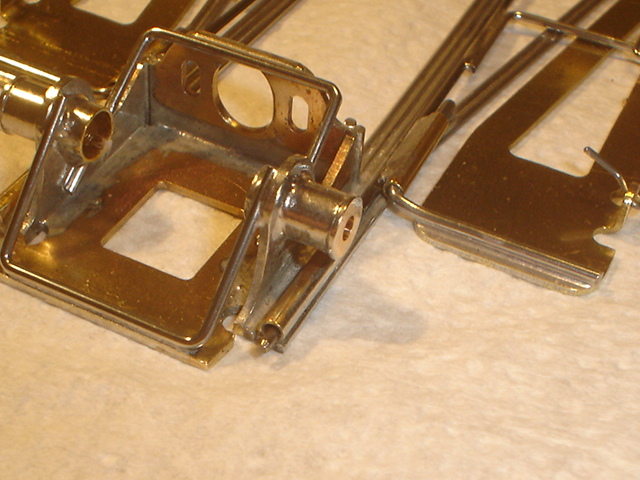

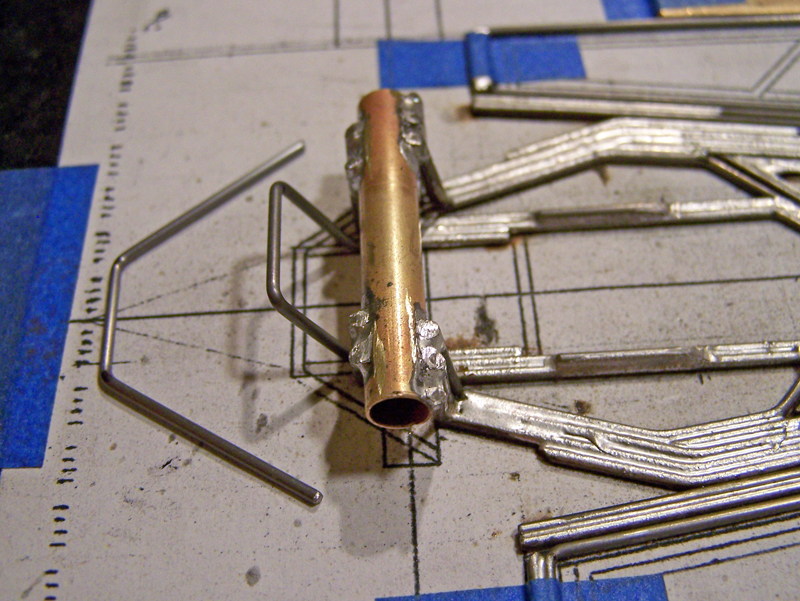

I used to build with axle tubes. Now, I have to believe that the wider brackets (with bearings fit snugly into their holes) are lighter and stiffer (except in the section where the motor is, which might be the best reason to use narrow brackets with axle tubes).

I used to bend the axle tubes but I used to get crashed by the faster guys passing me (and not being patient as I always try to let them by). Now, I am nearly as fast as the fastest guys, which means I don't see people passing me on either side nearly as often.

I have only bent one bracket (it was a bump-out from an existing crash putting me into on heck of a rider wall shot - the place went silent...) but I had ball bearings, which tolerated the very slight misalignment and I didn't even know it until I checked the car out after the race.

I think the wider brackets (use .040 half hard brass, .050 is too thick...) are the way to go with the steel mainrails a good distance away from the can and the magnet flux pull they can create if they are too close or have too much volume of steel (big wire).

I have pondered making a 5 bend bracket, just wide enough to support the motor can faying surface, then going at a 45 degree angle to the rear upright areas, parallel right where they reach the rear axle bearings. From an engineering standpoint, that would be very stiff but would require special die tooling to make.

Also, the literal tech Nazi's might say that it is not a 3 sided bracket...anyone want to chime in on whether this would be legal? It certainly meets the intent of the rule, methinks.

As I look ahead to avoid crashes, I find I am bending my chasses less - maybe that's the secret?

Brace it, race it, bend it, mend it.

Or just keep it in the slot and hope for the best,

AJ

Sorry about the nerf. "Sorry? Sorry? There's no apologizing in slot car racing!"

Besides, where would I even begin? I should probably start with my wife ...

"I don't often get very many "fast laps" but I very often get many laps quickly." ™

The only thing I know about slot cars is if I had a good time when I leave the building! I can count the times I didn't on one two three hands!

Former Home Track - Slot Car Speedway and Hobbies, Longmont, CO (now at Duffy's Raceway), Noteworthy for the 155' Hillclimb track featuring the THUNDER-DONUT - "Two men enter; one man leaves!"