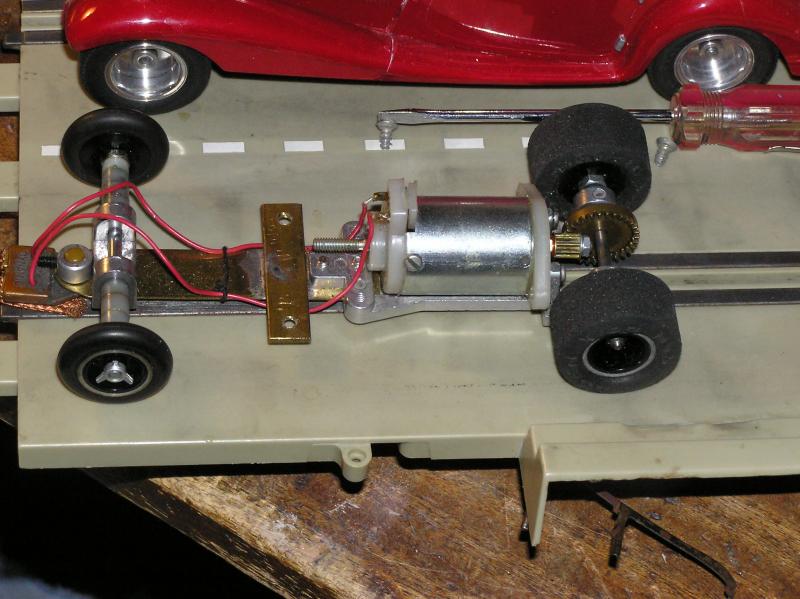

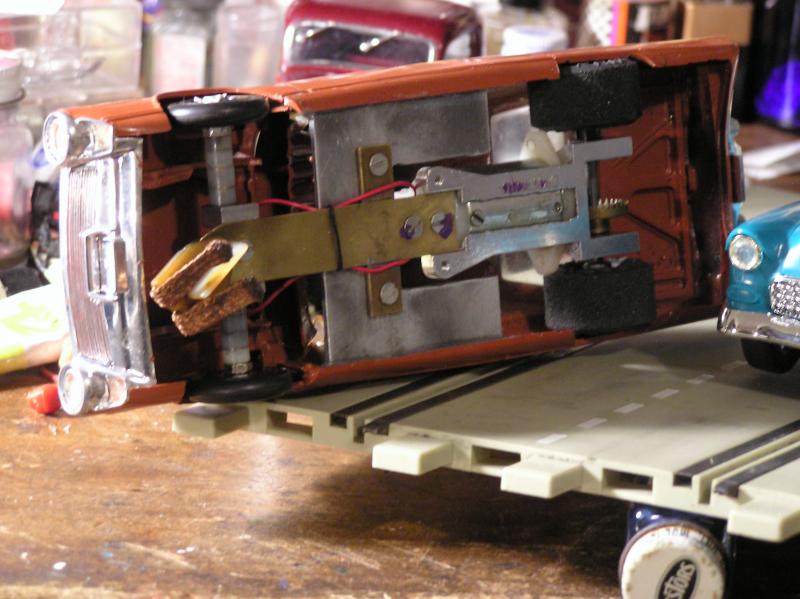

I'm looking for the best # of turns using 28 wire for vintage 16d endbell motors (FT16). I just tried 60 turns of # 30 on a Johnson motor but it doesn't appear to be too earth shattering. I'm using these style motors in the Monogram Stocker chassis, as was used on the Vintage Duesenburg.

The motor is not going to play well with a rewound arm that's fairly hot using the stock magnets. A jump from #30 wire to #28 wire is a big jump with those magnets, and the motor might run warm (ie: HOT) with #28 wire unless you upgrade the magnets. I go with 65 turns of #30, 55 turns of #29 with those magnets and no hotter. The spring tension will make a BIG difference. Using the stock springs will hamper performance, and modern springs (most anyway) should fit the small (FT16D size) motors. New springs will give your motor a nice shot in the arm. If you're going to go with a rewind, a magnet upgrade and new springs will help things a LOT. You may just find that your 60T/30 wind is a lot stronger than you thought. Lastly, if you can't get new magnets, shim the existing magnets as tight as you can without them touching the arm.

***Oh yeah, the stock com will likely be the next weak point if you get the above sorted. They can blow super-easily.

***If you get past all of this, then balance will be the next hurdle. As the arms get faster, imbalance causes greater and greater problems...faster wear on the bushings, arcing at the com (limiting revs and causing extra heat)

I was using a chrome plated can , probably Cox, in a similar Mercedes 540K , until the white (derlin) commutator melted. I stripped it down and found 121 turns of # 34 wire. I found a green com from another arm and again would like to rewind it with #28 , hoping this com is better. It ran super before .

I would again use #30 wire (maybe #29 if you don't care too much about longevity). If you're dead-set on #28 wire, try somewhere around 40 turns, but it's not really a good idea.

I just rebuilt a Champion Orangepicker but upon completion I discovered none of my brush springs will fit over the post protectors so I used an awl and opened up a suitable pair. Question is what can I make brush springs from ? In the past I have used old (steel) guitar strings to make other springs, but most of the brush springs I have seen are a type of copper ?

I use .014"-.015" stainless steel guitar strings and go with either 3 or 4 coils. The old copper springs lose their tension and barely offer enough force to keep the brushes in contact with the com...often greatly limiting revs. The conductivity of the springs isn't really an issue, and most modern springs have been made of steel for a long time already. When you wind them, try and use a mandrel that is slightly smaller in diameter than the spring posts because, as the spring relaxes when you take it off the mandrel, it will slightly increase in diameter. When you cut the springs to length, try and get the short arm of the spring long enough to go fully across the brush hardware without being so long as to "hang up" on the other side.

One more question, I would like to try to remagnetize a round motor made by Wilson's of Cleveland but I am not getting much of a reading using a compass. Anyone have any experiece with these before I go and tear apart a NOS motor ? Here are some photos of the Wilson motor used to power the Chysler Turbine car ( I thought a fitting tribute) Gb

Try asking Rick Thigpen here ("DC65X"). He's got a mambo-sized military-grade zapper and a LOT of familiarity with the vintage motors.

-john