[

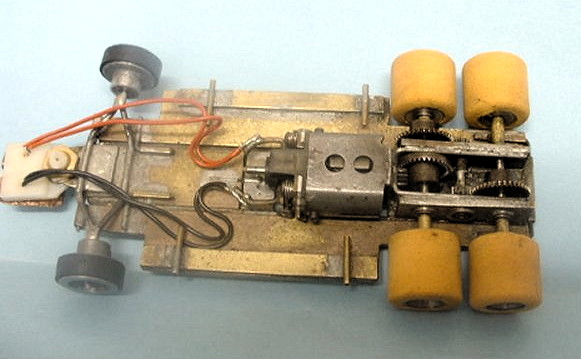

It's a pinion on the motor meshing with a crown gear on the first rear axle. On the outside of that axle bearing is a spur gear. Then that spur gear meshes with a pinion on an idler shaft. There is another pinion on the idler shaft that meshes with a spur on the second rear axle.

I want both rear axle to turn at the same speed. Is that what is happening here?

If so, does that mean the actual gear ratio for the first rear axle is being set by the motors pinion and crown gear as is normal. And for the second rear axle I can use any number of teeth on the other gears as long as both spurs on the axles and both pinions on the idler shaft are the same?

You "Gearologists", please help