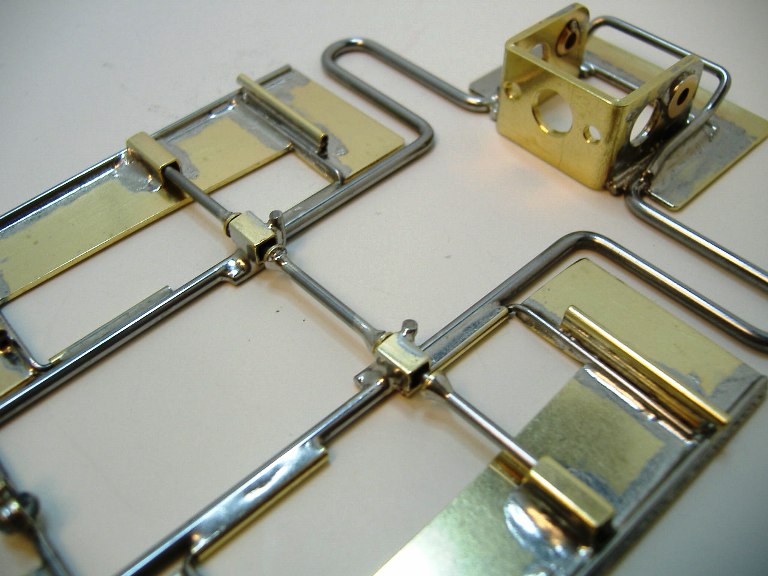

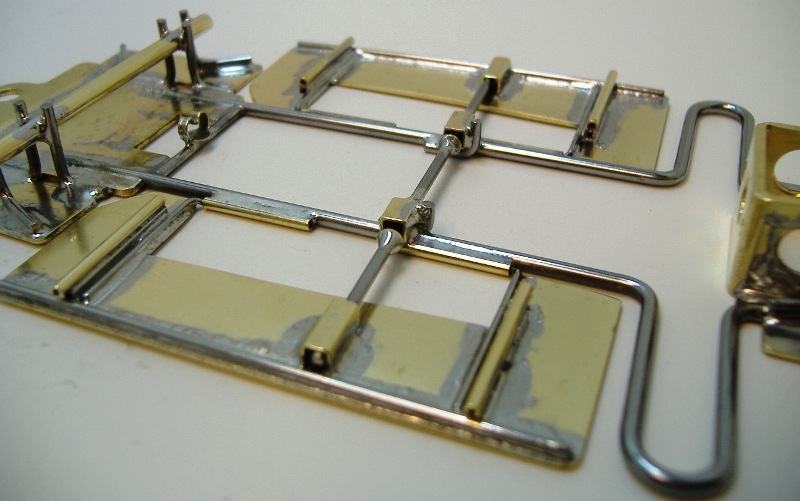

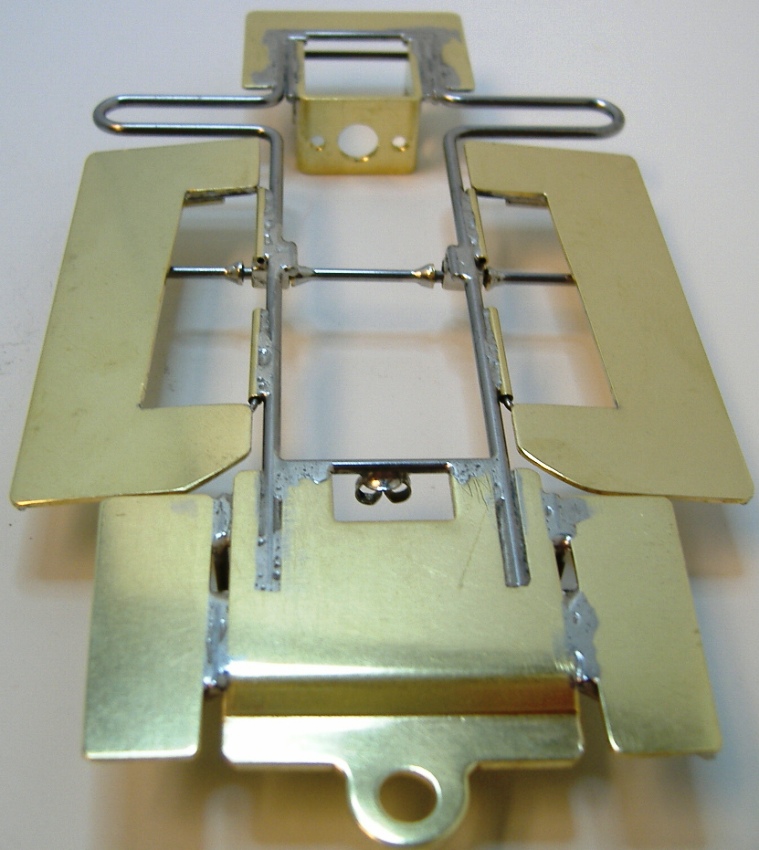

Now if the maker's of the .050 brackets out there would counter bore the screw holes say .015" then at least my complaint's would be resolved.

Hi Rick, Yea. I hear what your saying about the motor screws. Too each his own. From my personal experience the Parma screws stripped the motor can sooner then a machine screw. Also,If it helps or Not? maybe somone else knows.

Jay Kisling was bombasting on this subject at North-South (hey, if we can eat "verb food" like Wraps or Stir-Fry, I figure I got the right to do "adjective actions!")--he believes the self-tapping screws distort the can face and might lead to binding in the can bushing.

If that's so, it don't speak so highly of the integrity of the face, the way I look at it. There're two things going on there--presuming a flat face on both can and bracket (and, don't ever just take these for granted), you're still getting

one sliver edge of thread engaging the thickness of the can flange, one-half turn of the thread max. That & the center boss holding the motor in place--sounds risky, but some of us do it all the time. (an M2 screw, on the other hand, gives you just under two full threads engagement.)

But, after Jay said this, I got to thinking about it. --& I've been leaning more toward using mach. screws to set in place while I'm fitting everything up, and then soldering.

After Rick M. said the thing about counterboring, I priced small c'bores today--found something I could press into service for ~$15, but I'd like a special one with tighter clearances...and with something this small, often operating in interrupted cuts close to the ears of the bracket, your risk of breakage goes way up; and that gets expensive. The manufacturers aren't just gonna give that away, and I wonder where the added expense for this little luxury becomes the deal-breaker.

Another reason to think hard about M2 x M4 screws.

Duffy