Track braid questions

#1

Posted 09 September 2012 - 06:02 PM

1. I have always used the "original" Weldwood contact cement, which has become much more expensive over the years. This time I went to Lowes and found all of the larger size cans are "gel" formula. I have never worked with this and an not interested in paying $20 for a failed experiment. Have people used this and which is better?

2. I saw pictures of a re-braiding job at a commercial raceway on Slotblog. They were using some sort of over-sized syringe type of applicator. It looked and sounded way easier than the brush I currently use. Where can I find such an applicator?

3. In the same article, they were scraping old contact cement using screwdrivers. I have a router bit and was planning to re-route the area, going a fraction lower than my current "flush" braid height. Why would I not do this?

3. When I braided by track the first time, I ran the braid continuously. I then expanded it, and had to add some connector sections. Since I sometimes need to replace just a section of braid, I thought it might be nice to automatically put in these "taps" every few feet. With an 82' track, I was thinking that 4-6 might be good. Any advice?

Thanks, guys,

Ken Bryan

Spokane, WA

#2

Posted 09 September 2012 - 07:53 PM

JB

Requiescat in Pace

#3

Posted 09 September 2012 - 08:34 PM

Have others used the tape to rebraid?

"Racing makes heroin addiction look like a vague wish for something salty" - Peter Egan

#4

Posted 09 September 2012 - 08:39 PM

Mack Johnson

'86 Mustang footbraker

6.435 @ 104 MPH

NC Slot Car Tracks - Past and Present

#5

Posted 09 September 2012 - 09:09 PM

#6

Posted 09 September 2012 - 09:26 PM

The best glue application "tool" we found was a Glu-Bot. You can find them at a woodworking supply store or through Amazon. Perfect for putting down a nice bead of glue.

Rollin Isbell

#7

Posted 09 September 2012 - 09:36 PM

I need to re-braid a portion of my track right now, and am thinking of redoing the whole thing this winter. I have some questions:

2. I saw pictures of a re-braiding job at a commercial raceway on Slotblog. They were using some sort of over-sized syringe type of applicator. It looked and sounded way easier than the brush I currently use. Where can I find such an applicator?

3. In the same article, they were scraping old contact cement using screwdrivers. I have a router bit and was planning to re-route the area, going a fraction lower than my current "flush" braid height. Why would I not do this?

Ken,

The re-braiding job you saw on Slotblog was the one we did at my raceway, 'Slots of Fun', in Abbeville, SC. The "over-sized syringe" you mention is called a "Glu-Bot". The 16 oz. size costs ~$6.00 and you can buy several accessory tips for your needs. It works great! You can order one on-line at Amazon.com/hardware and then search for glu-bot.

As for the screwdriver method of removing the old braid glue, do it only as a last resort. The only reason we used a screwdriver was because I did not have the proper router bit for the job. By all means, re-route the area using a router but be careful not to shave off too much of the braid recess.

We use the Original Weldwood Contact Cement.

Hope this helps.

V/R,

Don

Don Berni

#8

Posted 09 September 2012 - 10:43 PM

"If you have integrity, nothing else matters, and if you do not have integrity, nothing else matters."

Robert Mueller, special counsel (2013)

"... because people have got to know whether or not their president is a crook."

Richard M .Nixon, Nov 17, 1973

"Fool me once, same on... shame on you. Fool me... you can't get fooled again."

George W. Bush

#9

Posted 09 September 2012 - 11:48 PM

First, regarding the tape. I have used it, and if my entire track were MDF, that is all I would use. But the original surface was plywood, built in the 80s. When I redid the straightaway about 3 years ago I converted it to MDF. One of the best slot car decisions I ever made. I routed it, painted it, applied the tape, then braid. Was awesome to use. Granted it is a straightaway, but not an issue in 3 years.

Then I decided to use the tape for repair on the plywood portion of the track. It almost never worked, because I never had pristine surfaces. I never took the braid groove down to bare wood, and there was always a little oil or contact cement residue. And the surface was too rough. So I went back to contact cement for the plywood portions. I have tried both contact cement and the 3M stuff (aka Gorilla Snot). What I found was that the 3M stuff was easier to apply out of the tube, and it seemed to hold better. But it tended to build up more, raising the level of the braid after repairs. Since I started with braid that was flush, this eventually became a problem and I went back to contact cement. If I had more braid recess it would work better.

My goal is to replace other sections of the track over time with MDF. I will use tape then. But for now I will stick with the contact cement. Since no one recommends the gel, I will stick with the original and try the Glu-Bot.

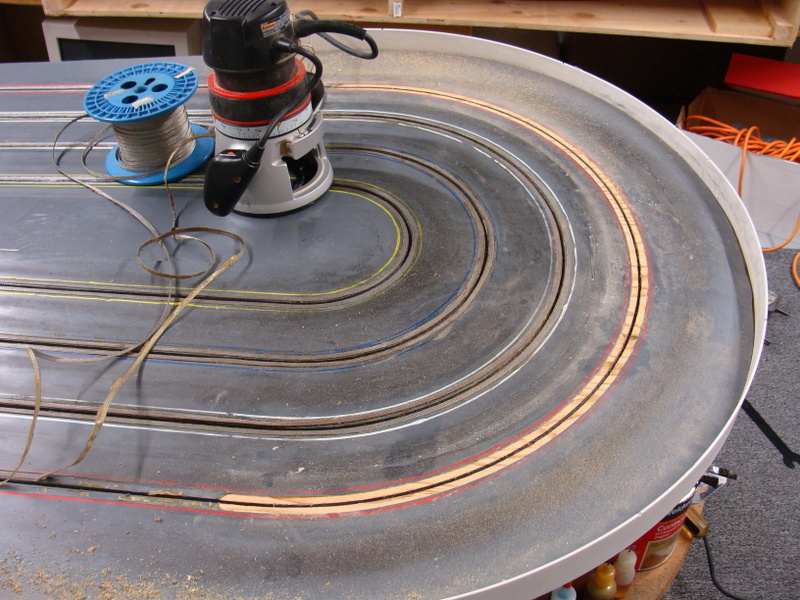

Here is my little repair so far. First, you can see just how bad this one section of braid got to be:

So I pulled up both sides and routed the whole corner down to bare wood. With the special bit, this took less than 5 minutes.

I am painting the routed section before I glue, and put taps at both ends to re-braid both sides of the lane.

Will show the whole thing when done. Seriously planning to do the whole (60') plywood section this winter.

Ken

#10

Posted 10 September 2012 - 04:25 PM

#11

Posted 10 September 2012 - 07:45 PM

PRECISION SLOT CARS - BUILT TO WIN

Check out my track at Precision Slot Cars

#12

Eve Neilson

Eve Neilson

Posted 15 September 2012 - 04:53 PM

We used the 3m tape on all 4 of our tracks and have no problems with it so far (the oldest been 3 years). I changed 1 of my corners and pulled some of the braid off. I had to get a knife between the braid and wood otherwise it pulled off the wood (painted) or tore the braid. Very easy to use.If you are going to re-route the braid recess, and if you are going to paint that recess, then I suggest you look into the 3M product that Slot Car Corner sells http://www.slotcarco...-Thick-p34.html It looks like a double sided tape, but it is really a means to apply a 1/4" wide strip of glue. I used it on my 5th track build and it's a lot easier to use than glue and there is no mess to clean up. Then only thing is the the braid recess has to be painted - it won't stick to bare MDF.

JB

#13

Posted 15 September 2012 - 06:16 PM

We used the 3m tape on all 4 of our tracks and have no problems with it so far (the oldest been 3 years). I changed 1 of my corners and pulled some of the braid off. I had to get a knife between the braid and wood otherwise it pulled off the wood (painted) or tore the braid. Very easy to use.

I have found it easier to use a hot soldering iron to heat the braid/glue before removing the braid. The 3M product works great and doen't come loose after cleaning with naptha.

Requiescat in Pace