A Recreation 1967 Mabuchi

FT-16D Type 1

For the Morrissey Group III Pro Series "What-if " Sports Car

By Rick Thigpen

Motor time for the Morrissey "What If" sports car.

I'm going to use an unknown vintage silver wire armature (French-Tradeship?) that I've used before. It ran pretty strong and I hope to make a motor setup that will help it last a while. What I'm doing is what I've read and what people have advised me works well. I'm sure there are more things I could do or things others would do differently. That's just fine. Everyone should do what they are comfortable with.....I do and I am.

Here are the motor parts I'm going with (for now). A Cox TT100 can with the blind bearing to be replaced with an end bell bearing and ARCO 33 magnets and shim. I'm going to use a Tradeship end bell that looks like a Cox but is molded of a higher temperature plastic (I hope). I'm also going to use shunted 16D brushes and brass spring post protectors in hopes of avoiding a melt down. The armature is a vintage silver wire "mystery arm":

My motor is supposed to look like a period Cox TT100 can with a TT150 end bell. However, I'll be using a Tradeship end bell that is made out of a higher melting point plastic. It's almost a dead ringer for the Cox-Mabuchi. On top is the Cox TT150-Mabuchi end bell. On the bottom is the stock Tradeship, and in the middle is my Tradeship with Mabuchi brush hoods and brass spring post protectors:

Here are some of the parts I hope will make this motor be fast and last. Vintage shunted brushes and brass spring post protectors and modern Champion medium brush springs and my "Invisible" brush spring insulation. My goal is to isolate the plastic spring posts from heat.

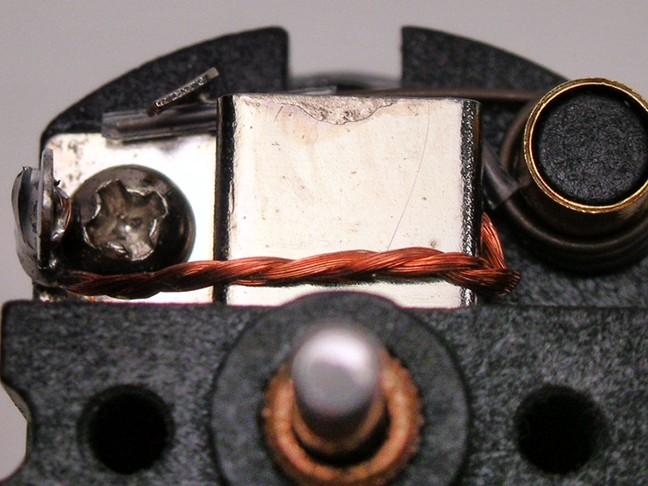

The hex brush holders are still just sitting on the plastic end bell and will get hot. We've all seen them melt down into the end bell. Here's something I've seen on some old motors. At first I thought it was just to help with electrical conductivity. It seems to me that this trick would also stabilize the brush holder if the plastic beneath it starts to get hot and soft. Note how the brush holder is soldered to the brush hood with high temperature solder. Maybe this is all a bunch of baloney but it looks cool:

This is what works for me when soldering brush holders to brush hoods:

1. Glass of water at the ready

2. 1,100 degree iron cranked full blast

3. Flow acid flux onto aligned brush holder and brush hood

4. Pick up dab of solder with tip of iron and touch it to joint for about 1 second

5. Throw that puppy into the glass of water muy quicko

6. Wipe tears from eyes from melting nylon if you were too slow

7. Run to sink and scrub end bell with Dawn and tooth brush (end bells do not like acid flux but the solder sure does)

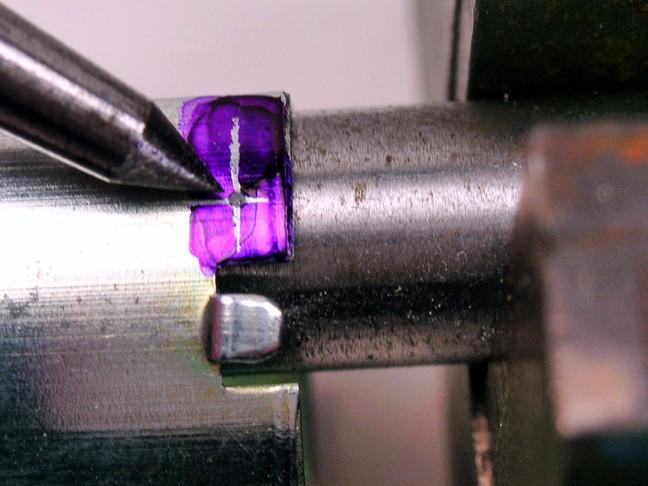

To attach the end bell to the can I used armature dye (which is really machinist layout dye) and scribed some lines on both sides of the can. You can use your cheapo dial calipers for this and your screws will end up in the same location on both sides of the can. I used a prick punch and a 3/8" steel rod held in a vise to back up the can during punching:

I'm not using self tapping screws because I don't like them. I'm going to use a common 0-80 machine screw that was available in the 1960's and before. This makes me happy. Please screw yours the way that makes you happy too:

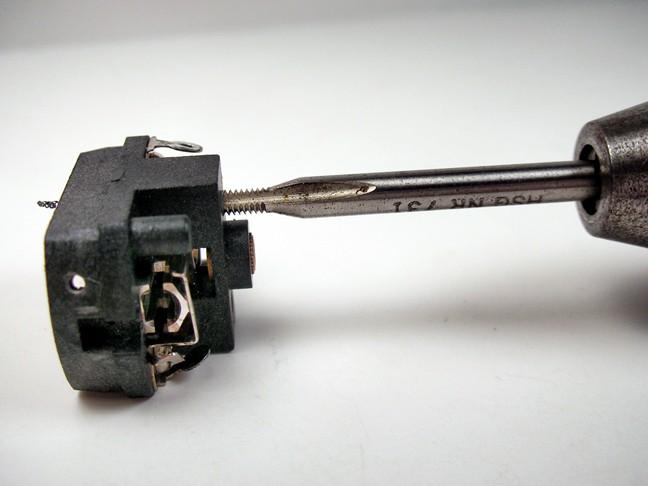

These end bells are a little brittle and can crack so I thought I'd forgo the self tapping mounting screws in favor of a 2-56 machine screw. When tapping a through hole like this end bell a "gun" style tap is handy. It pushes the chips out the back end of the hole. You can see the chip coming out the back of the end bell. You can also just crank away on a gun tap. You don't have to do the 2 turns in and a half turn out to break the chip as you would on a conventional tap. Just make sure you start the tap straight so your screw will be nice and square with the end bell:

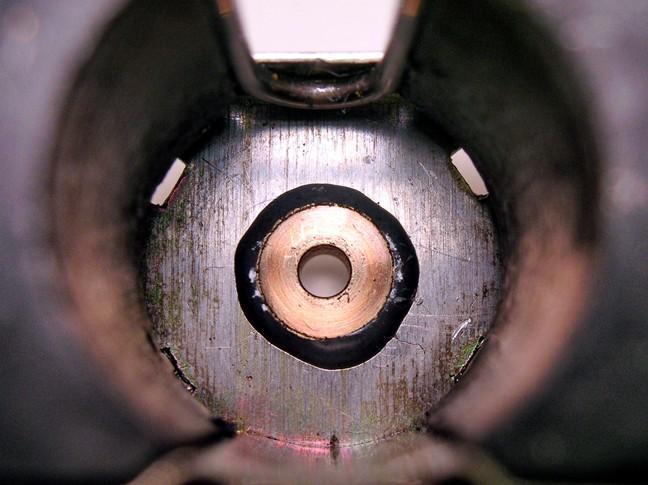

I cut off the blind bearing with dykes....hmmmm....maybe I should say side cutting pliers? Anyway, I'm replacing it with an end bell bearing. Back in the day we used to use Mabuchi bearings but today I need those to rebuild end bells. I have a pile of these Associated bearings so that's what I'm using. Here's the Mabuchi - Mura - Dynamic end bell bearing and the Associated bearing:

I've always soldered them in the can but this time I thought I'd try JB Weld metal filled epoxy. I put a dab all around the bearing flange and pushed it into the can. It left a little fillet of epoxy around the bearing like so:

No goobers on the outside of the can so it looks neat:

Next I'll stuff this mystery armature in and rig up the brushes, shunts and insulation:

Here on top is a stock modern Champion medium brush spring. On the bottom is the spring with my invisible (almost) Teflon brush spring insulation installed and the spring slightly bent to better fit the brush:

Here's a close up of the insulation. I pushed it farther than most do. I really want to isolate the spring and plastic spring post from the brush and shunt wire:

You can see here that the relationship between the spring, shunt wire and insulation:

And the finished motor:

I don't think the Pros were insulating their brush springs in 1967 so that's why I choose the clear Teflon tubing. You really have to look hard to see it on the car.

I should also mention that I messed around with armature to magnet alignment. Sometimes I hone the magnets. Sometimes I use an alignment tool and if things are out I'll open up the bearing hole in the can until things line up and then solder the bearing in.

This motor was pretty well in alignment (by some miracle) so I just epoxied the bearing in the can.

Anyway, it runs on the power supply.