I got an email this morning that I would like to share with you all:

Hi Rick,

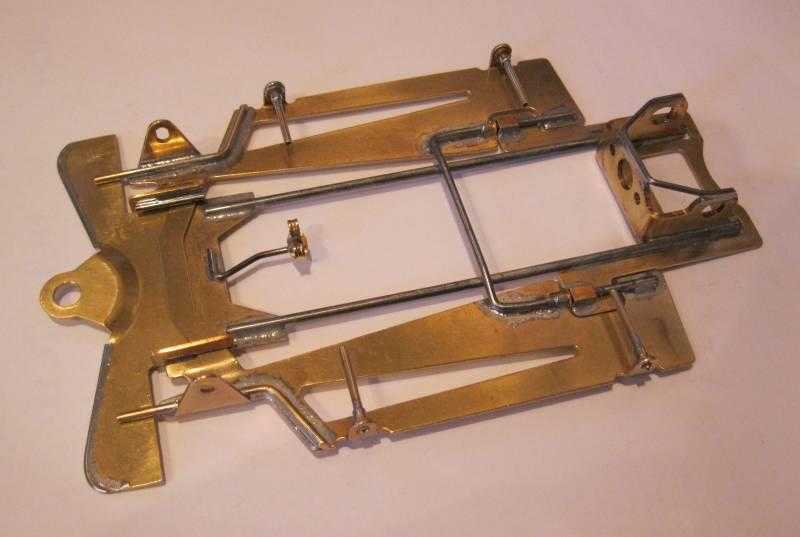

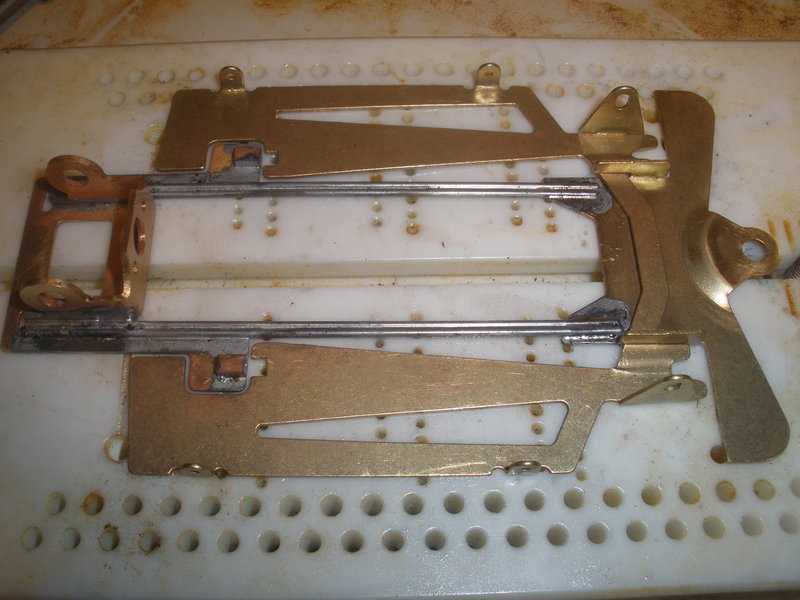

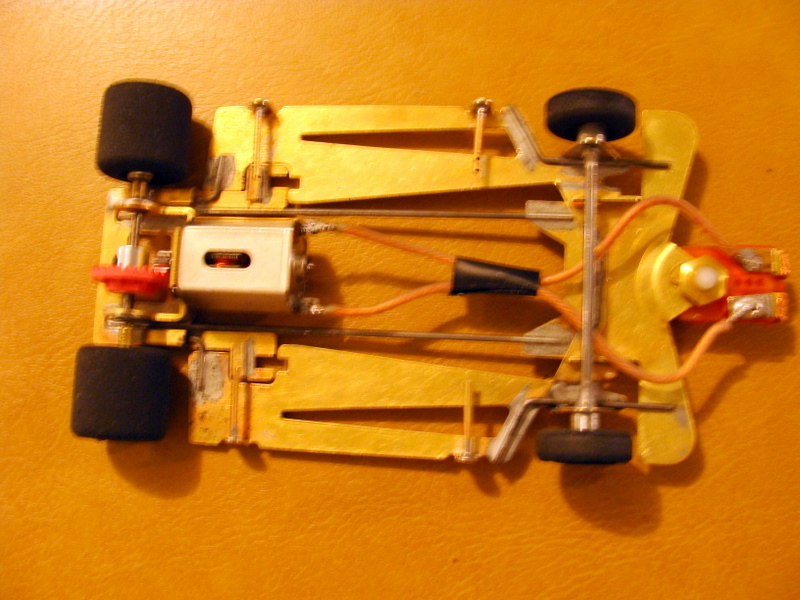

I built my first DragonSlayer last week and tested on Saturday.

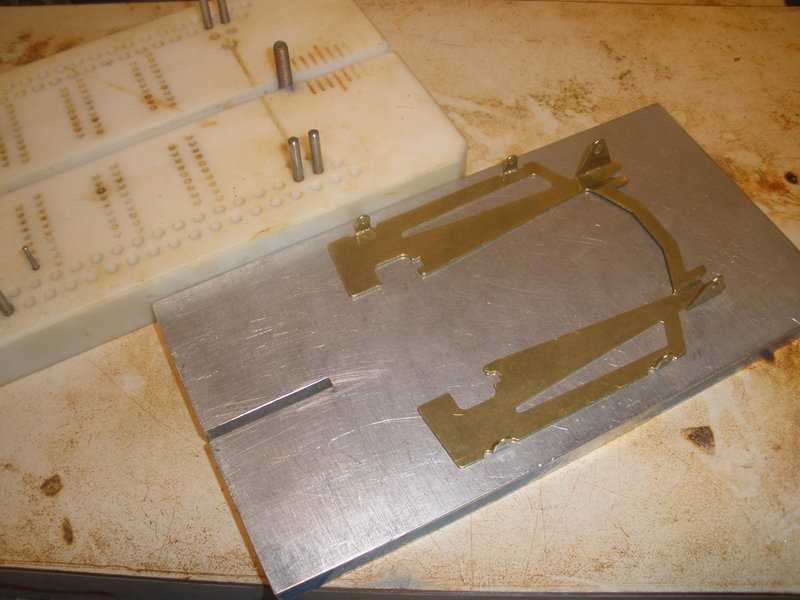

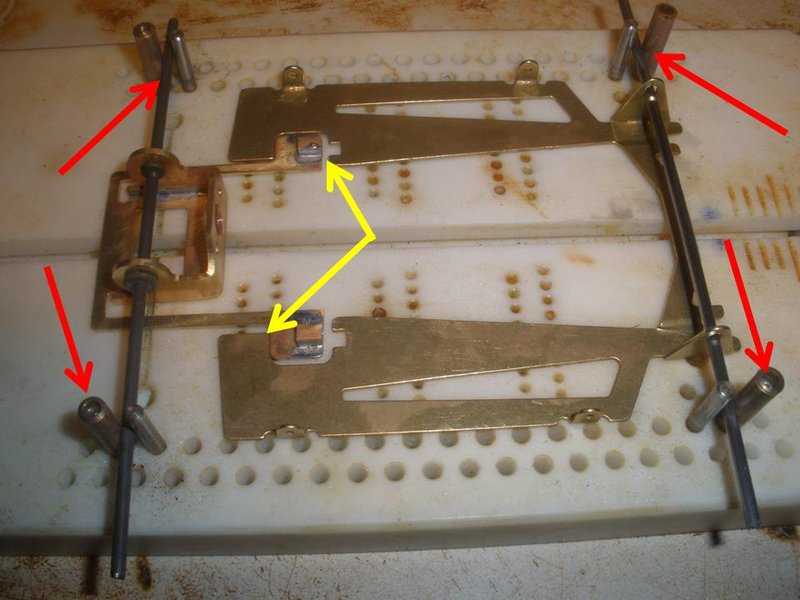

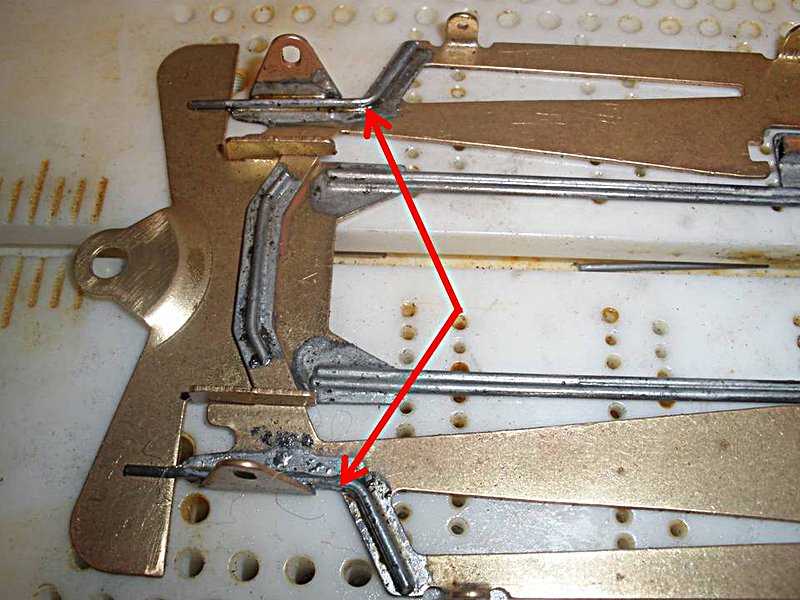

I followed your advice and did a standard build as per Mopar Rob’s on SlotBlog.

I’m very impressed, The new car was quicker than my previous best CanAm car.

I’ve built 6 different design chassis up to now and none of them equal the DragonSlayer!

We race on a 220 Kingleman Our rules are pretty much IRRA except we run a Plafit Cheetah 2 motor only.

A competitive lap time here is 5.8, there are three of us that race in the 5.6/5.7 region with a best I have seen of high 5.4’s.

My cars have been doing 5.5’s at best and only once have I ever done a high 5.4.

Within 10 laps of running the DragonSlayer I was reeling off mid 5.4’s with track conditions not as good as on a race night.

My good Buddy (name removed) is currently building the second car, I’m sure he’ll be very happy as well.

I will let you know how the next race goes on the 19th.

As I have done a standard build and am happy to leave that car alone, I’d like to order some more products from you to do some experimenting.

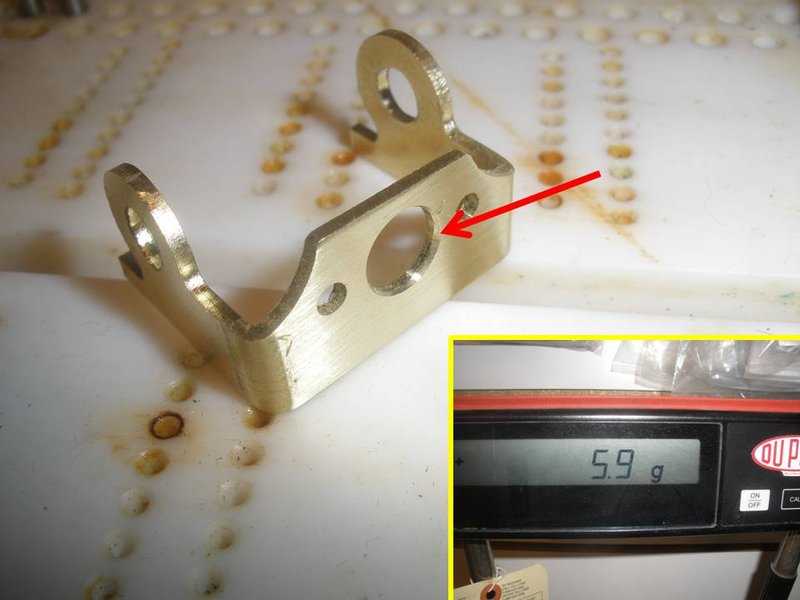

IMO this porject has been a complete success. The Dragon Slayer is easy to build and will make a competitive car. That was the agenda, for average skilled builders to create something that could compete well with the pro builders, at a reasonable price.

The project will continue with updates as I find out areas that need changed or supported as they become raced more and more reports come in.