Static Balancing

By John Havlicek

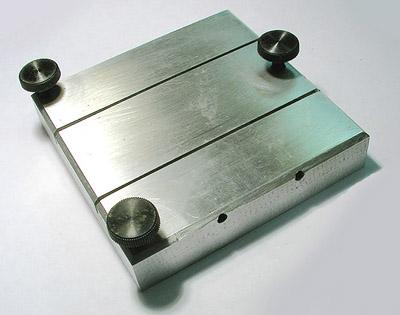

I asked Rick Bennardo at RGEO Products about doing a one-off balancing block and sent him a very rough drawing. Before I knew it, this showed up at my door:

It's really pretty EZ to do static balancing, and while not as accurate as dynamic balancing, it gets the job done pretty well. Here's the basics...with pictures:

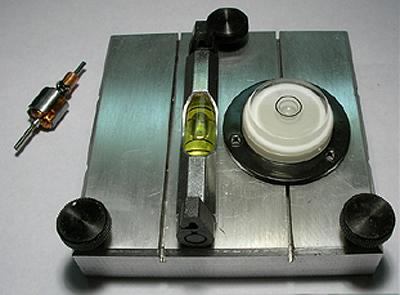

Set the block on your worksurface and if you want, level it using the screw-adjusters. You can use a little line level, a bullet or bullseye level...anything small will work OK, but these things aren't very accurate. I just generally put the arm on the blades right away as you find out quickly what level is. You then keep making small adjustments as you begin to balance the arm.

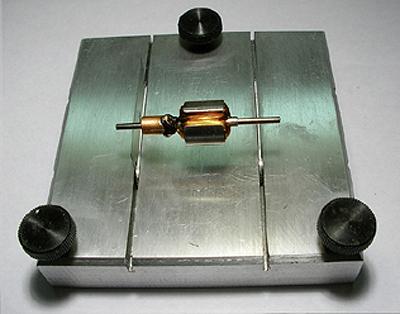

Install the blades and if you're lucky enough to get a balancing block from Rick, snug them using the setscrews. Place the arm on the blades and find the heavy side(s).

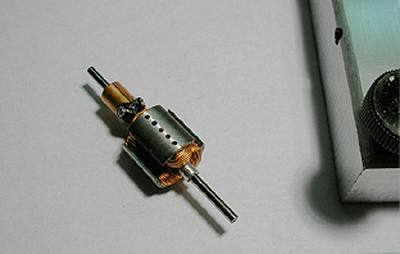

Mark the heavy side. I use a Sharpie and put a row of dots down the middle of the arm by eye. I'll use these as a guide when I start to drill. If you have a drill press and a fixture and can accurately locate the middle of the arm poles...MUCH better and safer too. Some people mark the end of the arm as to which pole is heavy...whatever works for you.

Start removing material by whatever means you have. On these Mura arms, a 1/16th drill bit is almost too large...so I have taken to drilling a series of shallow holes and even slotting the holes with the thin disc in a Dremel if necessary. If you drill too deep you can ruin the arm.

Keep at it until the arm doesn't have any apparent heavy sides. It should roll really slowly all the way across the blades without accelerating on any pole. It can take a while.