I'm a mechanical design engineer by day, but after I got a Scalextric set for our kids my interest in slot cars got fired up again. I'm no model maker but I've designed plenty of things more complicated than a slot car - how hard can it be?

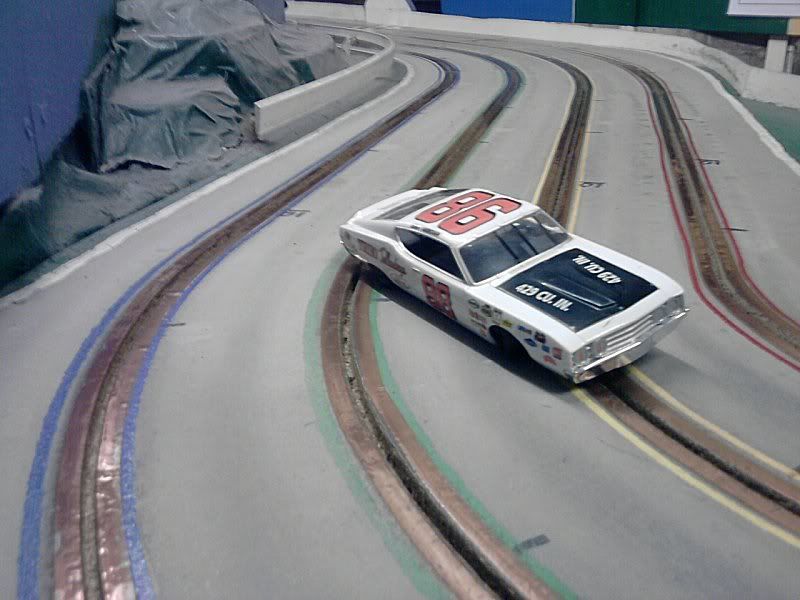

The competition to make a fast car is as fierce as in any other sport or hobby, but that's not what I'm looking for. You'll perhaps agree that your favourite car isn't necessarily the fastest, it can be something else which gives that special grin on your face as you put it on the track. I wanted to make something that was in the car chases on TV when I was a kid - a good sized American car, lots of tail slides, out of control at 40mph... for anyone who grew up with 1970s and early '80s TV, you know what it was like.

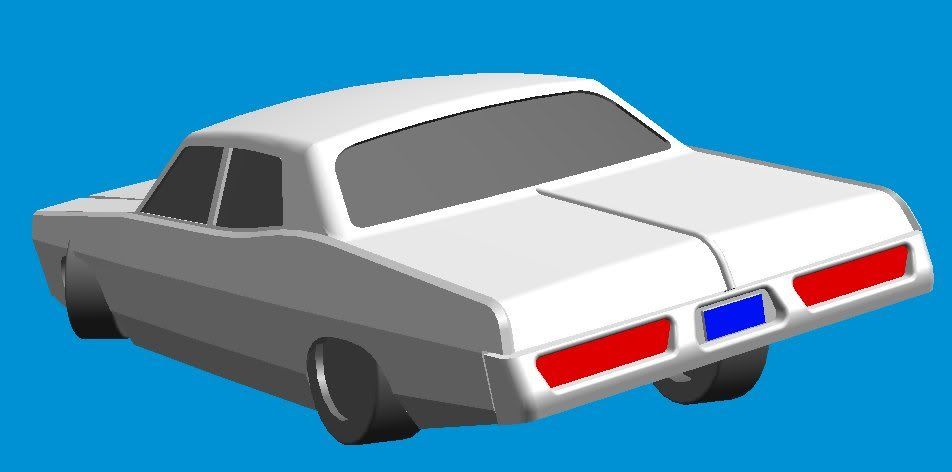

To the car. I love the shape of the '77 Dodge Monaco; it's got a fine history in TV and films, looks a good shape and nobody does one at the moment.

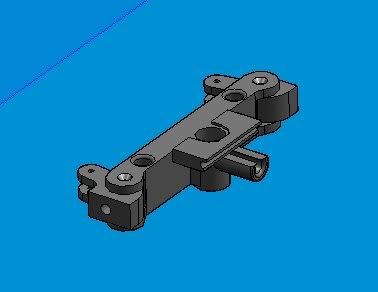

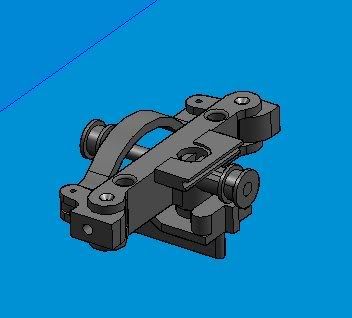

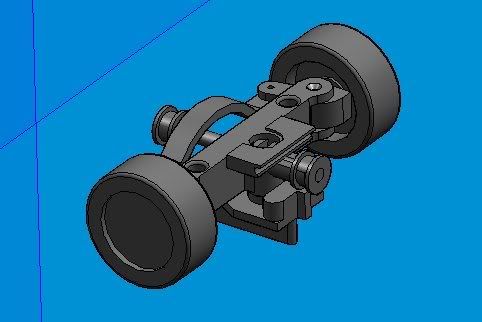

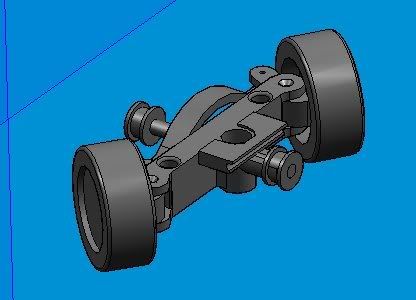

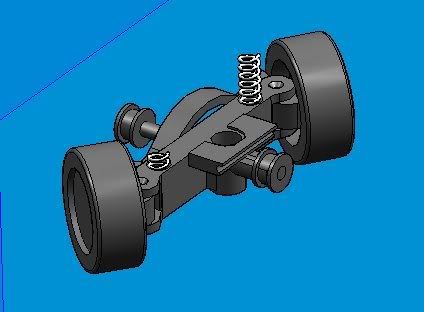

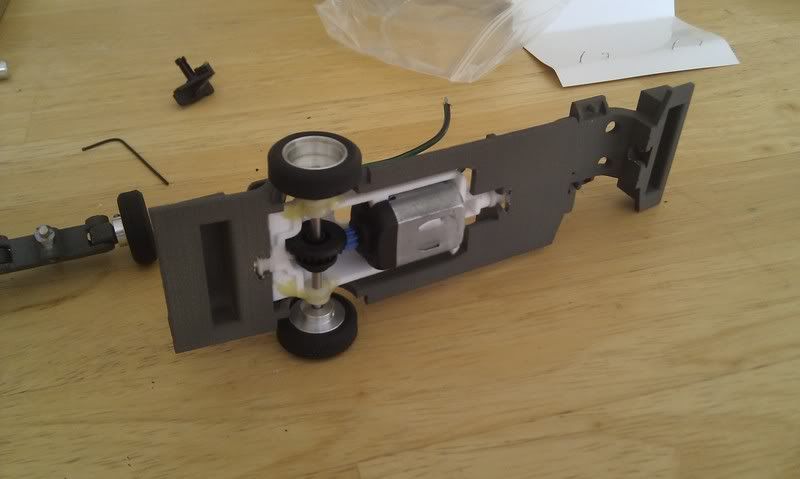

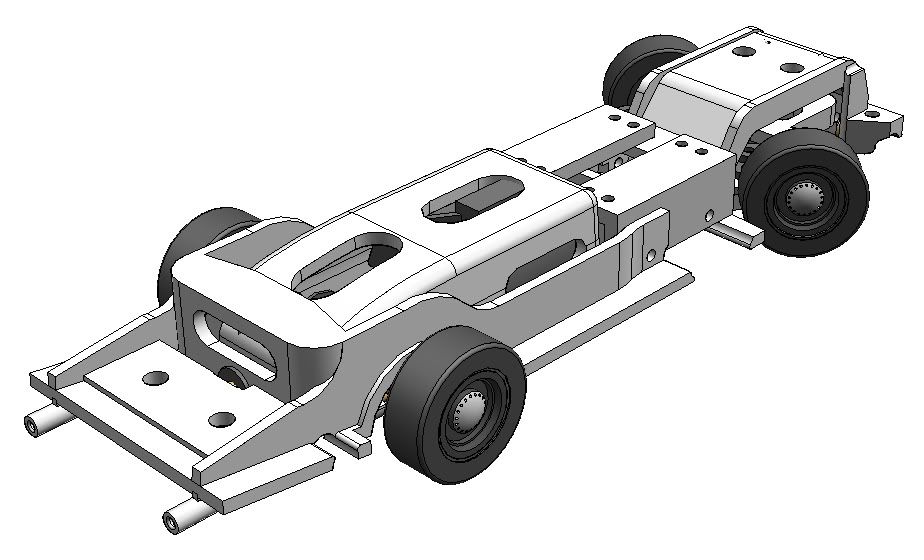

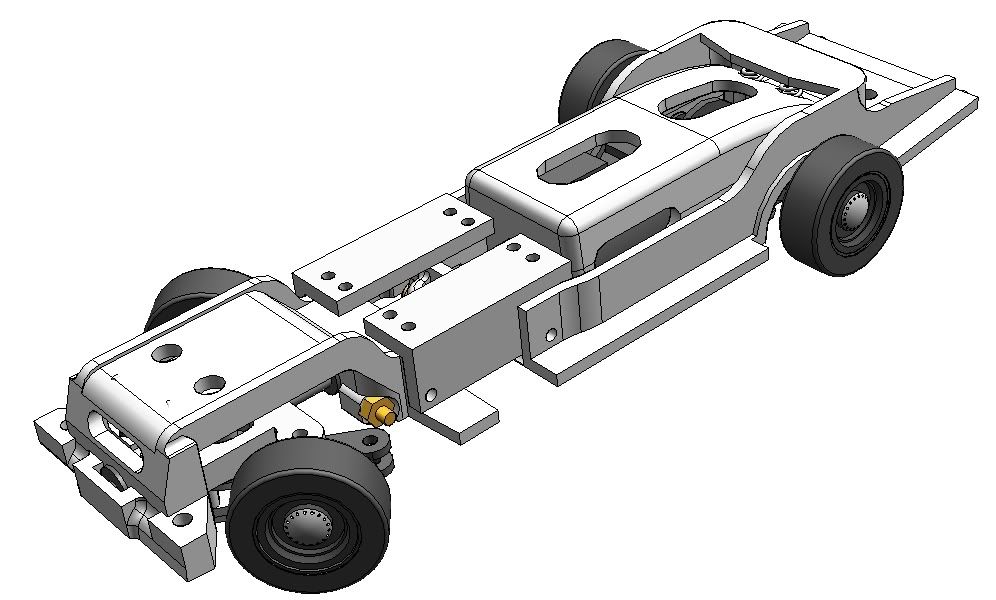

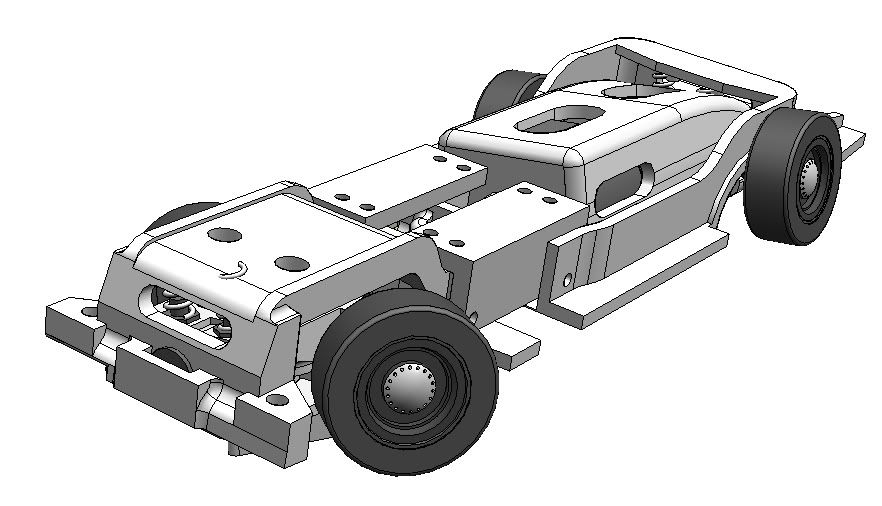

Now for the specification – it should have suspension that lets it lean realistically in a curve. The roll centre of a solid rear axle is easy to find, we'll make the roll centre of the front suspension at the same height so it doesn't have a roll gradient.

It should have steering, this is essential when doing huge power slides and even just when on tight corners. I just think it looks fantastic, so you'll have to humour me. You don't mind?

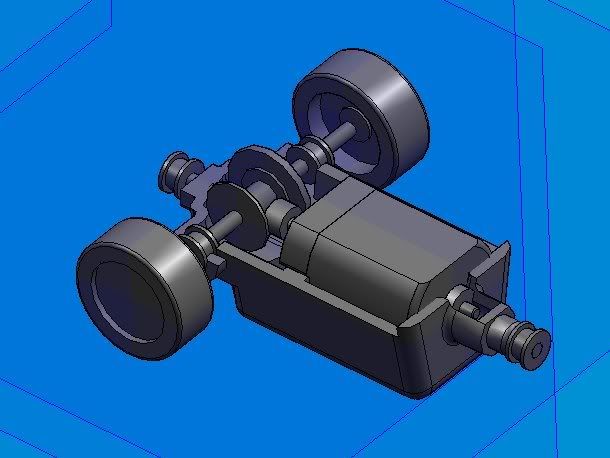

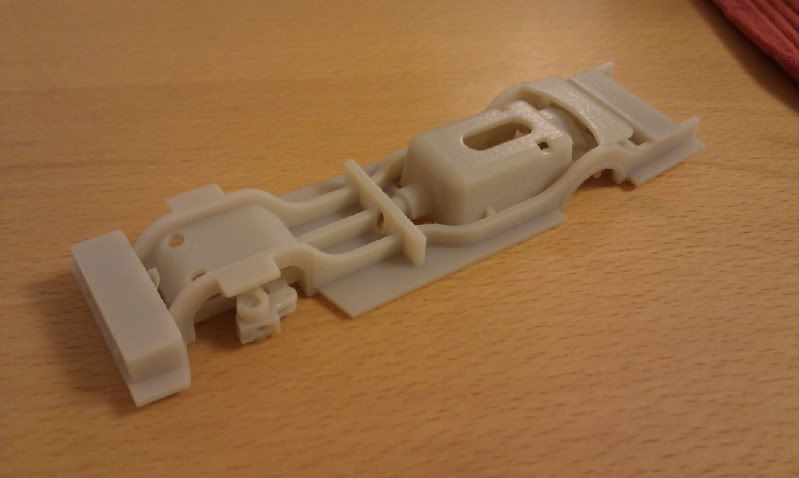

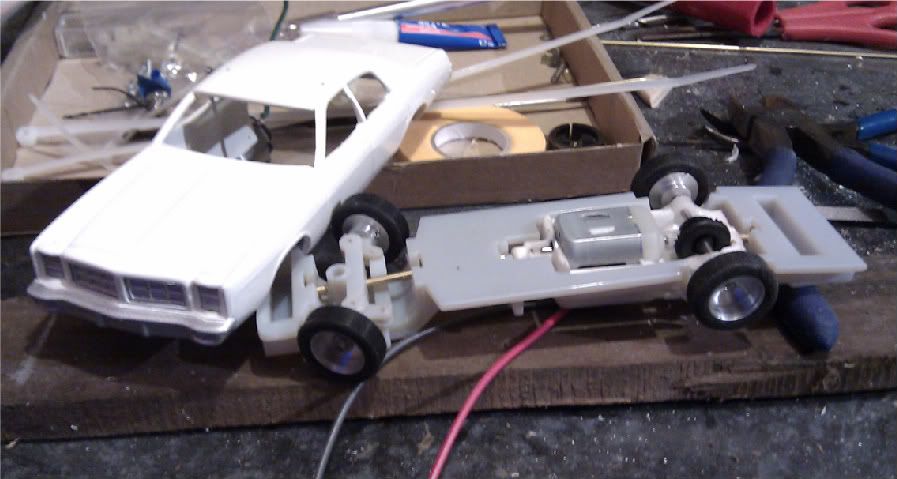

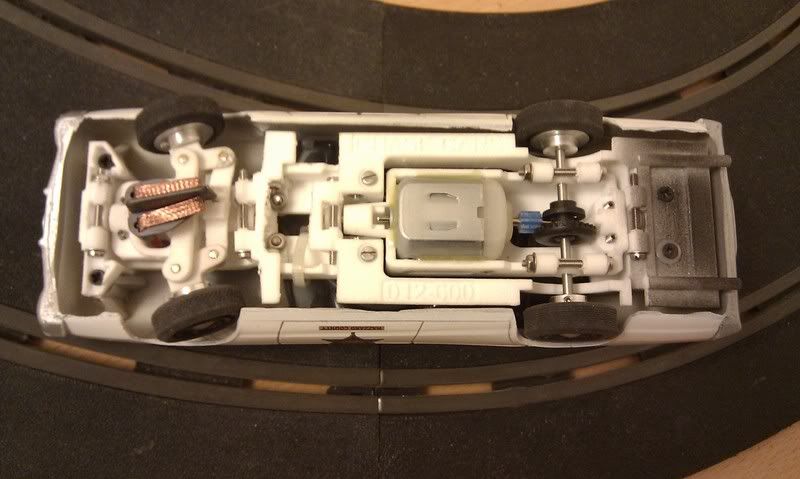

Let's get going with the design proper. I can do the chassis and body but I'll reuse a motor, rear axle and perhaps a guide blade. That means they should be the first things to model up and everything else will fit around it. To hell with that – I want to get going with the body!

I use Solid Edge almost every day, it's pretty rubbish but at least I can use it at lunchtimes. For 12 years before I used ProEngineer which was much more powerful, if I had a copy I'd much prefer to model things using that, but you use the tools you have around you. First tool is some graph paper.

I went to http://www.the-blueprints.com/ and found a 1977 Dodge Monaco, but beware when using these sites because the plan view doesn't always line up with the side view. How I laughed when I found that out

Using my friendly copy of PaintShop Pro, I resized the picture so it printed out 2:1, then I transferred it onto graph paper (see how high-tech and modern this is?). Then I could get the outline shape measured with more accuracy, and I could sketch it in Solid Edge.

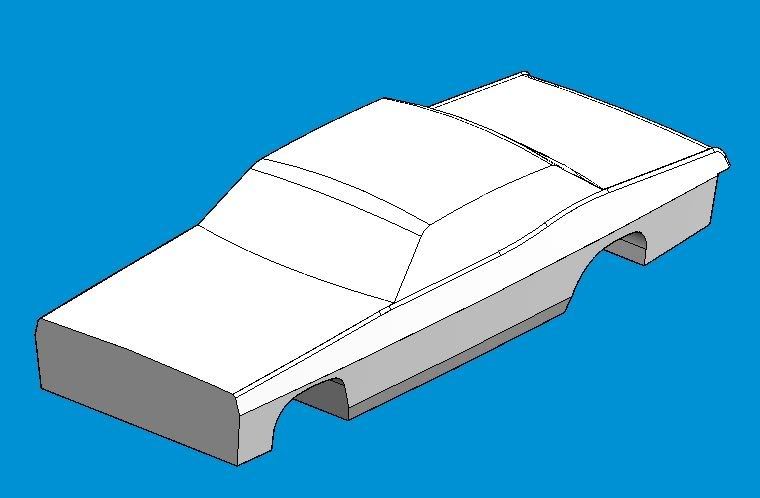

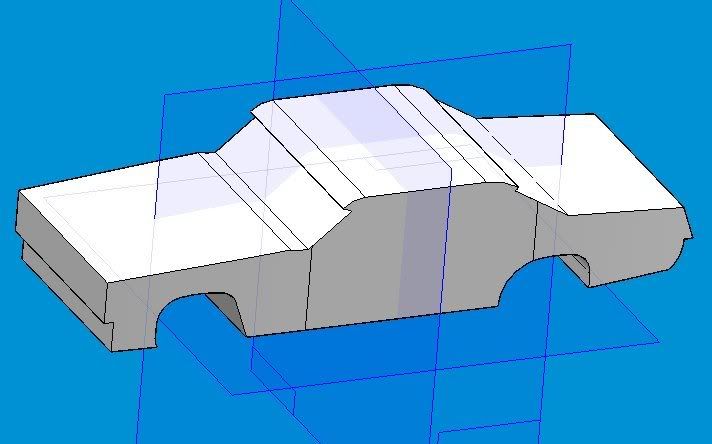

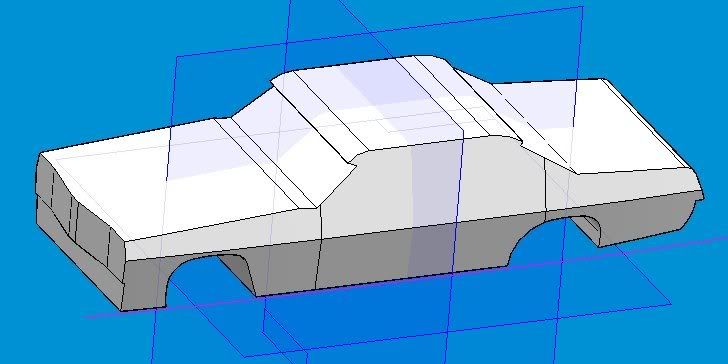

I started by doing a plan view, because the car is tapered front and back, then I sketched the side profile.

I put some shape to the sides

Then made it hollow (shelled), and put a few more features on

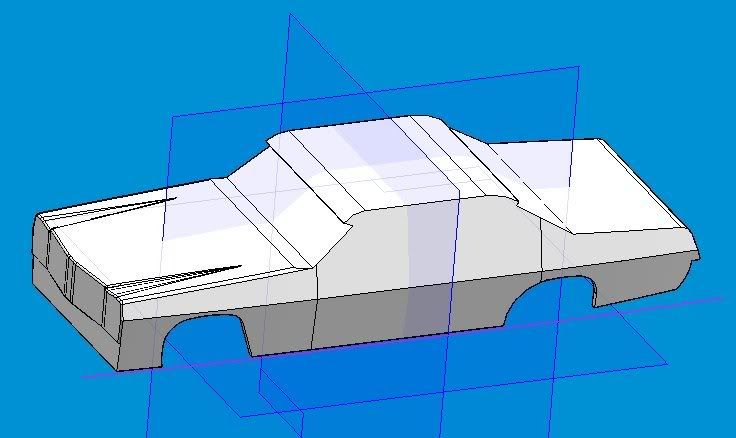

Verdict? Looks awful!

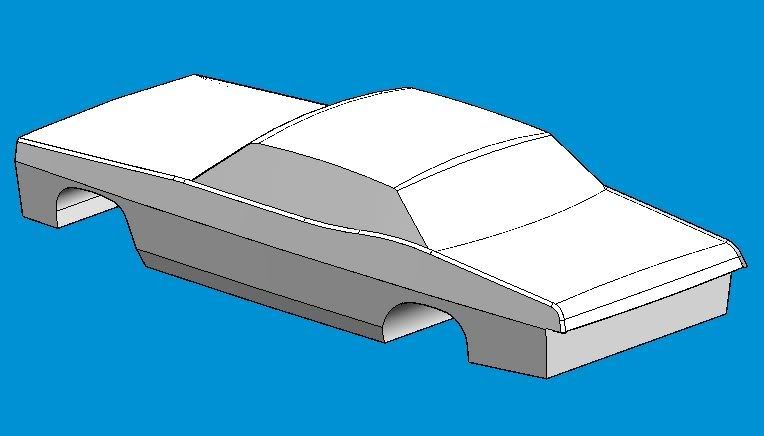

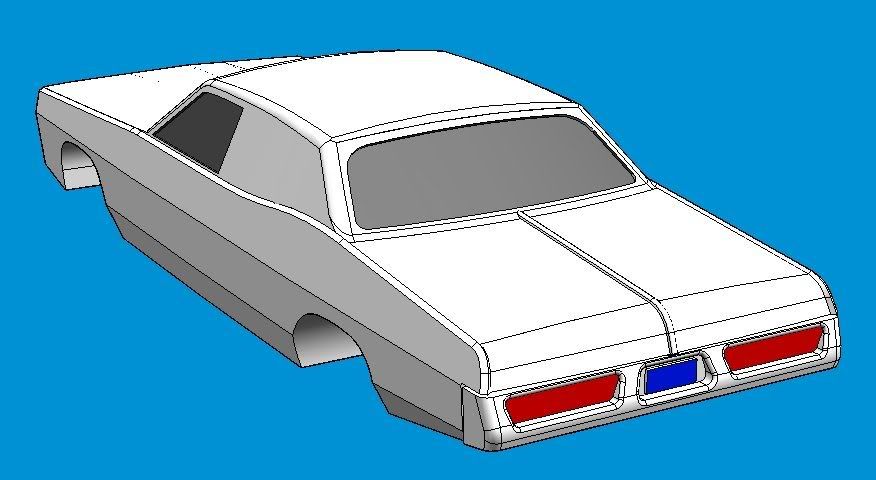

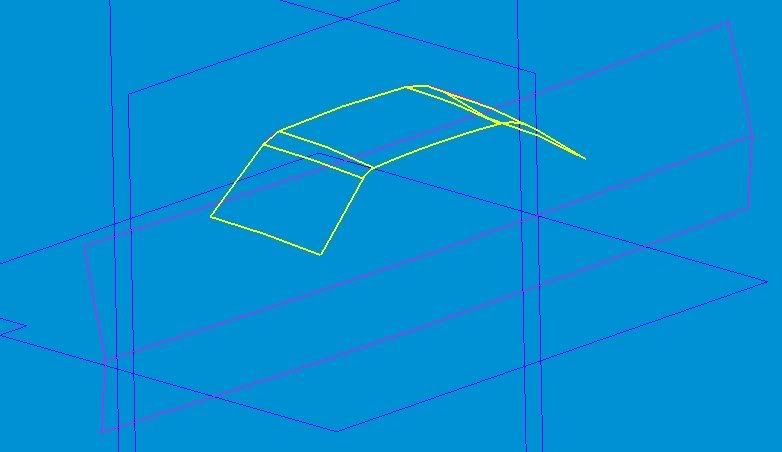

I tried a few different methods, but the place to start seems to be the front and rear screens, then the roof. The rest is comparatively simple. The screens are bounded by 3D curves, so it's time to get started with Solid Edge's surfacing capabilities which are quite limited.

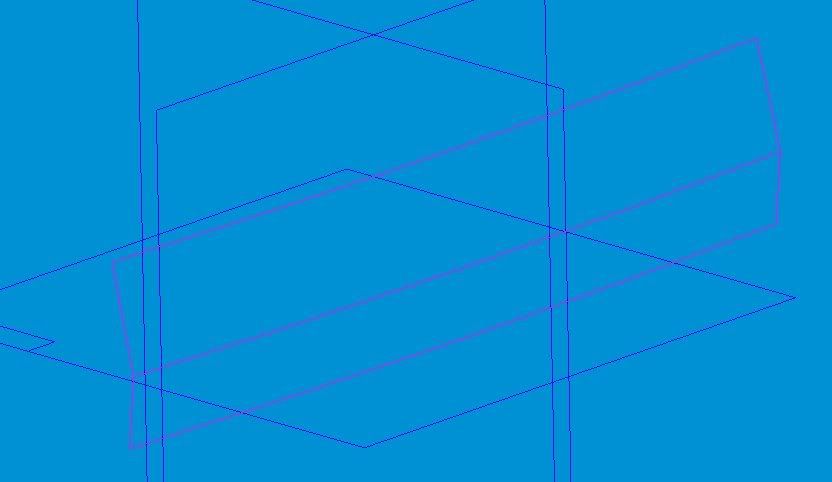

Let's start with a trajectory which is curved in plan view, and the side profile of the car (waistline above the wheelarches) in its path

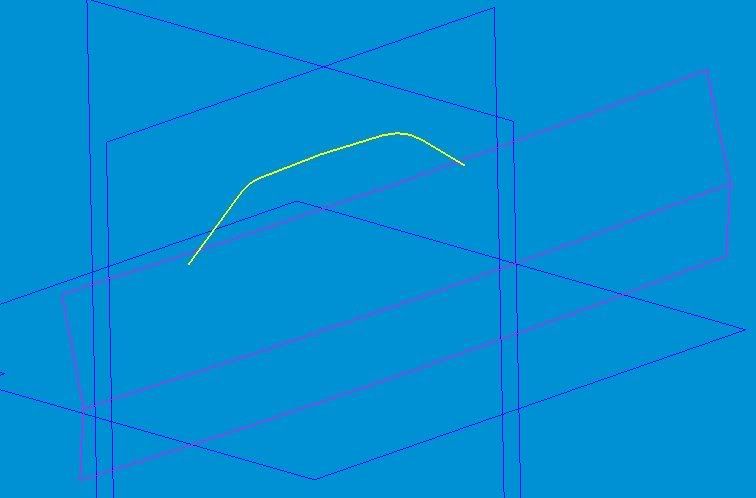

Now we'll put the roof in

Now extrude the roof out to the side

This isn't going anywhere... it still looks rubbish.

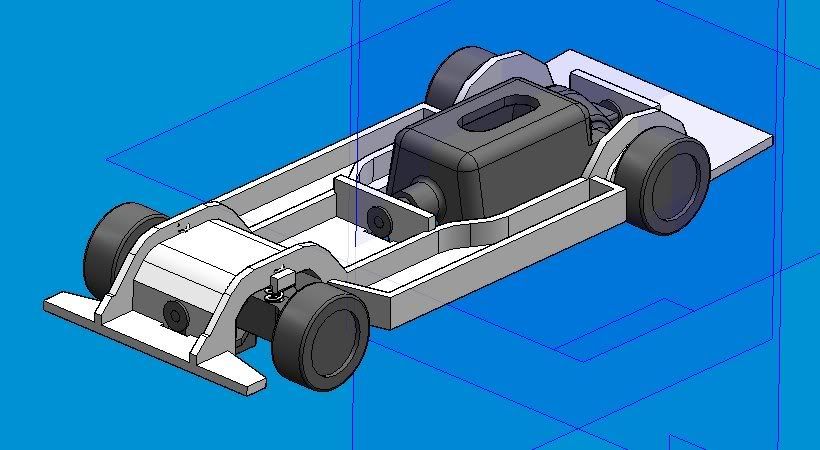

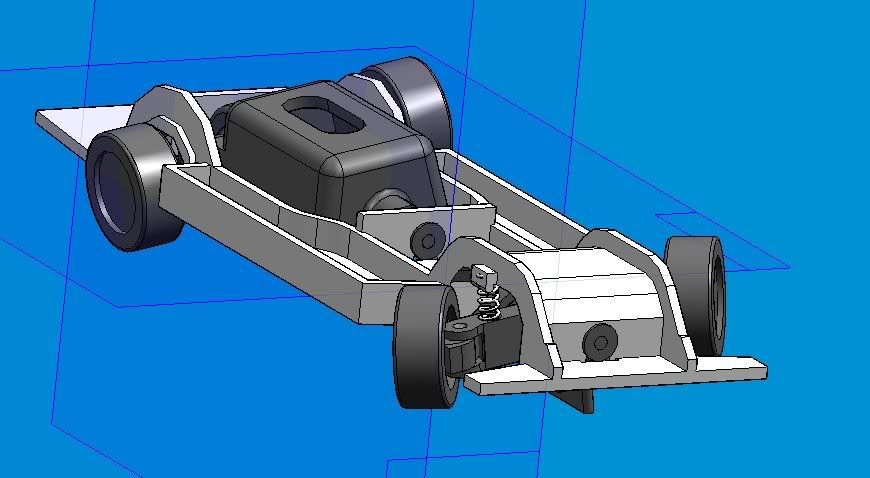

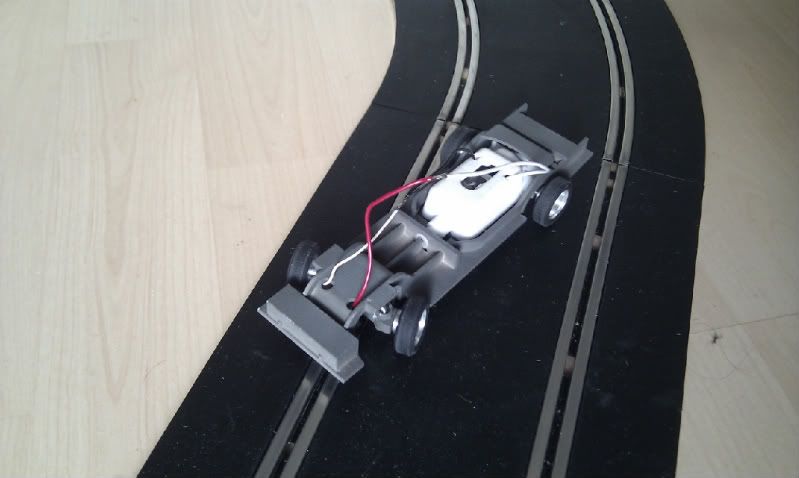

Shall we see where the chassis bits go?