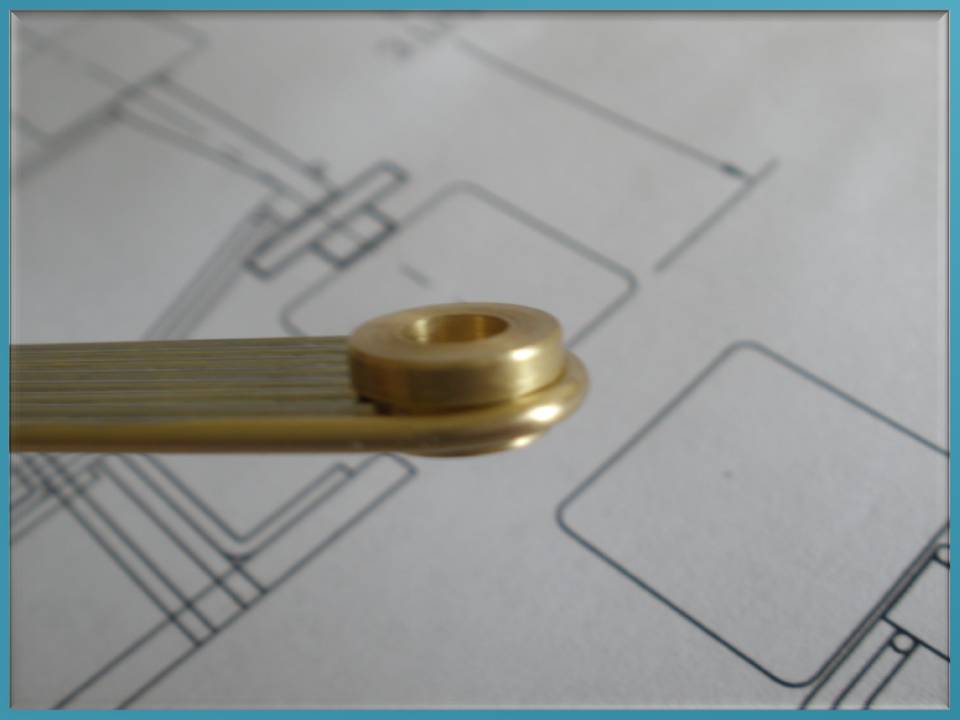

Next will be adding the pin tubes to the F1's and make and bend the drop arms.