I then progressed to a couple of scallops to remove some high weight but still leave enough material in the bend area to be robust and still not rquire any extra bracing. Weight now about 8 grams.

Still many carve up the my brackets and want to save more weight? MInd you I have to work inside the paramters set down by my bending die, so I have to be aware of that. Some don't like the blunt edges etc.

Ok a new generation of my bracket must be born. Today I looked as some blanks and started a R&D project to remove a little more weight and still keep the integrity of the piece and not require any extra bracing. It must also still work with the backatcha piece and still use my punch and die set.

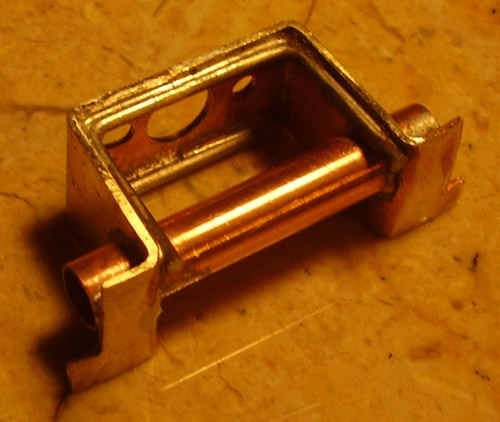

SO here is the latest evolution of the R-Geo bracket*. This is probably not the final version but closer to what some of the carvers are doing now. It's down to 6.2 grams true weight.

Now my discussion part:

Do you prefer a light bracket like the Dubro, for example, and lots of bracing or one that is thicker material and does not require bracing to provide integrity?

How rigid does the motor bracket have to be? IYO

Have yo ever weighed the bare bracket and then weighed it again after the bracing is installed to see exactly how much weight the bracing has added? How much?

DO you prefer the 7/32" tube to hold your oilites/bearings more than a direct fit and why?

* This is not for sale yet and when they are avilable, I will post in Parts Counter with the final version. Lastly, the oilite holes will now be done differently to be much more accurately located and will be avialable hypoid and straight...........