Why Motor Bracket Bracing is Necessary

As nearly perfect a solution as it was, the original design of the integrated inline motor bracket, including the Russkit bracket, had fundamental flaws, not the least of which was some inherent structural weakness. To be fair, the structural weakness in this simple design was essentially unavoidable, because it was caused by the design of the motor it was intended to mount!

In the diagram below you can see three holes arranged vertically in the center of the motor mounting plate; one large hole in the center for the motor bearing and two smaller holes for motor mounting screws. You can also see that two of these three holes very nearly cut the bracket in half!

Coupled with the relatively thin material the bracket was made of, the total cross-section through the center of the bracket was small, and therefore structurally weak. Even if the design of the bracket were to include widening the upper narrow area shown by the diagonal red line in the diagram above, the weak spot would simply shift to a location along a vertical line through all three holes, still a total of less than half of the cross-section of the rest of the mounting plate.

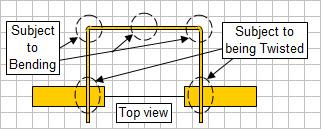

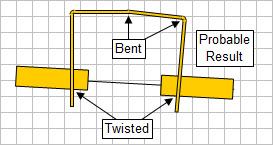

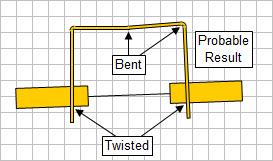

If the bracket was going to be bent in a crash, through the center is one of the most likely spots the bend would occur, as shown in the diagrams below:

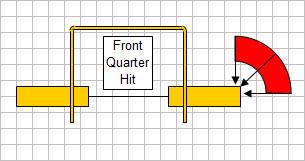

It is an axiom in competitive slot racing that crashes inevitably occur. High speed crashes that involve one of the the rear wheels impacting a solid object, such as a wall or another car, will over stress an un-braced bracket through the axle and cause it to bend at the weakest point. If the crash impacts the wheel from the front around to the side, the bending is likely to be toward the rear:

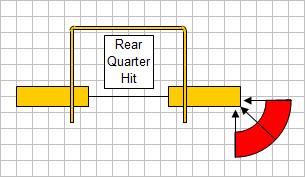

If the impact is from the rear around to the side, which is actually more common, the bending is likely to be toward the front:

Bracing strengthens the bracket against crash impacts and helps prevent damage, and as a general rule-of-thumb, the more bracing the better. Unfortunately, even the best thought-out and constructed bracing does not always work!

As an example of what can happen, here are three photos of a 1967 Mike Steube built three-rail sports car chassis that was involved in what must have been a horrific crash. The chassis suffered a hard impact from the right rear which, despite extensive bracing, warped the motor bracket, broke numerous solder joints and bent all three main rail uprights plus a half rail upright on the right side:

Motor bracket bracing is always necessary, but it should be correct for the overall weight and anticipated speed of the car. When building replicas, recreations or period-correct original designs, the type and style of the bracing should be correct for the time period represented.