Today is a couple of photos to make your builds easier and some more pluses for the jig:

Just for demonstartion purposes, the first photo is to show you how to take advantage the jig gives you, with the wheelbase adjustment holes running the entire length of the jig, they are not only there for building 32nd scale and 43rd scale chassis but you have 1/16" changes for any and all of the needs you have to putting in cross wire and hinge tubes and keep them perfectly perpendicular to your main rails. The adjustment on this feature is once again, almost infinite on positioning. And if you want to rebuild or check some prebuilt chassis in need of repairs. You have the latitude to find positive stops.

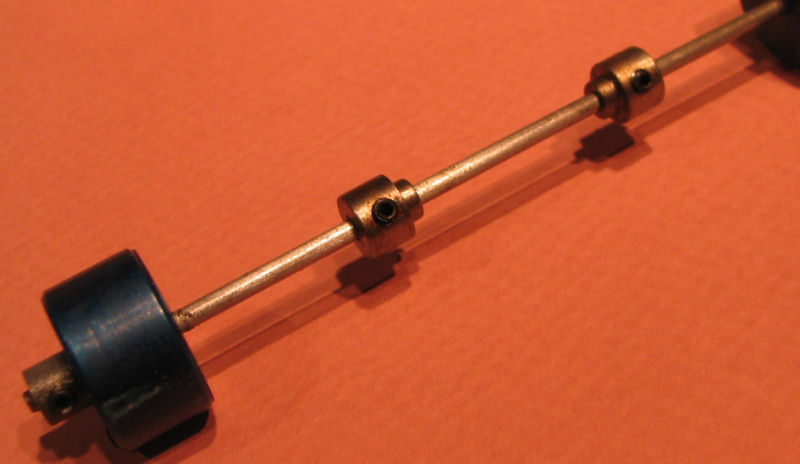

This next gadget is something that is very easy to fabricate and makes pin tube, any size easy to install and perfect on the main rails. You will need to make a left hand and right hand version, as you will see when building some chassis.

You have all seen the gurus of chassis building make their hinge wires and put that little offset in the wire so it lies flat on the pan. This new way of mounting the hinge tubes is quicker and exact every time. Now if about a gram of weight being up .032 from the block bothers your Center of Gravity thinkg, then by all mean, do the tiny offset and just skip this tip.

Take two piece of brass scraps, the thickness of your chassis plate or pan you are going to use. Then take a piece of music wire the correct size to slip inside of the hinge tube, bend an "L" bend in the wire. It doesn't have to be a perfect 90 degrees, just close. I am using .032 scraps and a piece of .062 that fits inside a piece of .093 brass tube.

This is what you should have now, just make sure the bent piano wire lays flat on both pieces of scrap. This is what you should end up with. Solder the brass "L" on to the one piece of brass scarp.

You now have a hinge jig, to attach the tube to the main rail of your chassis. I have the piece of .093 tube on the wire, in the picture. This will allow you to place the hinge tube at the exact height of the pan and other than a 90 degree bend, no other bdens are required for a perfect flat hinge. This trick can be used with any jig or building method, it's not exclusive to my jig.

Here is the part that is exclusing to the R-Geo jig, we once again have all those 1/8" pins along the jig edges, you can now position a wire across these pins, alligator clip it to the pin and then slide your hinge tube gainst the cross wire. Making the pins tubes right and left perfectly aligned wiht on another. No eyecrometer( lol Brain) is required here, it is all positive stop.

This has two pictures, the first to show the hinge tube against the main rail and the second is a reference pic to demonstrate the cross wire for a tube stop.

When soldering the hinge tube to the main rail, I prefer the "Jairus" method. What that is, coat the piano wire well with magic marker and the solder will not wick in and stick the wire to the hinge tube. When you solder the hinge on, heat in the center with your iron and you can view the solder wetting out along the pin, when it is very close to the end of the tube, remove the iron and it stops immediately. You can touch and go if you want it further out on the tube.

Next item is the "Duffy Pinner" brought to us from the lovable Duffy, of course.

Duffy and went a few rounds on this one, I said you only need one side,he insisted that they were needed a pair. He won.

These little gadgets are an optional item that slide over two of the pins along the edge. They can also be moved around anywhere you prefer. ( rememebr the pins change in 1/16" moves) They make it possible to have the same exact pin tube location on any build you create. You are also not limited on pin tube height, in any way. Just drop 1/8" axle shims on the pins and then install the pinners and make them the perfect height you want. Some like to use the Parma or JK wire clips on their builds and with having a dozen choices on each pinner, about any mount spread can be met and repeated.

Many will use a full width piece of 1/16" tube side to side, but if you are using precut hinge tubes, you can just use the pin tubes and a piece of .031 wire to span left and right and keep them straight and aligned.

These could also be used to locate your hinge wires perfectly side to side.

More to follow........stay tuned