Bill Steube Jr. 4 Rail Sports Car

A re-creation late 1966 chassis by Steve Okeefe

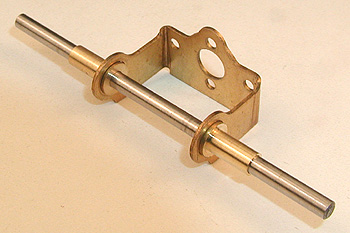

This particular build was copied directly from the original, but because I used a REHCO #3000 motor bracket and tube type rear axle bushings, it is a period-correct re-creation and not a replica.

If you look carefully you might also notice the thick-wall pickup-guide tube. This is a favorite detail of mine; aside from being quite strong, it puts a bit of extra down-force in a spot where it does a lot of good.

Another favorite detail that is near impossible to see is the stainless steel tube drop arm hinge pin. It’s a leftover from the “Stainless Steel Racer” build. The stainless tubing happens to be slightly oversize at .065” diameter. Using it not only removes all the “slop” in the hinge, but also prevents the hinge from seizing up over time due to rust, a real possiblity with piano wire.