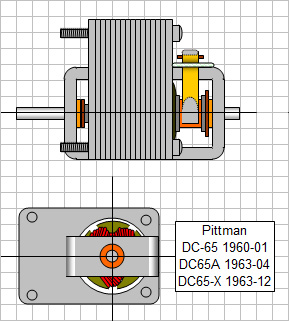

Pittman DC-65, 65A, 65A-6 and 65X

Photos courtesy Bob Steere

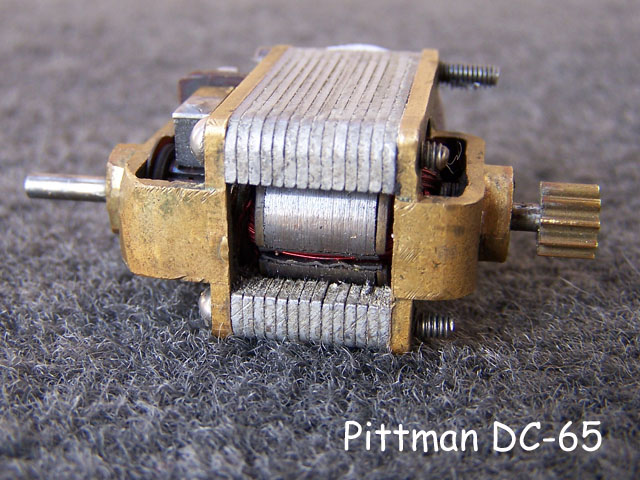

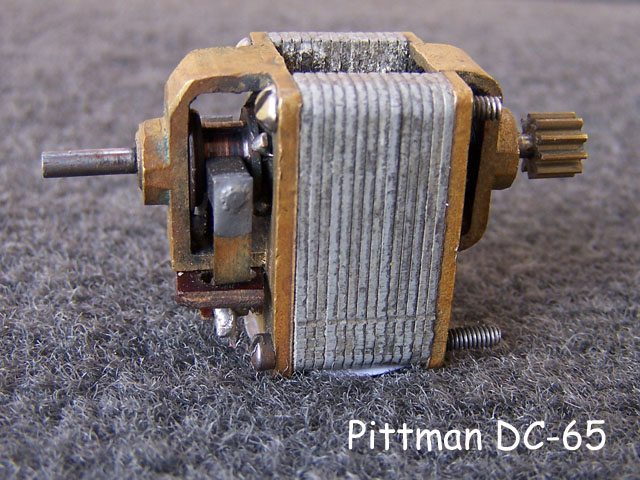

The DC-65 type was the smallest "Laminated Field" motor Pittman made. As a result, it was also Pittman's most popular laminated field motor among road (as opposed to drag) slot car builders.

Laminated field motors have a more efficient magnetic circuit than open frame motors such as the DC-195/196 because the "lines of force" from the magnet are more effectively guided, and therefore remain more concentrated, by several thin steel plates (called laminations) instead of a single solid pair of pole pieces. Just as the armature works more efficiently when it is made up of numerous laminations instead a solid chunk, so do the magnetic field pieces.

Because of the way they are configured, laminated field motors tend to assume a characteristic "ice cube" shape, with the armature offset towards one end. When laid down flat, this makes then clumsy to build into an inline chassis, so they are much better suited to a sidewinder configuration. Laminated field motors generally have more torque than open frame motors which, in the 1960s, made them a favorite for drag racing.

The original DC-65s were vintage 1959 or so (as you can see on the spec sheet, which was "revised" in March of 1960). They had a 14 lamination field, and cast brass end frames. Cast brass was really old school! The five pole armature and fine wire windings made them an excellent model train motor, but far from optimal for slot cars.

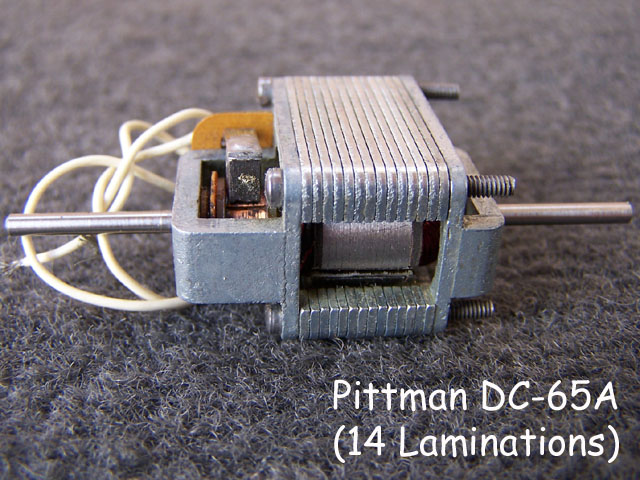

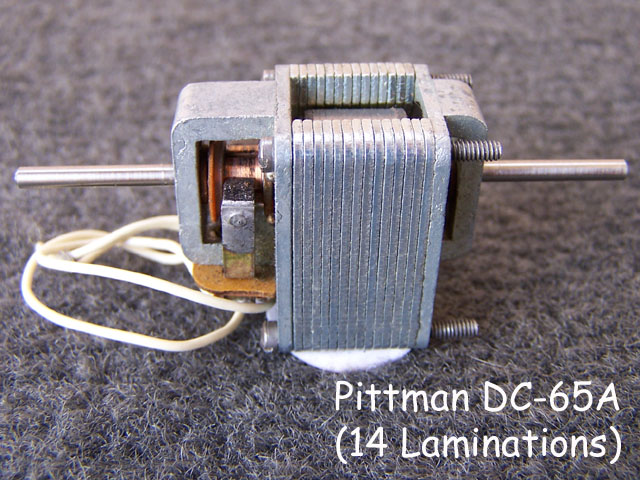

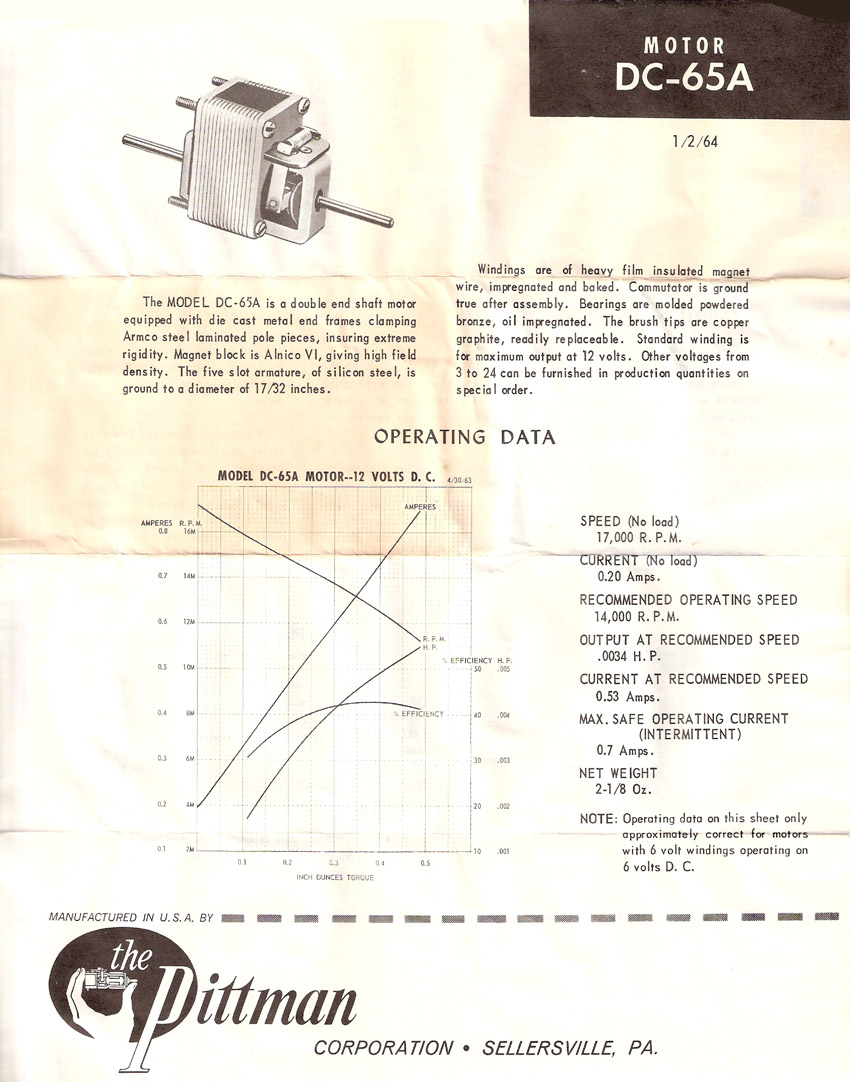

In early 1963, Pittman introduced the DC-65A. The brass end frames were gone, replaced by white metal castings. The motor featured about 20% more RPM, even though it had the same electrical ratings (0.7 amp maximum intermittent at 12 volts). As important and desirable as the higher RPM might have been, nothing is free in motor design, so the higher RPM came at the cost of lower torque; the "Operating Data" graphs on the specification sheets clearly show this.

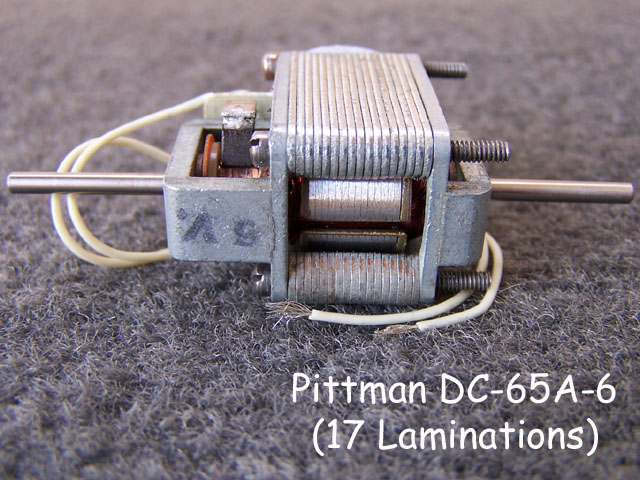

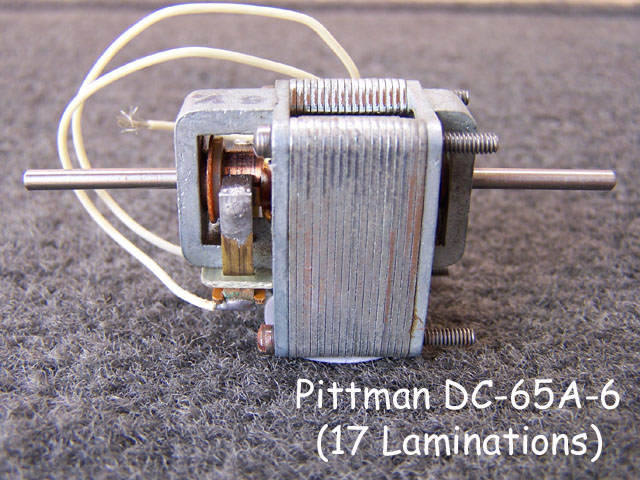

Later in 1963 Pittman introduced the DC-65A-6. It featured an electrical upgrade to 6 volt armature windings and a design improvement of 17 thinner field laminations replacing the 14 thicker ones on the DC-65A. The thinner laminations improved the efficiency of the magnetic circuit, and the 6 volt windings produced more amp-turns in the armature, resulting in greater torque and somewhat higher RPM ratings. But there was yet another improvement to come.

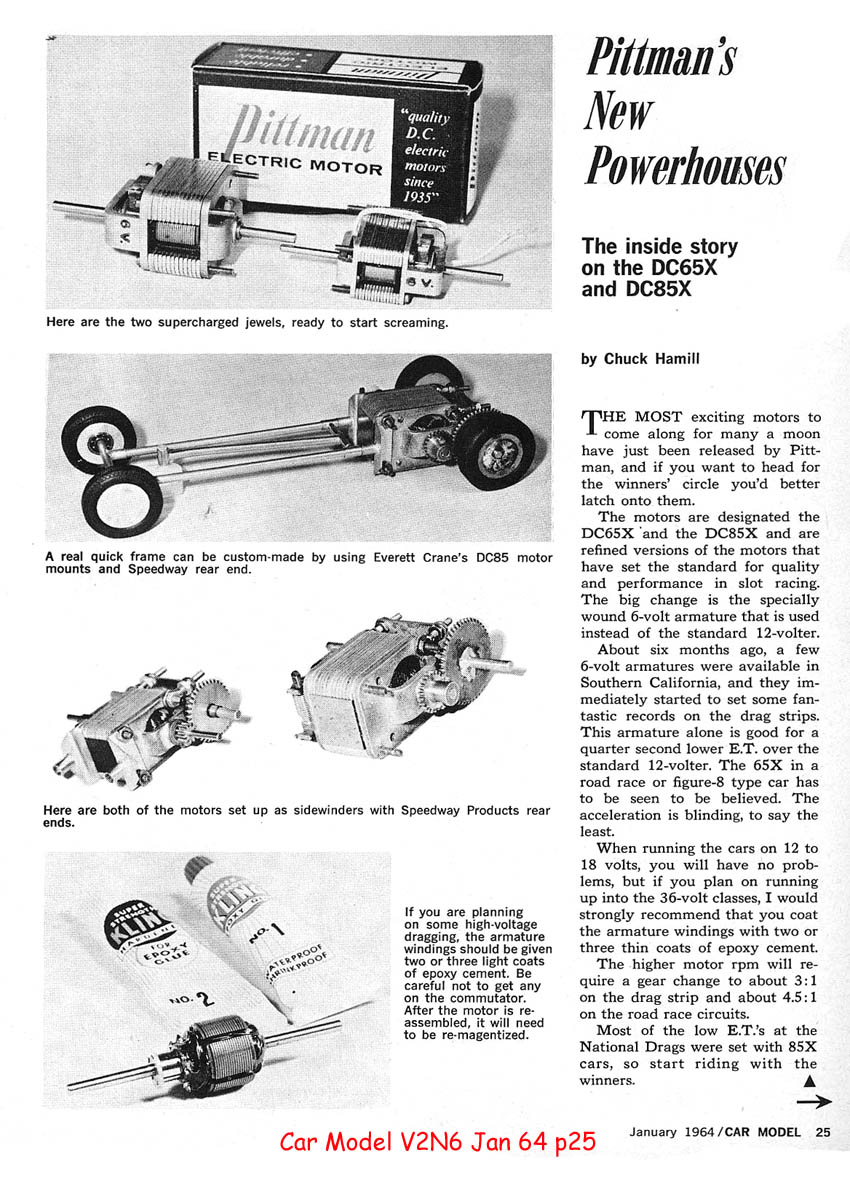

The last step would come at the end of 1963, when the final version of the DC-65 series, the DC-65X, made its appearance. The photograph in the Car Model magazine article below purportedly shows a DC-65X, and it is marked "6V.", but it also has the same 14 laminations the DC-65A 12 volt motor had, as opposed to the 17 laminations in its direct predecessor, the DC-65A-6. Very strange.

For more information about the DC-65X click here.