Blast relay

#1

Posted 18 March 2012 - 09:44 PM

#2

Posted 19 March 2012 - 07:36 AM

Chris

#3

Posted 19 March 2012 - 08:11 AM

#4

Posted 19 March 2012 - 11:48 AM

#5

Posted 19 March 2012 - 11:59 AM

#6

Posted 19 March 2012 - 12:11 PM

In the lower portion of the frame, there are holes to allow you to attach a standard size Micro switch with an activation lever . The microswitch is connected to the lower set of screw holes in the frame. The lever(typically 3-4 inches long)cut and bent to activate when the trigger was in the full power position. Then either car power (black) or ground(red) wire was connected to one side of the Normally Open contacts. The other side went to the coil of the relay. The other side of the relay was connected to either red or black wire that was not connected to the micro switch. The the track power (Red) and Ground(Red) wires were connected to the relay.

This connection prevents the relay to be energized when the trigger is not pushed, but bypasses the resistor area of the controller under full power.

You may have to removed a little of the handle in front of the activator arm to allow it to both turn on and off the micro switch.

Chris

#7

Posted 19 March 2012 - 12:26 PM

In the first one there's 30a microswitch on the right for WOT, and a 10a microswitch on the left for brakes.

In the second one, you may get some ideas how to install your hinge. I just used a small brass furniture hinge, then installed a peice of brass stock on the back-side of the trigger. The spring was installed between the hinge and the piece of brass. Smooth, light, consistant pressure. I cant remember if I cut down a spring bought from a hardware store or made one from scratch.

#8

Posted 19 March 2012 - 01:32 PM

#9

Posted 19 March 2012 - 03:01 PM

Putting a hinge on the trigger is not an easy task. If you are wanting a smoother feel to the trigger, here are a few easier things to do:

I have taken the resistor out of the controller and "faced" it on a steel file. Hold it down and slowly file the bands until you see a change on all the bands. Typically, the dead band could be protruding out just a bit. The dead band and both end bands are pretty thick, so you can take some off of them before you get to the mid bands.

If you can find a new trigger button, you can round the outer edge and let it float inside the hole in the trigger. You can solder a wire to the button (not real easy) and then solder it to the copper part of the trigger. That way it won't fall out.

When the button is in the hole in the copper, take a piece of 220-400 sandpaper between the button and the resistor, grit side out. Pull the trigger for a minute holding down the sandpaper on the resistor. Then you should have a surface that will seat to the resistor.

Just a few things I used to do to Turbo Controllers to make the trigger smooth.

Chris

#10

Posted 19 March 2012 - 04:05 PM

#11

Posted 19 March 2012 - 08:11 PM

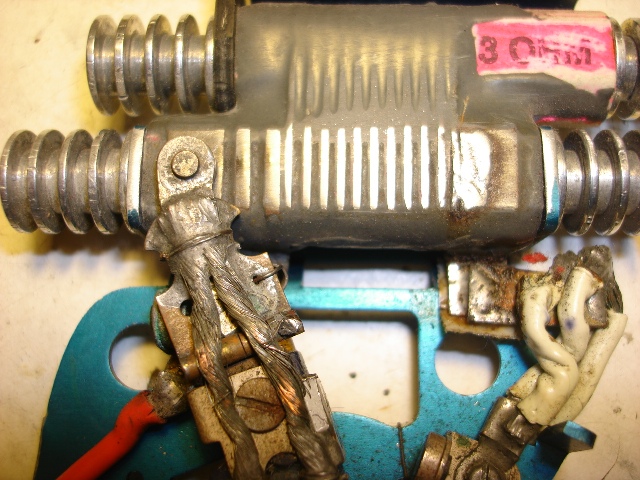

Here's a resistor that started as a "blown" stock parma unit. I removed much of the insulation, soldered the burnt last band, and coated the whole thing with JB weld. This also give you a better view of the cabinet hinge. Wasnt that difficult with the use of the piece of brass stock, installed on the back of the trigger (see previous photo). One spring worked great.

This control didnt have a blast relay, so I went overboard with the shunt wire, in an attempt to get max current flow.

#12

Posted 19 March 2012 - 10:15 PM

#13

Posted 20 March 2012 - 08:28 PM

Chris had a Great idea with the Music box hinge, but here's the original Fleming Hinge and I can Attest to how smooth and nice it can make a controller, I'm in the process of building a new external Resistor Controller that will Have a Fleming Hinge, roll out for Drag Racing, and a last Relay

–Von Dutch

Rickard Johnston

All images © Rickard5

#14

Posted 21 March 2012 - 08:12 AM

My philosophy is that instead of putting a bandaid on it, prevent the cause. The reason you want a hinge is because of the roughness of the resistor you are swiping. Then make the resistor smooth and the cause of the problem is greatly decreased. It is also easier and quicker to do than putting a hinge in the controller. Also no more moving parts to break.

#15

Posted 23 March 2012 - 10:38 PM

#16

Posted 27 March 2012 - 02:53 AM

Cry like a baby, drive like a girl, walk like a man.

Give me enough rope and I'll build a fast car... or hang myself?

#17

Posted 28 March 2012 - 08:16 AM