New JK chassis performance

#1

Posted 18 September 2012 - 02:19 PM

Now that there are some built out there, anyone got any information positive or negative?

#2

Posted 18 September 2012 - 02:26 PM

Joe "Noose" Neumeister

Sometimes known as a serial despoiler of the clear purity of virgin Lexan bodies. Lexan is my canvas!

Noose Custom Painting - Since 1967

Chairman - IRRA® Body Committee - Roving IRRA® Tech Dude - "EVIL BUCKS Painter"

"Team Evil Bucks" Racer - 2016 Caribbean Retro Overall Champion

The only thing bad about Retro is admitting that you remember doing it originally.

#3

Posted 18 September 2012 - 06:18 PM

Sunday I did a little testing on the JK, built for super spec. at the Sano, seamed to have a lot of bite, I am thinking it would make a good flat track car. Testing was at Boogie Speedway 155 ft. Hill Climb. First off I tried the car with Koford soft wonder tires at .830. It felt good but got loose when pushed hard didn't deslot but the back of the car would start to come around. I then put on a pair of Koford Treated tires new out of the bottle again around .830 Dia. the car was to stuck with those and would lift out of the slot when pushed. Koford Soft Soft wonder tires would have probably been just right but I didn't have any with me.

The Dragon Slayer III is in the chassis fixture now hope to test my Sixteen rail version tomorrow. In its stock form the Slayer III is also a simple build. Next is an.078 rail X25R. More testing will tell the story on both these new Chassis kis

Regards,

Greg V.P.

12/4/49-4/17/24

Requiescat in Pace

#4

Posted 19 September 2012 - 09:30 PM

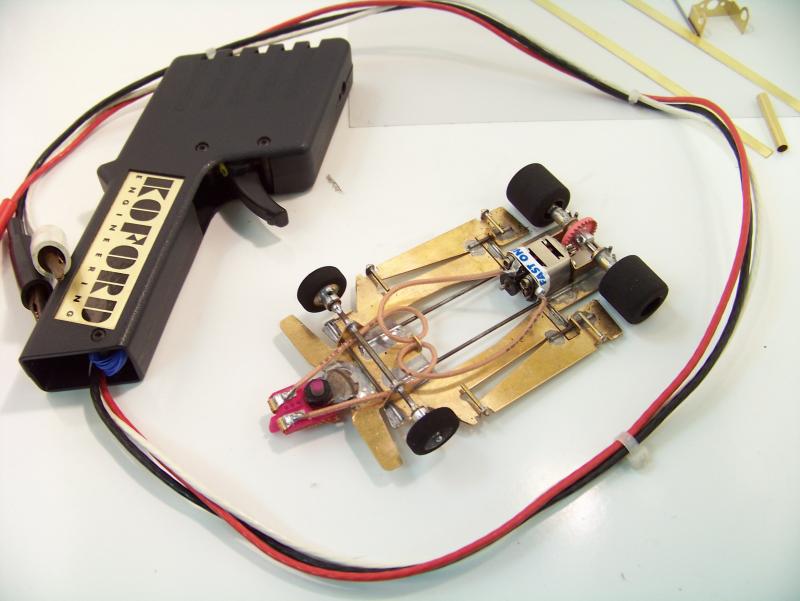

The .062" rail, X25R, seems to be an excellent flat track car.

I ran a real nice 5.25 on my flat track, with the car pictured, built by Lee Verdich.

Even more impressive considering it was done at a very light 106G+, (usually 118-125G is the ticket),

and using the "high tech" Koford rental controller pictured.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#5

Posted 20 September 2012 - 08:25 PM

GRRR 2016 GT Coupe and Stock Car Champion and Overall Champion

My Series Spring 2016 4" NASCAR, JK LMP State Champion, and Endurance State Champion

My Series 2015 4" NASCAR, GTP and Endurance State Champion

GRRR 2015 4 1/2" and F1 Champion

GRRR 2013 & 2014 Evil Flexi Champion

1968 Cleveland Car Model Series race winner - Tom Thumb Raceway, North Royalton, Ohio

1968 Hinsdale ARCO Amateur runner-up

1967 Parma Raceway Indy 500 Champion

#6

Posted 05 October 2012 - 09:54 AM

I had thought that I would have to add weights but in practice it ran like it was on rails and was putting up the best lap time.

Right from the start the car went straight to the front and was running very fast and handeling like a dream. After the first four heats I had a 14 lap lead. Then I had a little trouble, one of the motor screws came loose and it slowed down some. I found what was wrong and got back some of the speed (hurt the crown gear). Finished the race with I think a three lap lead. Next race the motor will also have some solder holding it in.

There was only one other D3X25R chassis on the track and he was having motor troubles.

Over all the chassis was very good in the high bank turns and was very good in the flat turns, may be too good. When on the inside lane of the flat turn it was almost too tight. I had to play with the controler to get it to come ut of the corner without a deslot.

We will see how things go the second time we race. If this chassis still works better than the others, or how many D3X25R are built and race.

#7

Posted 25 October 2012 - 11:46 AM

The second kit was stiffer and it made the chassis loose in the flat turn. But it was a bit faster through the high bank turn.

#8

Posted 25 October 2012 - 12:46 PM

Thanks much for taking the time to post your mods and observations with the chassis.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#9

Posted 25 October 2012 - 01:16 PM

Mike Katz

Scratchbuilts forever!!

#10

Posted 25 October 2012 - 01:28 PM

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#11

Posted 03 November 2012 - 05:13 PM

- Ralph Thorne and John Dickinson like this

8/16/55-9/16/17

Requiescat in Pace

#12

Posted 06 November 2012 - 06:54 PM

http://slotblog.net/...race-2-results/

Josh

#13

Posted 06 November 2012 - 08:17 PM

Your performance at Tom Thumb with the X25R inspired Bud Bartos to finally build his.

In our conversation last night about other chassis parts, he went out of his way to mention he built it and how impressed he was

with it's performance on both the Rt.93 King and the Washington Flat Track.

He did comment on he felt at 111G's at Washington, he might of been on the light side, especially after picking up the

top finishing cars of the Lauterbach's .

He also used the term (or one like it) of being a basic build, but he did add that it had, IIRC, 4-.047" rails per side.

Maybe he'll spot this post and put up a pic of his car.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#14

Posted 12 January 2013 - 10:13 AM

And I also saw where James Merriman has put bite bars on the JK X25 builds that where shown at the Handicapped Race.

#15

Posted 13 January 2013 - 03:04 PM

We have some newer racers here in CO. One exceptionally talented driver, Trevor, bought one of the new JK kits and we made an evening commitment last Thursday to build it up. I brought my Precision retro chassis fixture and offered to help build it.

The pieces feel odd, lighter than they look. We measured the thickness of the pans and it confused me as they were .029 by my calipers, an odd size (expecting .03125), I measured the rear motor bracket over and over and it seemed to have the right dimensions. I haven't installed axle tubes in a couple of years so that was new again.

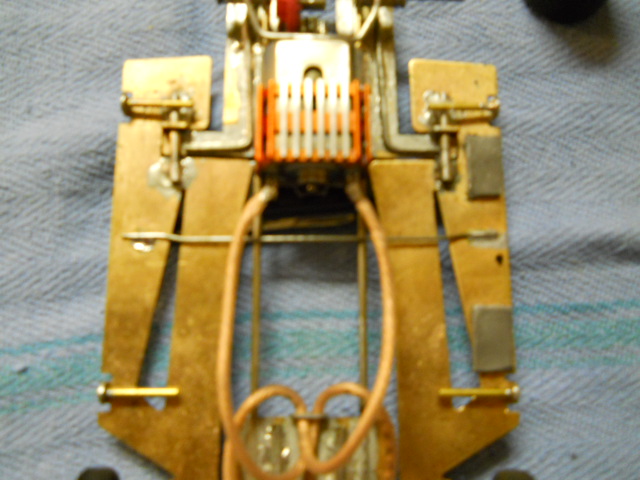

We made it with two straight rails of .0625 piano wire, which seem to be what the pre-cut slots in the front pan and the remaining gap in the rear pans (after soldering in the rear motor bracket) were designed for. If one uses the gaps in the chassis components and evens them out (fore-aft), it pretty much dictates the wheelbase and the guide tongue to the front axle dictates the guide lead so there is no guess work.

We decided to solder the front axle to the front pan uprights and decided to let the bat pans "hang" on the stationary front axle through its front axle uprights, choosing not to cut them off.

The fixture tends to suck too much heat when getting that "good flow" of a proper solder joint, so I refluxed everything and put it on my hardwood solder board to finish it. It was still absolutely flat and straight and square after a final inspection on the fixture.

A single piece of .047 wire was soldered to the forward / lateral portion of the rear pan and to the aft portion of the rear pan through the bent-up tab in the bat pan to the portion limiting the lateral motion of the bat pans to the 3.125 maximum chassis width but allowing inward motion and upward.

Another short piece of .047 wire was soldered into the corner of the front pan front axle uprights going forward to the "wings" of the front pan and soldered there. This allows a bit of upward motion to the aft of the bat pans. The bat pans must twist this piece of wire to go "out of plane" and still rely on the front axle upright as a downstop.

Very simple. There must be hundreds of ways to attach the bat pans - this was just a quick way to get it on the track. Our very careful and deliberate build took less than 3 hours.

The entire car was only 104 grams with the body, RTR and it was a rocket on our 155' Hillclimb track, were very few Can Am cars under 115 grams ever work well. It was "planted" flat everywhere and really snapped around the bank.

We will, likely, do some axle tube reinforcement wires and add a steel guide tongue reinforcement later but it served very well in his first RMRRA race yesterday, getting a very competitive third place in his first race with his own car (I hate loaning him mine, he beats me with them!).

I wholeheartedly recommend this chassis to new retro racers that have some basic soldering skills. Ask for an experienced guy to show you how to prep the wire, how to apply the flux and show how to get a proper "hot" solder joint and loan you their fixture. I think Trevor gets a lot more satisfaction getting a third place with his own car than beating all of us with a borrowed car...

This is a car you can experiment with (bat pan attachment, lead positioning) because you can always go back to the basic initial build, which is pretty darned quick! Great job Jerry and anyone else who had a hand in designing and/or testing this product! Absolutely a bargain!

Keep it in the slot,

AJ

Sorry about the nerf. "Sorry? Sorry? There's no apologizing in slot car racing!"

Besides, where would I even begin? I should probably start with my wife ...

"I don't often get very many "fast laps" but I very often get many laps quickly." ™

The only thing I know about slot cars is if I had a good time when I leave the building! I can count the times I didn't on one two three hands!

Former Home Track - Slot Car Speedway and Hobbies, Longmont, CO (now at Duffy's Raceway), Noteworthy for the 155' Hillclimb track featuring the THUNDER-DONUT - "Two men enter; one man leaves!"

#16

Posted 27 March 2013 - 07:41 AM

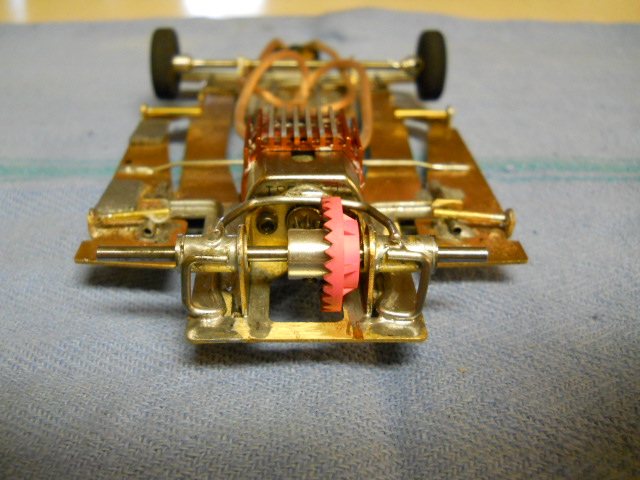

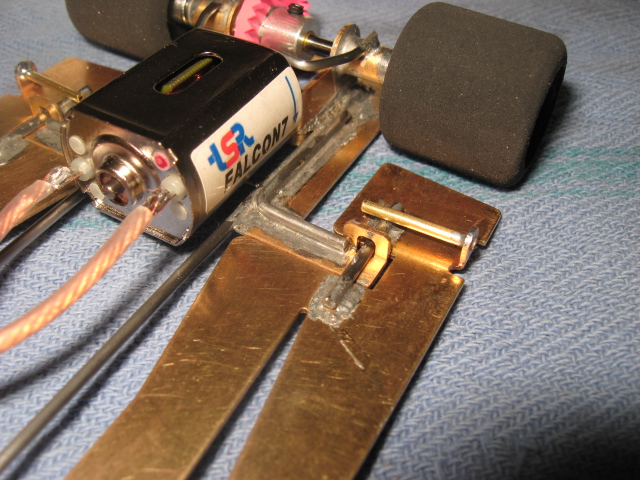

I made a couple of changes to my second X25R, first on the first the axle tubes on the rear where bent from racing and I decided to reinforce the braces on them.

I bent .055" wire in a U shape and ran it down to the back bracket on the chassis.

I then took a .047" wire to make a bite bar for the pans to help limit their movement.

These two changes have made alot of defference, the first race that I ran with these changes saw me improve my lap total by better than 30 laps for the race. Not only that, all the way through the race I was setting lower and lower lap times even on the last heat.

I have to say I have never had this much fun with slotcar racing as I have had building and running my own chassis builds.

RETRO is a blast.

#17

Posted 28 March 2013 - 08:28 AM

Sorry but I had a typeO I had run 3 laps more not 30.

#18

Posted 28 March 2013 - 09:13 AM

Les, nice looking build! Hope you are going to make it to the Music City Retro Shootout in April @ Central TN Raceway in Lavergne TN. Rick

Rick Crutchfield