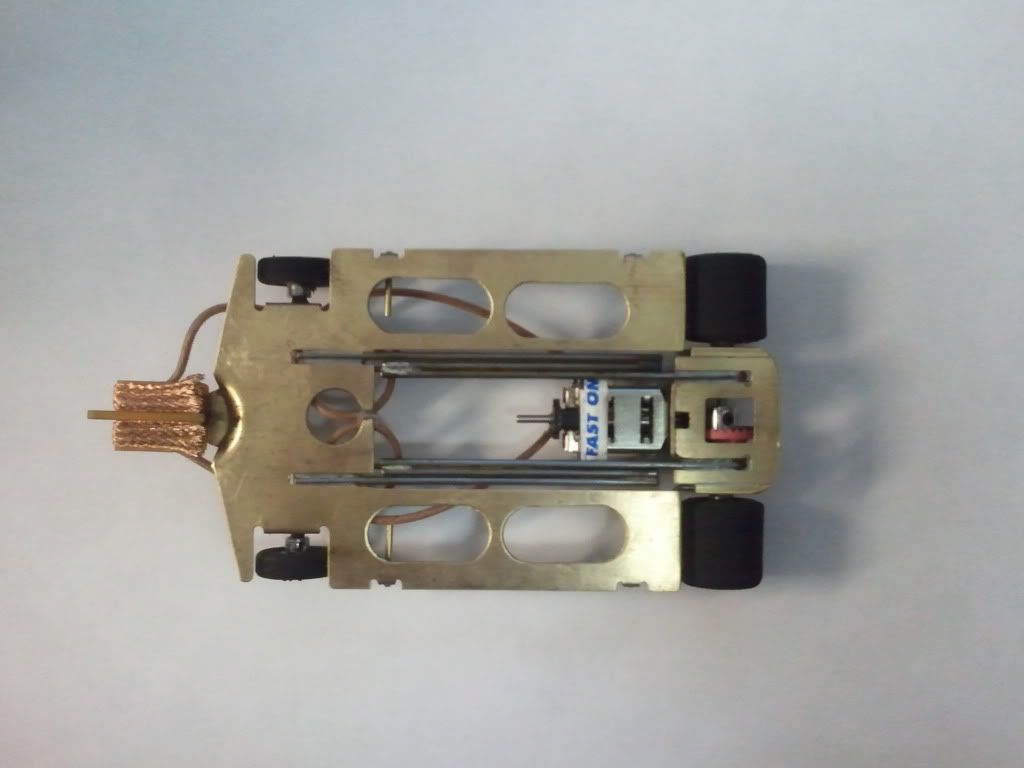

Z-rail chassis

#1

Posted 25 January 2012 - 10:39 AM

#2

Posted 25 January 2012 - 11:51 AM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#3

Posted 25 January 2012 - 11:58 AM

#4

Posted 25 January 2012 - 12:00 PM

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#5

Posted 25 January 2012 - 12:11 PM

#6

Posted 25 January 2012 - 12:12 PM

Wire wrapping would create clearance issues.wire wrapping those joints would go a long way toward strengthening that chassis. Jes saying....

In the case of the car pictured above, the joints are plenty strong.

Look at the length of the down stops soldered on top.

It's a wire triangle stacked like logs.

The only time I saw a Z-rail fail was with a new builder who only had about a 1/4" long solder joint

and didn't have down stops soldered on top because he was using ultra-stiff .078 rails.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#7

Posted 25 January 2012 - 12:21 PM

Thanks for the pics, Mike. Rail diameter?

Pictured are .062".

With using production chassis pieces, .062" works well based on the 2 extra rails per side add up to 1/8" (1/4" total), which then helps the 1" slotting in front match up nicely with the 3/4" bracket in the back.

A local racer, Graham Climpson had a nice finish at our last IRRL race using, IIRC, three .078" rails per side. That was at Mid-America on a super-fast Gerding King.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#8

Posted 25 January 2012 - 12:25 PM

As far as clearance.... soldering the rails together prior to putting them in the jig is a simply solution.

or sanding the bottoms flat will still add a ton of strength from wire wrapping.

But, just my humble observations.

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#9

Posted 25 January 2012 - 12:39 PM

This frame has a lot of sideways flex and on a track where a stiffer car is usually run, I was very surprised on how well this ran. The meachanical grip it generates sure made it jump down the straight but with no lift to deslot. It was also very well planted in the corners and especially flat ones.

Joe "Noose" Neumeister

Sometimes known as a serial despoiler of the clear purity of virgin Lexan bodies. Lexan is my canvas!

Noose Custom Painting - Since 1967

Chairman - IRRA® Body Committee - Roving IRRA® Tech Dude - "EVIL BUCKS Painter"

"Team Evil Bucks" Racer - 2016 Caribbean Retro Overall Champion

The only thing bad about Retro is admitting that you remember doing it originally.

#10

Posted 25 January 2012 - 12:42 PM

Heed Mike Swiss' words - fairly sure he's the father of the Z rail.

I've run quite a few and at the R4/4 I clobbered an errant car with my F1 in practice - tore the front axle loose but the rail portion was fine.

1/8/??-1/11/22

Requiescat in Pace

#11

Posted 25 January 2012 - 12:43 PM

If you sand your rails and use good flux, they are plenty strong enough, especially with that third wire on top.

At last years R4 race I got "ridered" into the "90" full speed from the exit of the "finger" without a solder joint failure.

The original Z-rail Retro car was an F1 that was raced by a pretty inexperienced driver. Along with a few trips over my bank, he also put the car into the metal conduit that houses my power drop to the power supplies in the infield.

Again no rail or chassis failures.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#12

Posted 25 January 2012 - 12:49 PM

There is as much holding the rails together as there would be on a standard two-rail chassis.

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#13

Posted 25 January 2012 - 01:35 PM

I'm working one on right now, but of course it has my intrepretations added. Mine will be raced on a flat track mostly.

Tom Hansen

Our Gang Racing Team

Cukras Enterprises

Team Camen

Chassis By Hansen

I race and shop at Pacific Slot Car Raceway

#14

Posted 25 January 2012 - 02:48 PM

Here's a link http://www.all-spec....CFUcCQAod5T678g

Or just Google it

11/4/49-1/23/15

Requiescat in Pace

#15

Posted 25 January 2012 - 03:44 PM

In the case of the car pictured above, the joints are plenty strong.

Look at the length of the down stops soldered on top.

It's a wire triangle stacked like logs.

That's very true. I would say it's twice as strong. I use to brace joints on wire wing car chassis' by soldering a small piece of wire on top of a joint. It was very effective.

???-2/31/23

Requiescat in Pace

#16

Posted 25 January 2012 - 05:06 PM

11/4/49-1/23/15

Requiescat in Pace

#17

Posted 25 January 2012 - 06:31 PM

First the short .078 wire car

and the long .078 wire car.

I had to add up-stops on both car to run on the Mid America King track, both cars were picking up track dirt on the front Z rail. The short car ran very well at Mid America, even with my lack of experience on the track it was very fast.

Graham

Graham Climpson

Chicago, IL

#18

Posted 25 January 2012 - 07:49 PM

There's times I have trouble telling what's going on with a chassis without holding it in my hands. Here's a simple explanation of a Z-rail: The inside rail is soldered solid to either the motor bracket or the front pan/axle; the outside rail is soldered to whichever of the two that the inside rail is NOT soldered to. So, you have two rails soldered solid at oppposite ends of the chassis. Now, you put a rail IN BETWEEN the inside and outside rails and solder the ends of the middle rail to the UNSOLDERED end of each of those other rails.

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#19

Posted 25 January 2012 - 08:31 PM

Phil, essentially I am doing the same thing with the up/down stops

Ray, I figured that out when I read your first thread about Z rails. Looking at the pics, I thought to myself, "Those joints ain't breakin'."

???-2/31/23

Requiescat in Pace

#20

Posted 25 January 2012 - 09:42 PM

I am not a doctor, but I played one as a child with the girl next door.

#21

Posted 25 January 2012 - 09:58 PM

3i. Wire or tubing rails must connect the front

and rear sections of the chassis. Using metal

strip for this purpose is not permitted. A rail is

defined as that which connects the motor

bracket to the front of the chassis.

The front is connected to the back by wire rails.

This style of car has raced at the last 2 Sano's and the last R4.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#22

Posted 25 January 2012 - 10:14 PM

???-2/31/23

Requiescat in Pace

#23

Posted 25 January 2012 - 10:24 PM

Here's the rule:

3i. Wire or tubing rails must connect the front

and rear sections of the chassis. Using metal

strip for this purpose is not permitted. A rail is

defined as that which connects the motor

bracket to the front of the chassis.

The front is connected to the back by wire rails.

This style of car has raced at the last 2 Sano's and the last R4.

Yes, but the rail from the motor bracket DOES NOT connect to the nose piece, it connects to another rail.

As the rule is written, these chassis are illegal IMHO.

And isn't this getting awful close to the dreaded "Center Hinge" chassis design?

I am not a doctor, but I played one as a child with the girl next door.

#24

Posted 25 January 2012 - 10:25 PM

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

#25

Posted 25 January 2012 - 10:32 PM

Nope, it is still rails. Nothing says it has to be one rail.

Joe "Noose" Neumeister

Sometimes known as a serial despoiler of the clear purity of virgin Lexan bodies. Lexan is my canvas!

Noose Custom Painting - Since 1967

Chairman - IRRA® Body Committee - Roving IRRA® Tech Dude - "EVIL BUCKS Painter"

"Team Evil Bucks" Racer - 2016 Caribbean Retro Overall Champion

The only thing bad about Retro is admitting that you remember doing it originally.