Pittman DC-196, 196A & 196B

Motor photos courtesy Bob Steere, from his collection

Additional information and photography courtesy Don Siegel, John Secchi, Jack Beers, Fred Correnti and Rick Thigpen

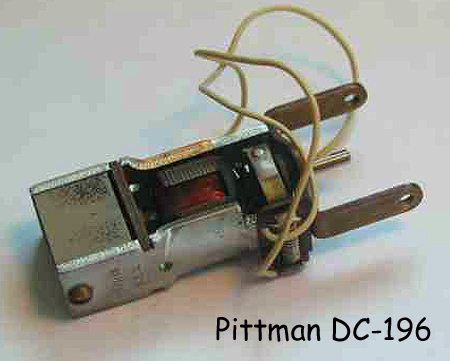

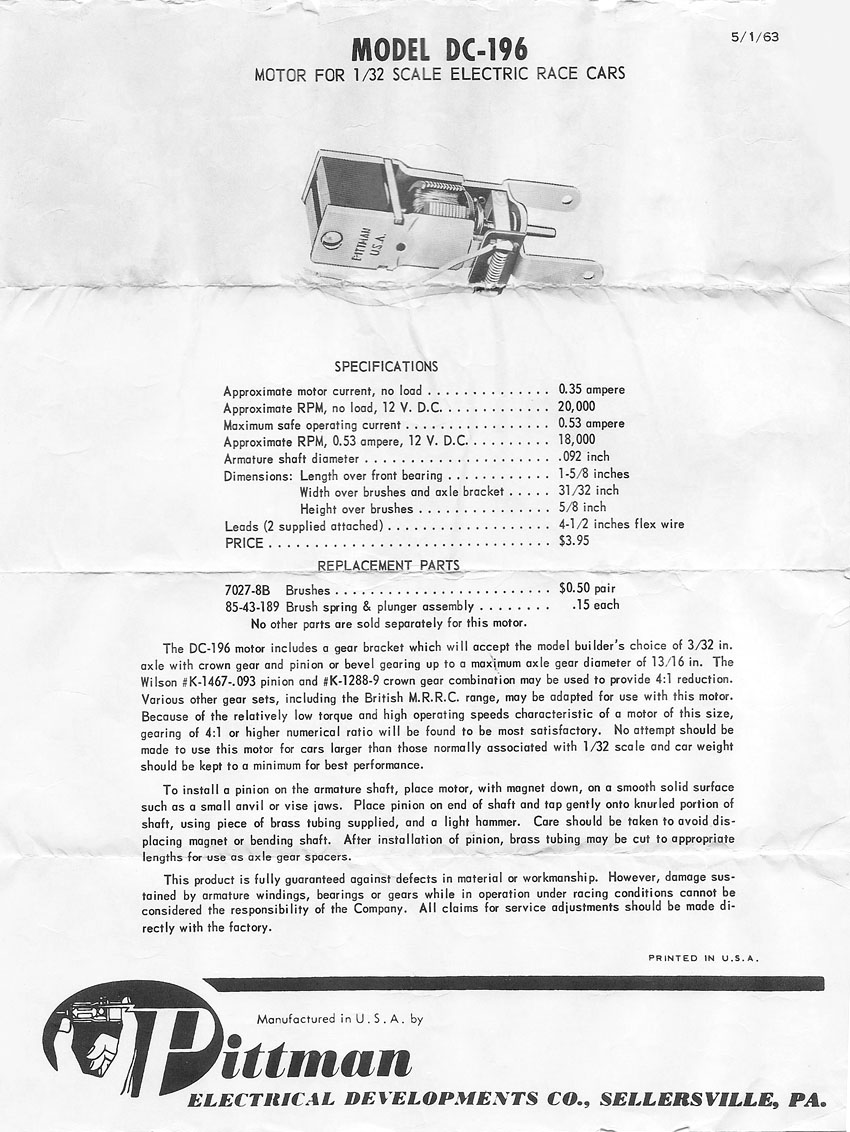

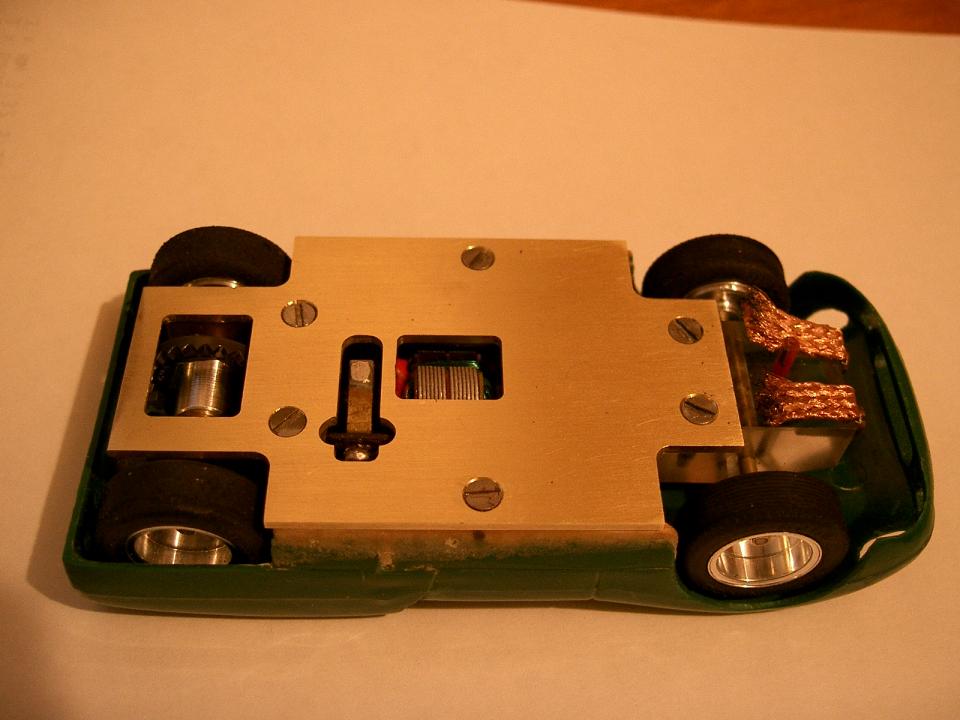

Following the DC-195A, the next generation of Pittman's smallest motor, which became available in mid 1963, was the DC-196. The DC-196 had two significant design improvements over its predecessor. The first was incorporating an integral formed sheet brass axle bracket, and the second was replacing the five pole armature with a three pole. These two improvements, plus slightly heavier windings on the armature, made the DC-196 an immediate and lasting hit with builders and drivers alike.

Don Siegel writes: “I've run a couple straight 196 motors, and they're surprisingly fast. Seem to be epoxied from the factory too, at least the one MIB one I have is.”

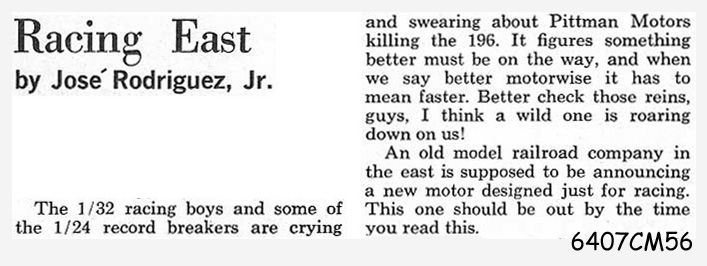

Production of the DC-196 went on for most of a year until early 1964. Then rumors began to leak out that Pittman was going to replace the 196, which elicited some unhappy noises from those otherwise happy builders and drivers:

Note the date on the Car Model magazine column clipping above; the July issue of Car Model was published and put on sale in June 1964, which means Jose Rodriguez Jr. probably wrote this piece in late May 1964.

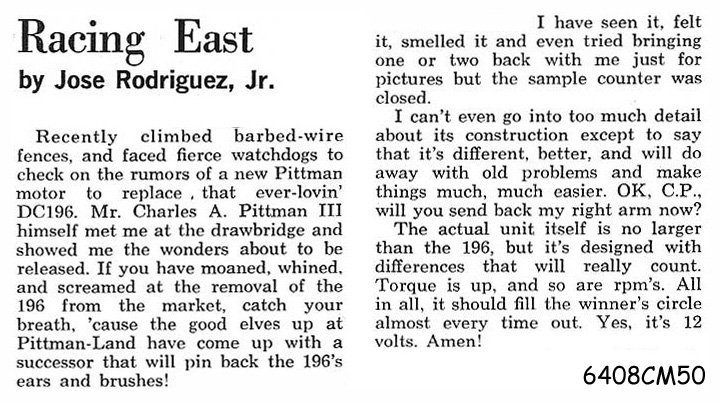

By sometime in June 1964, Jose confirms the existence of a new product to replace the DC-196, but appears to have been sworn to secrecy about it by Charles Pittman himself. This clipping was Part of Jose’s column in the August 1964 issue of Car Model, which went on sale in July:

Jose was clearly being overly-dramatic, but Pittman was apparently playing the anticipation game to the hilt because their new motor, the DC-196A, was already in production and first deliveries had already made their way through the distribution system to retailers, then to builders and into slot cars no later than early July.

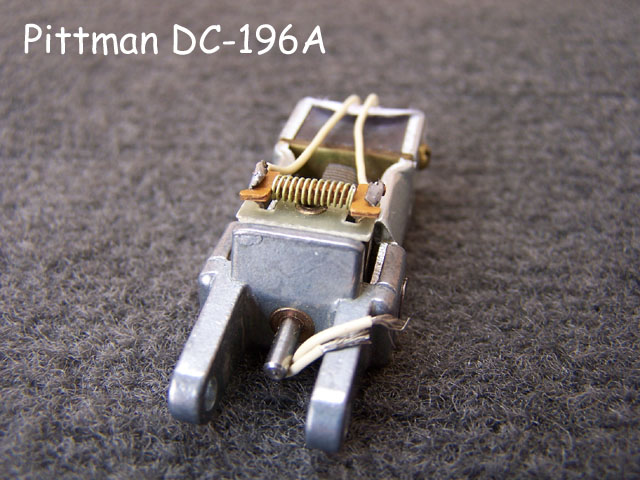

The DC-196A

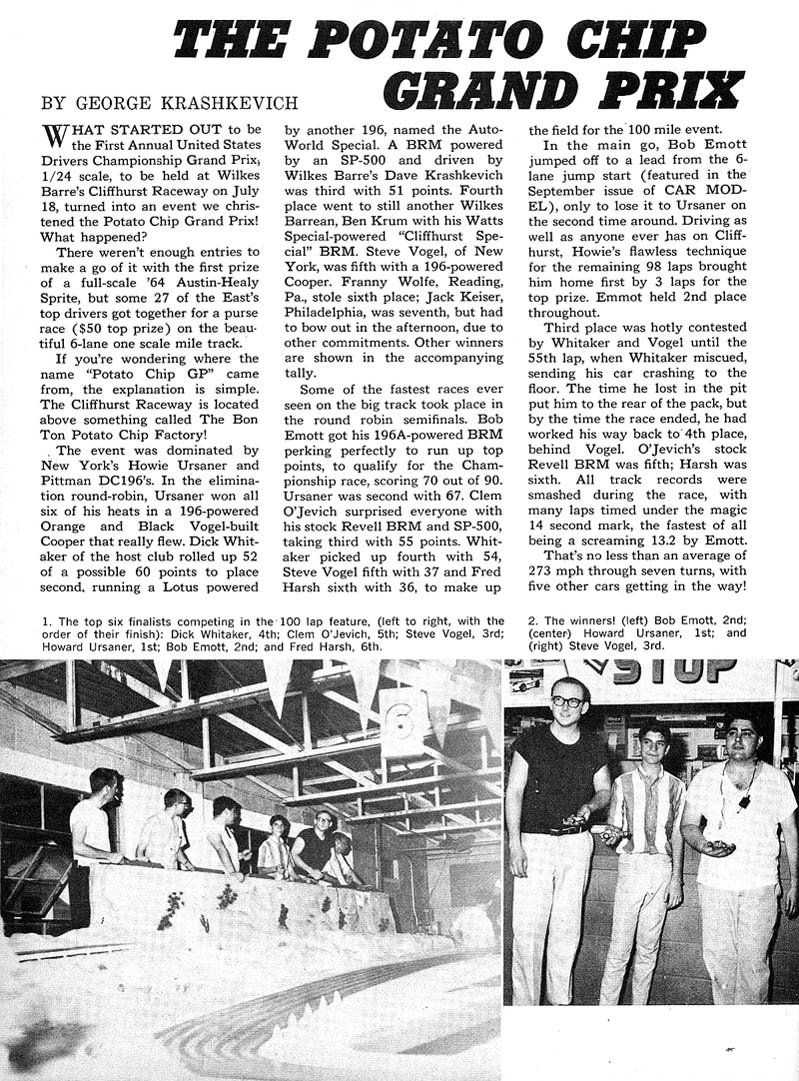

On July 18, 1964 the First Annual United States Drivers Championship Grand Prix was held at Cliffhurst Raceway in Wilkes Barre, PA. It became known as the Potato Chip Grand Prix:

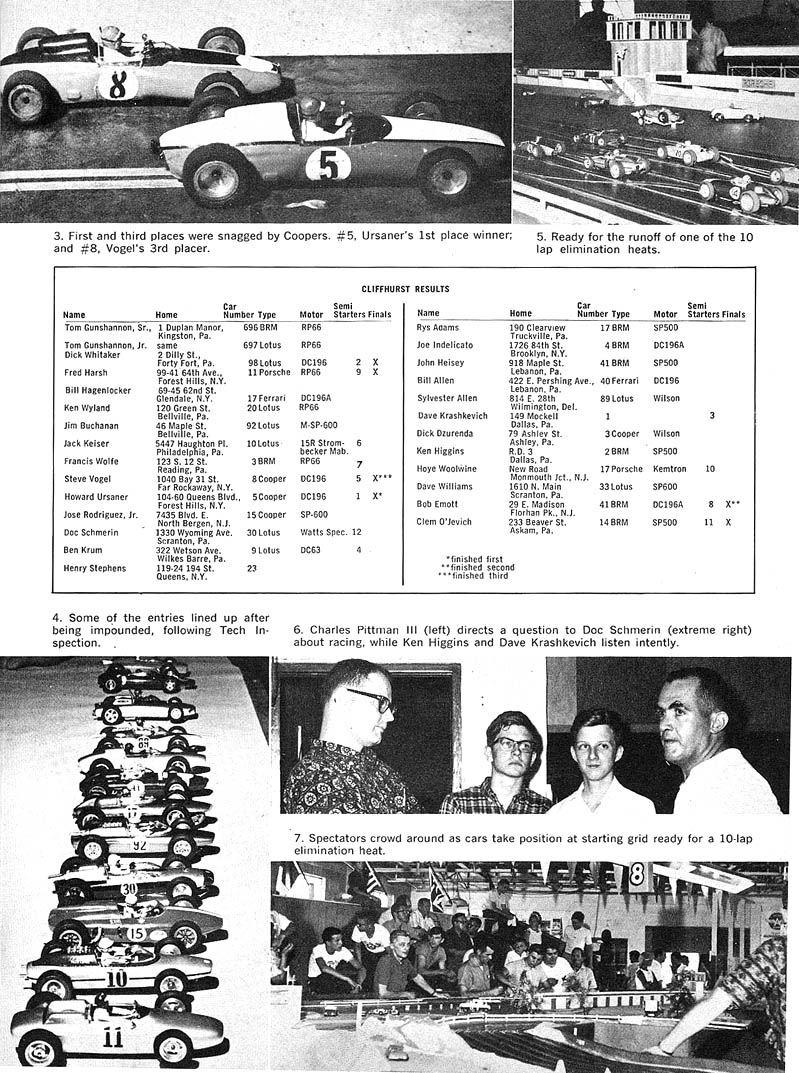

There are 27 entries listed on the second page. Of those, there were at least thirteen motors manufactured by Pittman, including four DC-196s and three DC-196As. There were eight Mabuchis, including three FT-36s and four FT-16s. Of the six drivers that made it to the Main, their six cars were powered by five Pittmans and one Mabuchi.

The winner was Howie Ursaner driving a DC-196, second was Bob Emott driving a DC-196A, third was Steve Vogel, driving a DC-196, and fourth went to Dick Whitaker driving yet another DC-196. A 1-2-3-4 sweep; how's that for dominance? Clem O’Jevich’s Mabuchi powered car was fifth, and Fred Harsh took sixth with an RP-66 powered car.

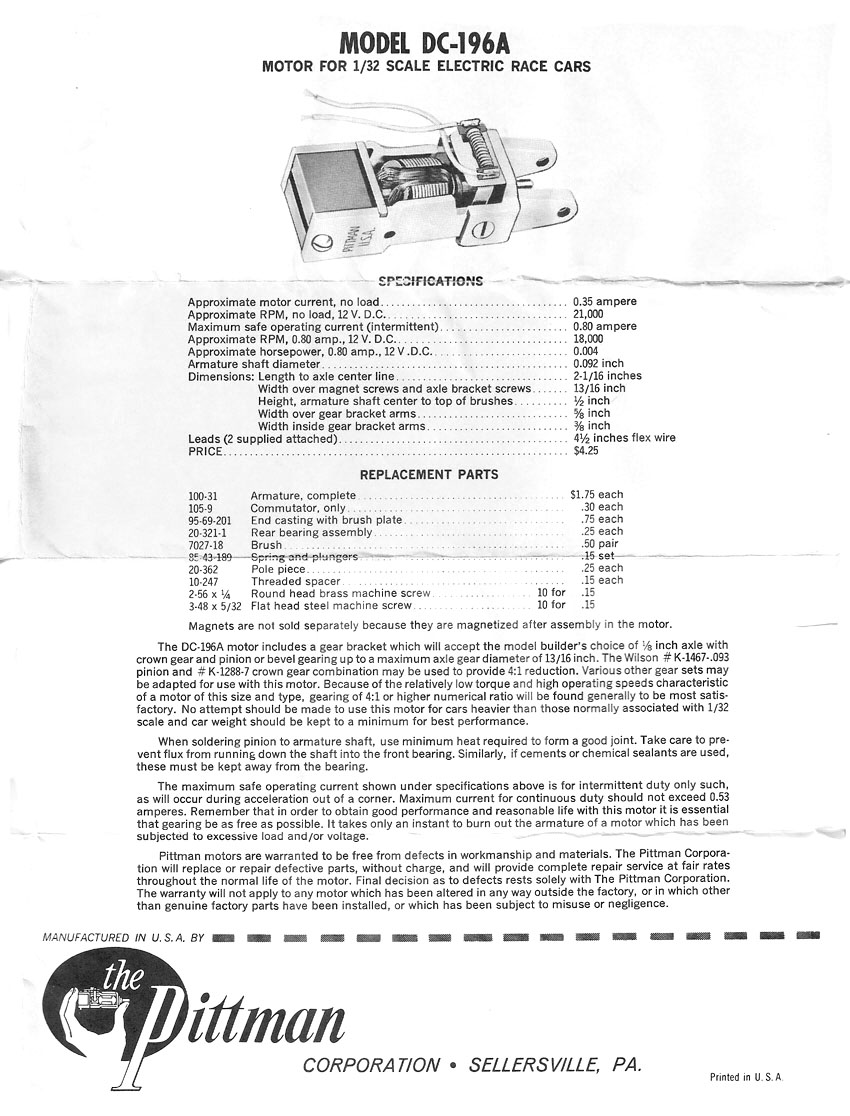

Pittman’s new DC-196A motor had received an upgrade and two design improvements. The upgrade was again heavier windings on the armature. While the operating RPM was the same as previous models, the "maximum safe operating current" was now .80 amps, which meant the motor was potentially generating more torque.

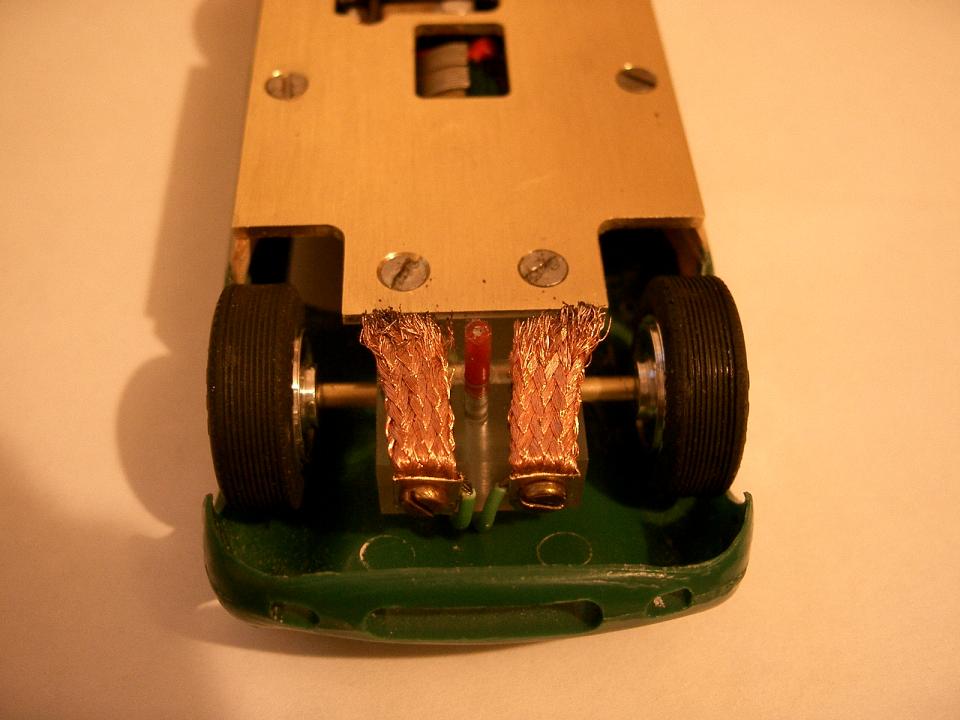

The two design improvements were incorporating a stronger and heavier, although considerably narrower cast axle bracket, and relocating the brush assembly so that it would be on the top of the motor.

While the cast axle bracket and overhead brush assembly seemed like a good idea, not everyone was happy with it. Don Siegel writes: “From what I remember reading at the time, the 196A was actually very poorly received, because it was so tall - they had trouble fitting it in a lot of 1/32 cars, not just the F1s but also a lot of sports cars, which are pretty low down in 1/32... and I don't think it was all that much narrower than the 196, except for those brushes... I've experienced this myself in fitting motors to 1/32 cars. The Atlas often winds up being the choice, just because it's so compact in all directions - and probably a tad faster than a DC-196B, in the BB version. Shifting the brushes made a lot of sense (and made it easier to fit a 65X arm...), but the brush gear was way too high - lots of comments by Hagenbuch and several others if I remember right.”

Pete Hagenbuch and several others did in fact have critical comments, and voiced them in their columns in Car Model Magazine. Here’s a sampling from the September - November 1964 time frame:

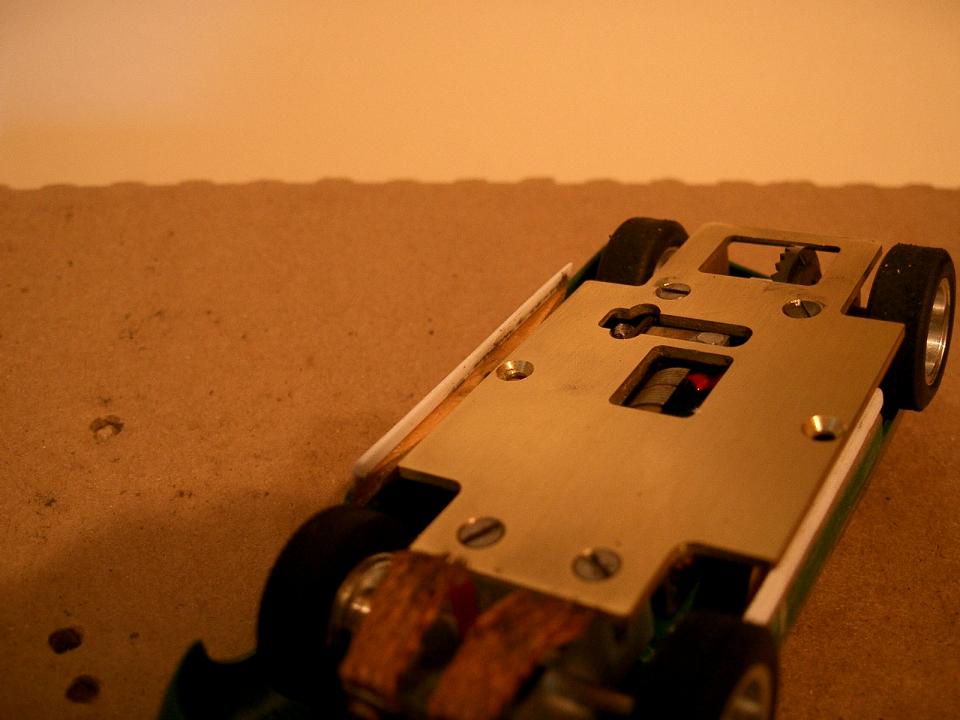

Pittman had apparently decided that even if they made their new cast axle bracket narrow enough to fit scale GP bodies, there would still be enough room for brass bevel gears, which were commonly used. They chose 3/8” width between the gear bracket arms and a bracket arm length adequate to fit a 13/16” diameter gear.

Unfortunately, this turned out to be both too short (for bevel gears) and too narrow (for crown gears), as Chuck Hamill points out in his column above. Higher ratio bevel gears bind up against the bottom of the bracket, and all but a very few crown gears are too wide for the space between the arms.

In addition to this, the old lever style brush assembly with vertical brush arms and coil spring at the top was simply too tall to fit into many smaller bodies, as Chuck also points out.

The short and narrow bracket was enough of a problem that by November, 1964 there was already an aftermarket "fix" available, as reported by Oscar Kovaleski:

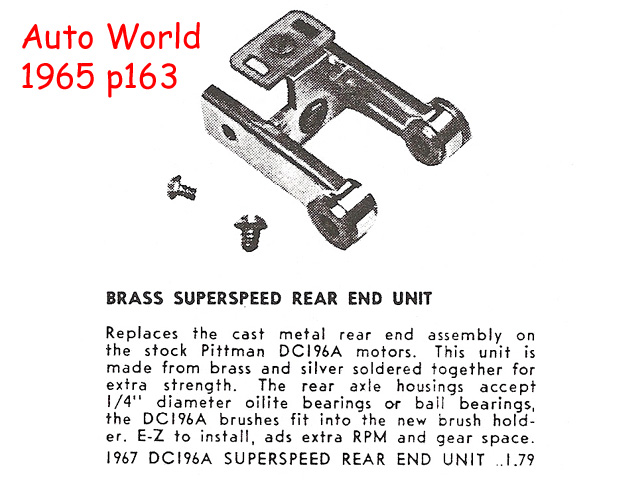

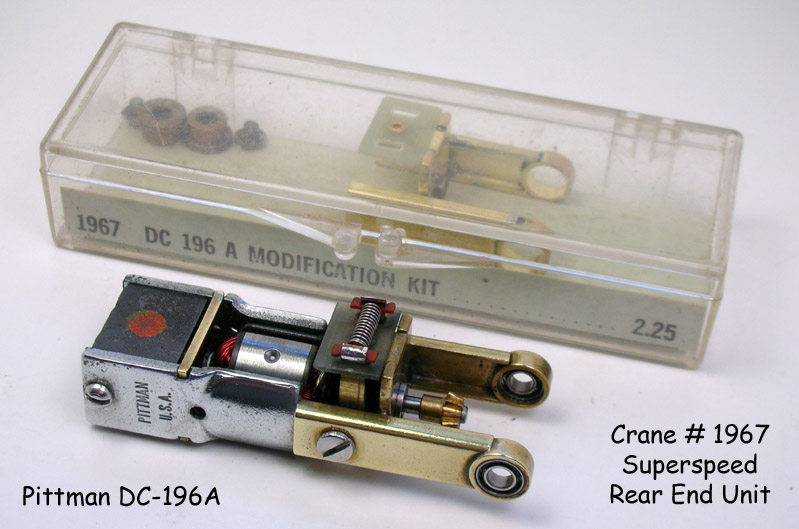

Here’s what it looks like:

The too-tall brush assembly was on the other hand a more difficult problem to resolve. Pete Hagenbuch simply wanted Pittman to put the brush assembly back where it was before:

And Jose Rodriguez Jr. reports Pittman at least acknowledged the problem, but had for whatever reason, decided not to change the DC-196A:

So this is where the history of the DC-196A ends; Pittman withdrew it from the market. What happened next may be a matter of semantics; Pittman did in fact not change the DC-196A; they replaced it.

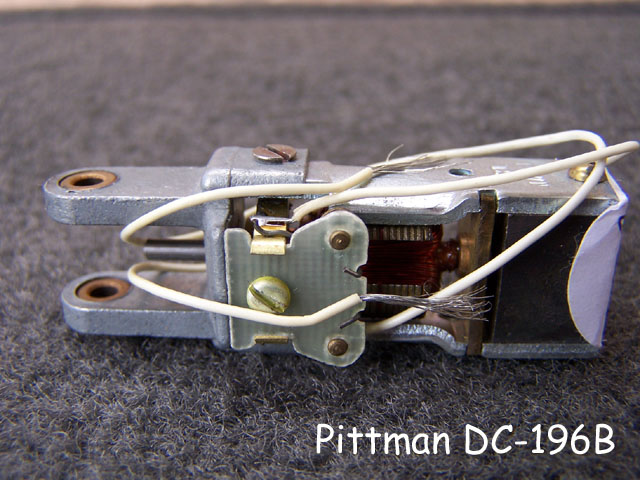

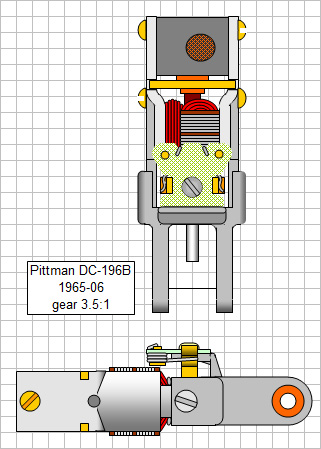

The DC-196B

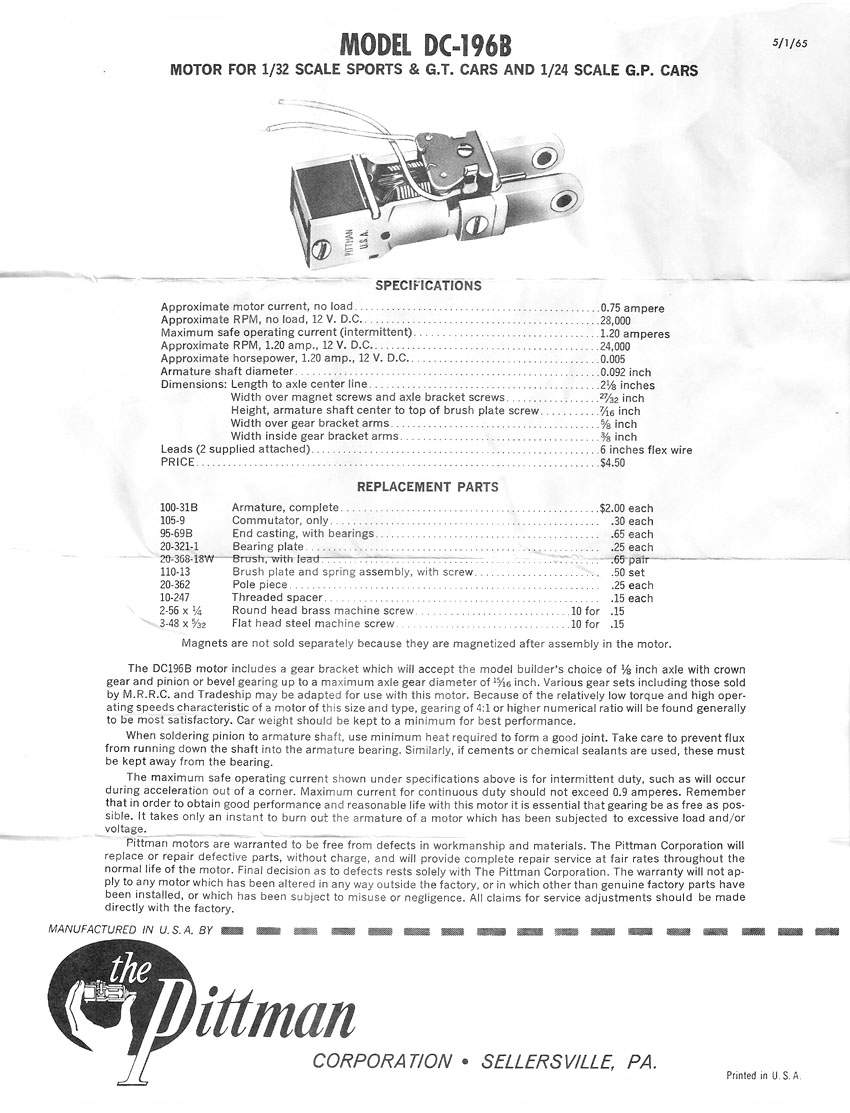

On May 1st, 1965 Pittman introduced the DC-196B. The “B” was to be their last iteration of the type. The Japanese tin can motors were making significant inroads into Pittman's dominance, and pretty much everyone knew it.

This time Pittman made serious attempts to “get with the program”.

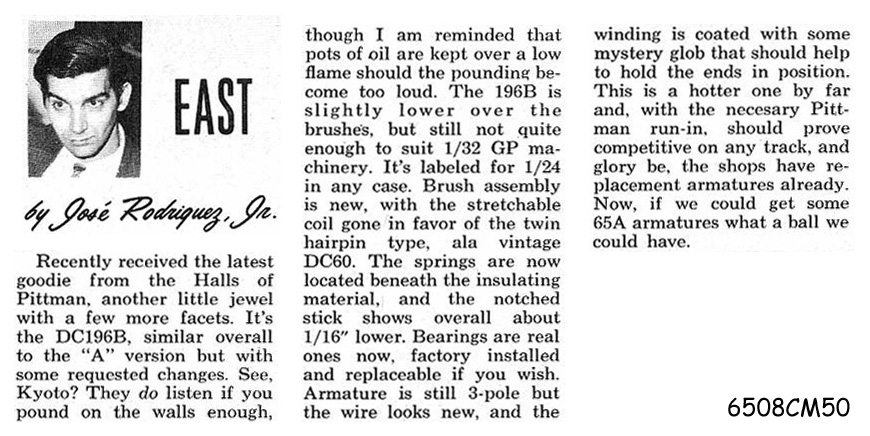

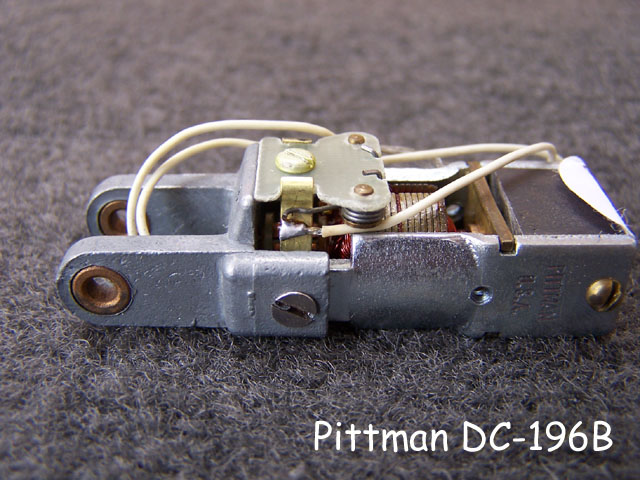

They replaced the old style lever action brush assembly with a double torsion coil spring brush assembly. Now the overall height of the brush assembly from motor shaft center-line to the top of the brushes was decreased by 1/16”, allowing the motor to fit better inside smaller and lower bodies.

Pittman also lengthened the cast axle bracket arms by 1/16” so they would fit a 15/16” diameter gear. However for unexplained reasons they did not increase the width between the arms.

In the armature department, they began doing what the tin-can guys had been doing for some time; winding for horsepower. The May, 1965 DC-196B specification sheet indicates the "maximum safe operating current" is 1.2 amps; up 50% from the DC-196A (and up 240% from the DC-195A), with an operating speed at that amperage up 33% from the DC-196A at 24,000 RPM. These were big improvements.

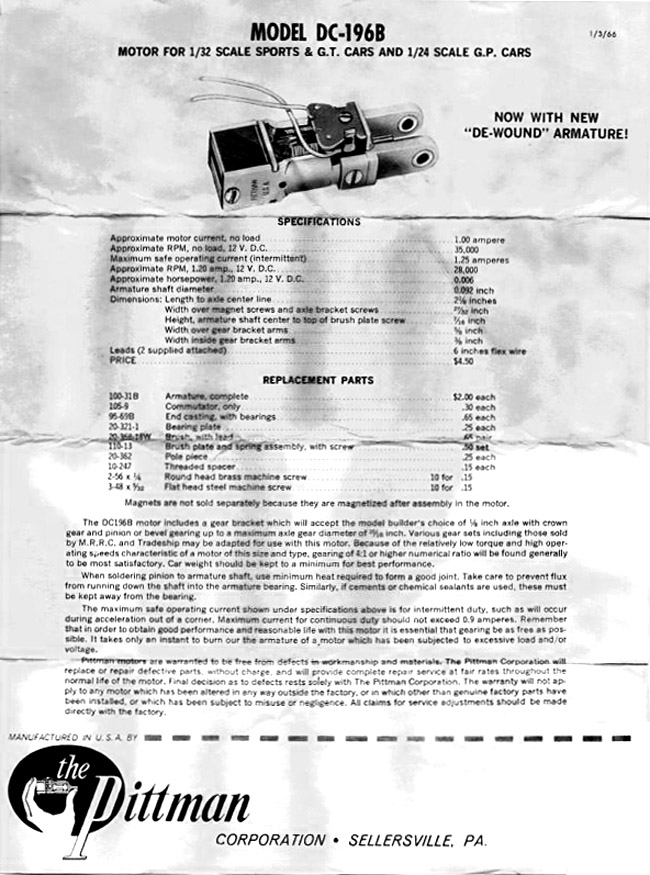

Later on, in a January, 1966 specification sheet marked “Now with new de-wound armature”, the DC-196B operating speed at 1.2 amps is listed at 28,000 RPM; about 16-1/2% faster than the earlier DC-196B. Pittman may have been starting to think more in terms of their motors being made up of upgradeable components (think “setup” and “armature”), instead of a single integrated unit.

Apologies for the poor scan quality; it’s the only one I’ve got. If anyone has or can make a clearer, higher resolution scan, please send a copy and I’ll post it up.

In April and May, 1966 Pittman took out duplicate ads in Car Model and Model Car & Track magazines promoting not only their de-wound armature, but the fact that the DC-196B would now fit in “ANY body” in either 1/24 or 1/32 scale. These were to be their last ads for the DC-196B.

Unfortunately, all of this was still not enough to stem the tide; the inherent superiority of the can type motor in a slot car application had overtaken the "external magnet" configuration in open frame motors. Can type motors simply have more potential for improvement than open frame motors. Pittman had pushed open frame motor technology as far as they were willing to go with it and it was not enough. The DC-196B was a good motor, many times better than the original DC-195, however it was also too little too late.