Tony P's 1975 ARCO-USRA Winner

Page 3

I mounted the front cross piece and ISO down stop a little too far forward and used the wrong size wire. I cut the sucker off and replaced it with a .055” cross piece and a .047” down stop.

Tony emailed me and reminded me that it would be much easier to follow his advice and attach the drop arm and ISO pivot tube before the chassis is cut in half. As an ISO newbie I didn’t because one slip with the cut off wheel and all my work would have been wasted. Now that I’ve cut the chassis in half I realize it was no big deal and I should have followed Tony’s advice. I will when I build my next one!

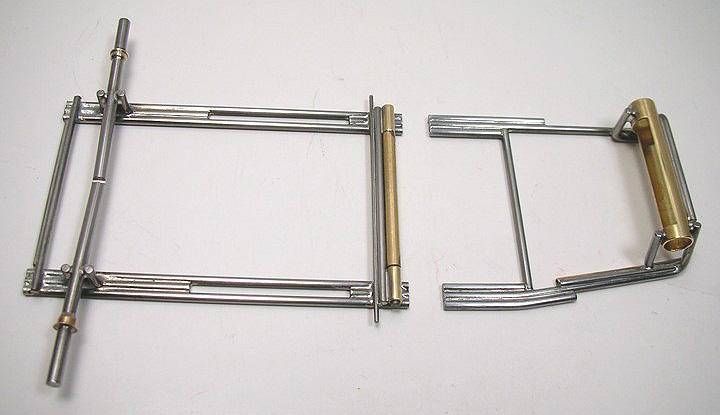

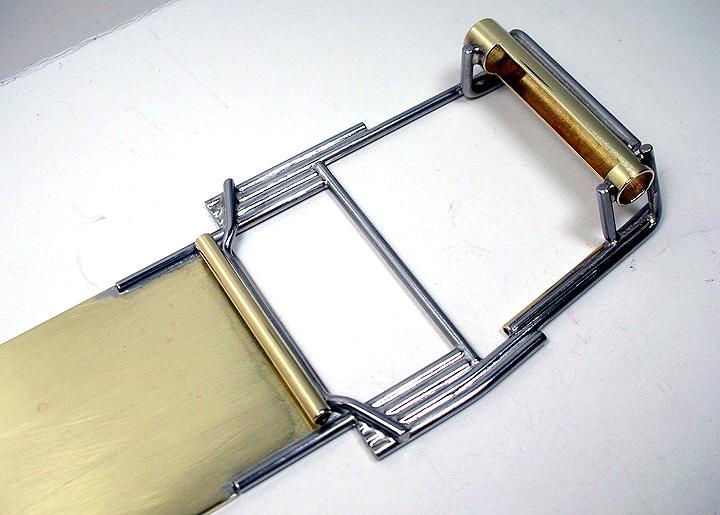

The drop arm needs to be attached to the back half of the chassis. But first I decided to add the plumber hinge tubes and bumper. This handy dandy jig is helpful. The bumper is 1/16” wire, the pivot tubes are 3/32” X .540” long and the bullet proofing wire behind the tubes is .047”. Tony may have used .030” and I couldn’t get to it to measure so I’m just guessing.

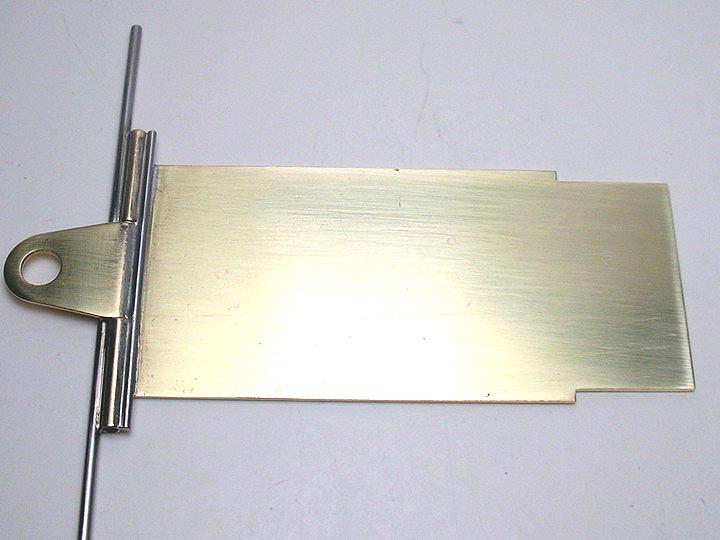

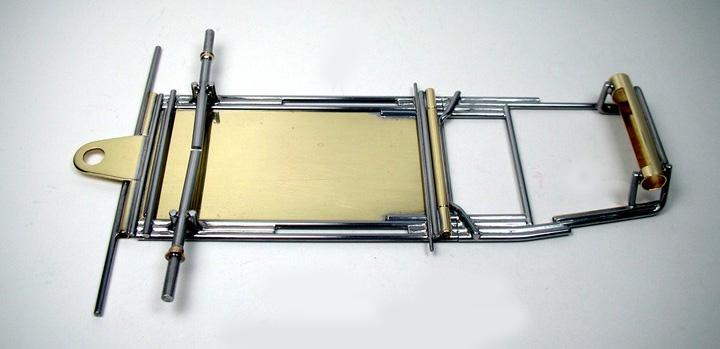

The drop arm out of the jig:

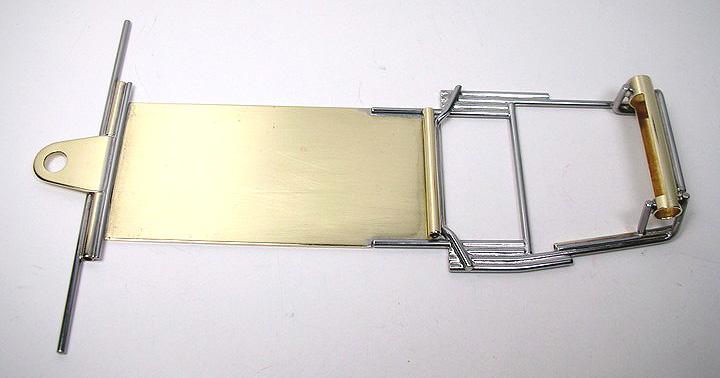

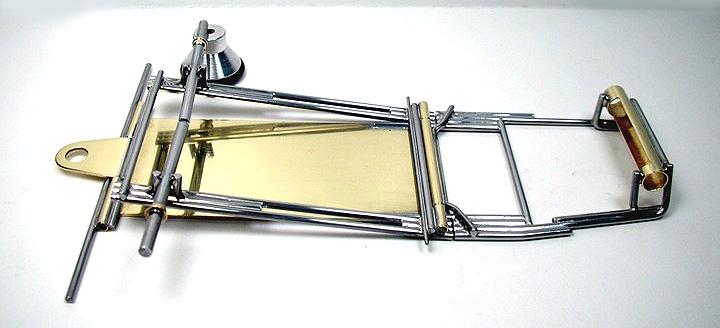

The drop arm is attached to the back half of the chassis by two 1/16” piano wire rails. The drop arm has .560” long notches cut in it to accept the rails. The ISO hinge tube needs to be attached to the drop arm but since the drop arm is only .030” thick and the rails are .062” there is a gap between the ISO pivot tube and the drop arm. Tony used a .055” piano wire brace for this. This piece is bent to reach down to the drop arm and tie everything together. Here is everything attached:

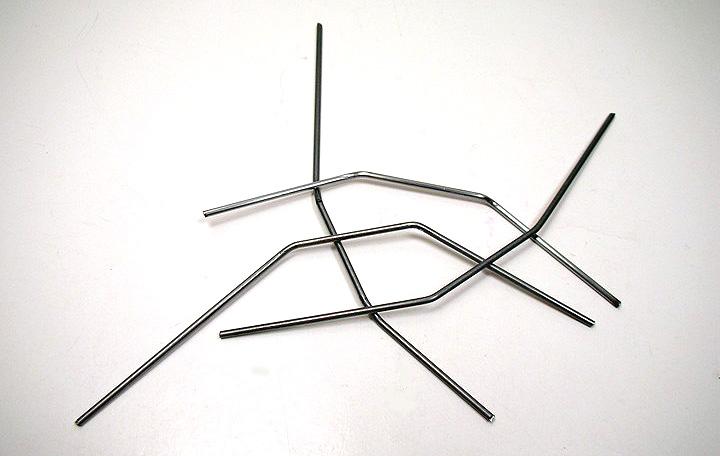

Now, I found this .055” brace somewhat challenging to make. Challenge one through four:

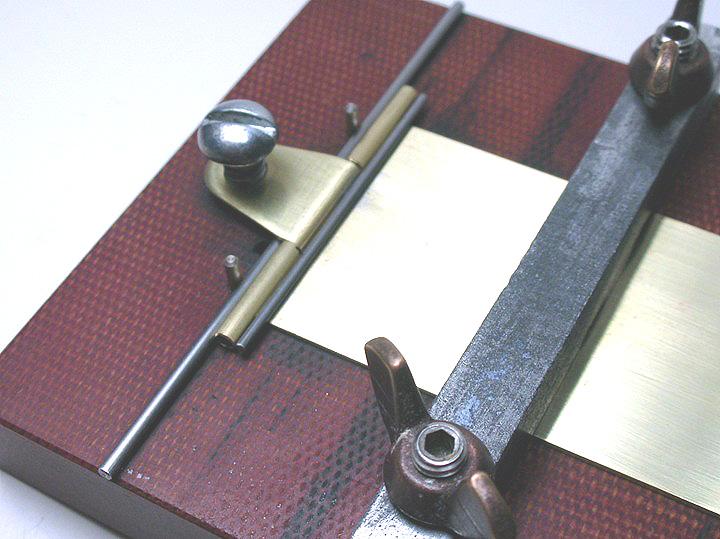

But what’s that old saying, “fifth time is a charm”? Finally a good one:

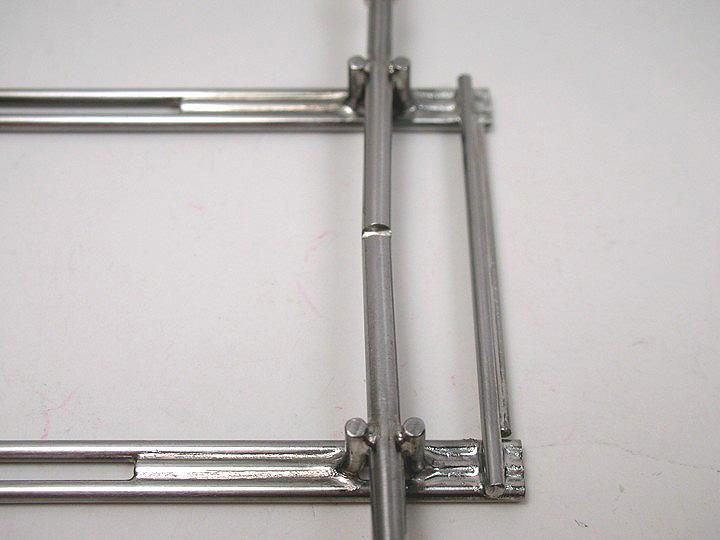

Here are some closer pictures of how everything gets tied together:

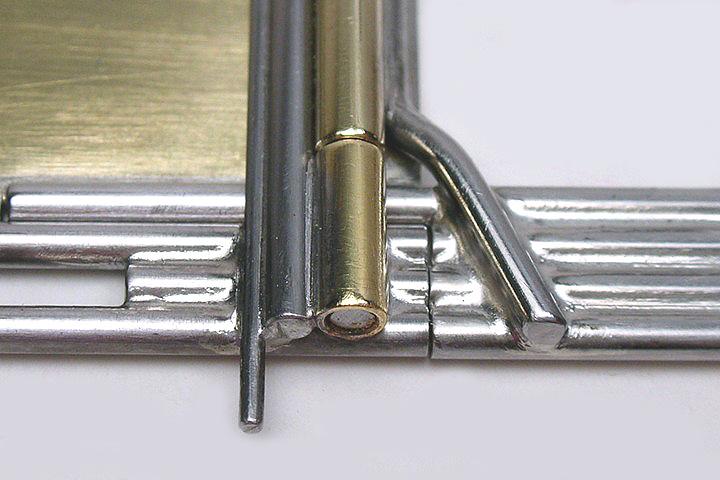

A close-up of the chassis front and rear interface:

The chassis with the ISO front end installed:

Next it’s time to hang the plumber rails and pans….. (Click here)