Inline Motor Bracket Bracing 1966

From no bracing at all to struts, ellipticals, semicircles,

squares, horseshoes, bumpers and "D" loops

January, 1966: No braces. In keeping with the early 1966 paradigm of ultra-lightweight chassis design, scratch builders at first did not use any motor bracket bracing at all.

Photo right: Mike Morrissey Team Russkit Mclaren Elva; recreation by Rick Thigpen.

February, 1966: Builders had begun using simple strut type braces.

Photo center: Team Russkit "Factory" Chassis.

Photo right: Jim Kirby, 2nd R&C race.

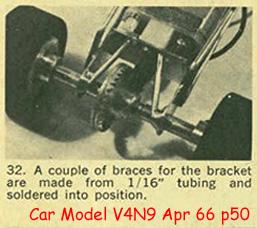

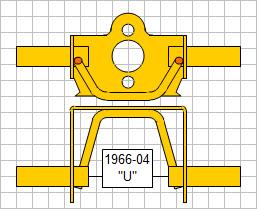

April, 1966: The simpler one piece "U" shaped brace began to appear on racing chassis. In addition to being simpler, and for a tiny penalty in weight, this type brace adds considerably more strength to the bracket than the two piece type it replaces. For its day, a very sophisticated design.

Photo center: John Cukras, 2nd R&C race.

Photo right: Dave Grant, 3rd R&C race.

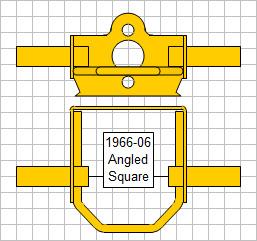

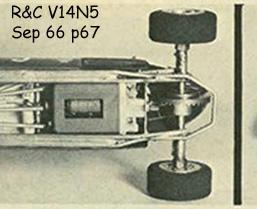

June, 1966: Angled square inside brace. Turning the one piece brace around makes the "U" shaped motor bracket into a box, which provides some protection for the crown gear in crashes and thus contributes to the reliability of the whole car. Although slightly heavier than earlier brace arrangements, by mid 1966 motors scratch built for racing were more powerful, so the penalty of additional weight was more than offset by the added reliability of a bracket brace that doubled as a gear guard.

Photo right: Don Peters, 3rd R&C race.

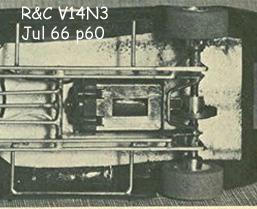

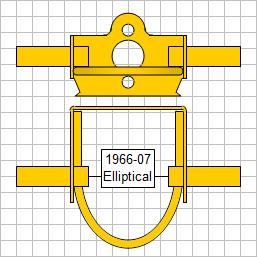

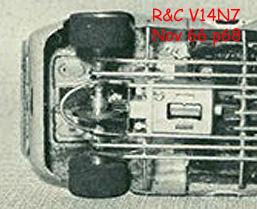

July, 1966: Elliptical inside brace. Always looking for ways to simplify construction, builders soon began to form their brass rod bracket braces with one large bend. The elliptical shape resulted from using a small radius form (or no form at all) to bend the tubing or rod and simply allowing the legs of the brace to assume a naturally widening curvature until they were parallel. Elliptical braces are aesthetically pleasing to the eye, and do a good job of protecting the crown gear in a crash, but from a purely structural standpoint they are a poor design choice because they are not very strong as an actual bracket brace.

Photo right: Mike Morrissey, 4th R&C race.

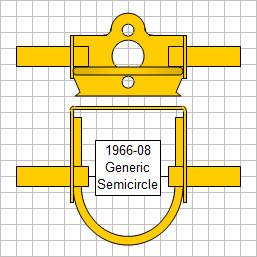

August, 1966: Semicircular inside brace. Improving on workmanship for the single bend brace meant forming it in a constant radius that resulted in a semicircle whose diameter matched the inside dimension of the motor bracket. In actual construction, the well fitted constant radius semicircle was fairly easy to achieve by first getting close, and then simply "tweaking" until everything fit. Of course, the less tweaking the better! This design, although mechanically a bit stronger than the Elliptical brace, still had a tendency to collapse in a hard lateral wall shot to either rear wheel. By September of 1966 this was becoming a real problem because cars were heavier, going considerably faster and hitting the wall considerably harder.

Photo center: Mike Steube, 4th R&C race.

Photo right: John Cukras, 6th R&C race.

August, 1966: Square inside brace. In designing and building racing cars, even 1:24 scale cars, form must inevitably follow function. The function of a brace is to add strength, in this case lateral strength against deforming the bracket in wall shots to the rear wheels, so builders began to use a square brace. In pure form, as shown in the diagram to the left, the sharp bends result in a square brace that provides maximum resistance to lateral bracket deformation in a crash. This brace is about as strong as a single one piece brace can be, tripling the thickness of two of the three sides of the bracket, it has long solder joints and will resist lateral stresses up to the yield strength of the material it is made of, in this case, brass rod.

Photo right: Roger Newell, 4th R&C race.

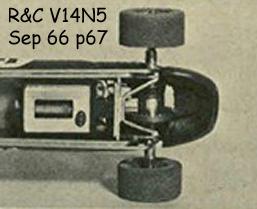

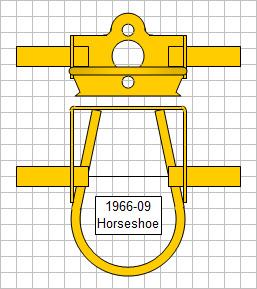

September, 1966: Horeseshoe inside brace. This clever and unusual one-piece brace features a very long semicircular loop with the legs of the brace at angles to the bracket arms, forming secondary triangular braces. It is among the last of the one-piece braces to be found on a pro car.

Photo right: Team Russkit car probably built by Mike Morrissey in mid-late 1966.

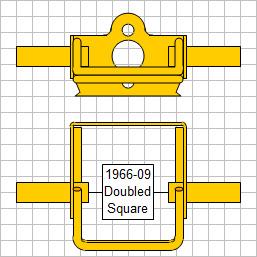

September, 1966: Doubled square inside brace. If one is good, two must be better.

Photo right: John Anderson, 5th R&C race.

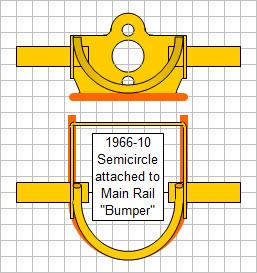

October, 1966: Semicircular inside brace attached to a main rail "bumper". The lower semicircle of brass rod that the bracket brace is attached to is actually a main rail, presumably serving the purpose of a bumper, but does not directly brace the bracket at all.

Photo right: Mike Morrissey, 6th R&C race.

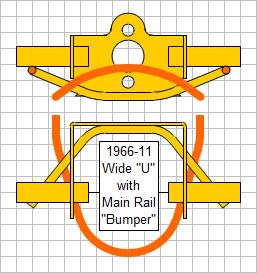

November, 1966: Wide "U" strut brace with main rail "bumper". This unusual Mike Steube arrangement, in which what looks like a semicircular bracket brace is actually a mail rail bumper, a wide "U" shaped strut brace is all that strengthens the motor bracket against crashes.

Photo right: Mike Steube chassis, probably late 1966.

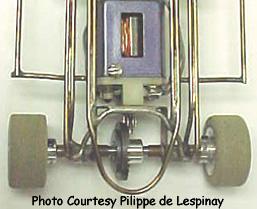

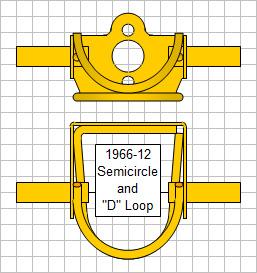

December, 1966: Semicircular inside brace and "D" Loop motor mounting plate brace. Another unusual Mike Steube arrangement that includes a "D" shaped loop of brass rod that serves not only as a motor mount plate brace and a bumper, but also an attachment point for the semicircular motor bracket brace. The serpentine strut braces shown in the photo, but not in the drawing, were added later.

Photo right: Mike Steube chassis, probably late 1966.