Just bought an NOS Ram 850 and it came today. It's before my experience so a little information on these motors would be apreciated. It's a seven-pole 18 motor laminations. Rated 6 volt. So... anyone know:

1) Magnet material? Not ceramic I don't think

2) Armature wind? (it is done two poles at a time)

3) Gear and tire size apropriate for drags (I think many were so used)

4) Replacment source for brushes (future use)

5) Anything else you think is useful to share

Thanks.

Ram 850

#1

Posted 22 July 2013 - 06:58 PM

So hard a judge they hope never to meet as themselves.

#2

Posted 22 July 2013 - 08:19 PM

Picture, pretty please?

I think that most RAM motors take the same brushes as Pittman DC85, to be verified by Pittman/RAM experts, I am not one...

Philippe de Lespinay

#3

Posted 22 July 2013 - 08:49 PM

Well, as far as I know....

1. Alnico

2. Could be either 3v, 6v or 12v but you have a good one. No clue on actual wind.

3. Think tall, 2-2.5:1 but trial and error because they generally ran on 36v back when .

4. Same as Pittman 85, etc., and they seem to be around but wear slowly.

5. They need more brush spring, again trial and error depending on voltage.

6. The tires are usually 1-1/8" plus and skinny, you don't want to bog them with glue.

7. Maybe a great project for John H, comm is better than Pittman.

8. None of this is very authoritative but I do have some old drag cars that I haven't run in years. On modern voltages they will run under 2 seconds.

#4

Posted 22 July 2013 - 09:41 PM

It is in fact marked 6 volt. BAD Racing has posted on Bracket 500 that the 18 lam armatures meter about 1.1 ohms. Good start both of you and thanks for the help with this.

Will sliding the arm out of her kill the Alnico? I've heard rumor to that effect.

Must be all grunt and no revs to pull that sort of gearing on a tire that tall but in the ballpark of what I thought it might be just on the few I've seen in person. Dallas Booth had or has a few of the old alloy rails and at one time was trying to get interest in reviving some sort of outing for them.

Don't stop now, just getting interesting.

So hard a judge they hope never to meet as themselves.

#5

Posted 22 July 2013 - 11:20 PM

Will sliding the arm out of her kill the Alnico? I've heard rumor to that effect.

Yes, it will need to be rezapped. It probably should be even if you don't pull the arm out.

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#6

Posted 23 July 2013 - 07:09 AM

So hard a judge they hope never to meet as themselves.

#7

Posted 23 July 2013 - 09:36 AM

Maybe I need to dig the cars out and run them??? I wish 36v was an option!!! The Kemtrons are still around and run very well, some of them have Ram arms also.

#9

Posted 23 July 2013 - 10:37 AM

Hi Marty,

Here's a new RAM 850:

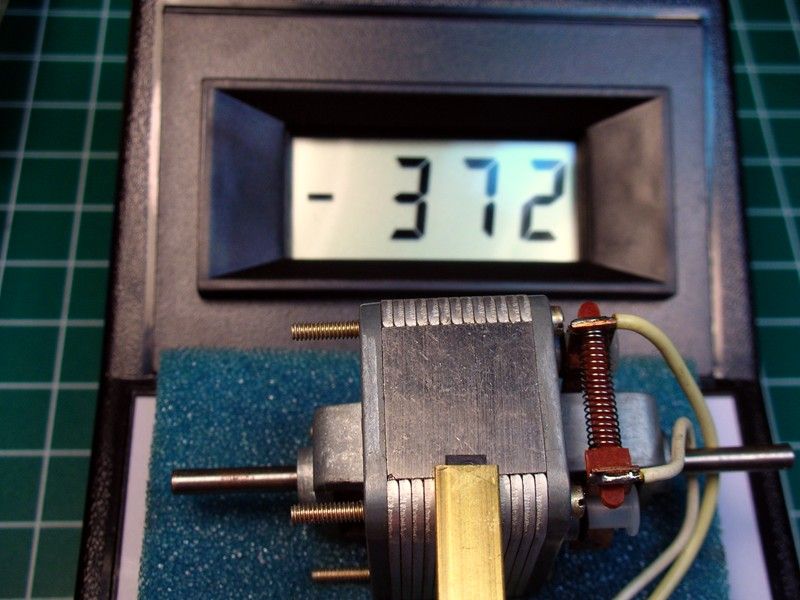

Here's it's magnet strength (gauss) right out of the 40+ year old box:

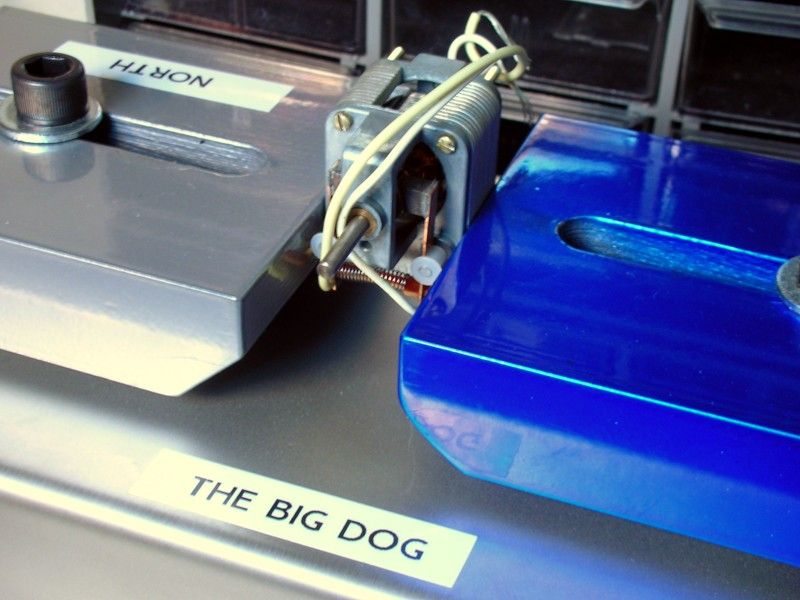

Into the "Big Dog" it goes for a good ZAP!

Ah....now it's happy:

And if you I had removed the magnet it have been even more dramatic.

Here's a link to a thread you might find interesting:

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#10

Posted 23 July 2013 - 10:56 AM

#11

Posted 23 July 2013 - 12:57 PM

1) Magnetic material is mostly Alnico V (Alnico five).

2) Armature wind is voltage rating dependent and is done THREE poles at a time therefore the arms are very much out of balance. Rebalance and cut the comm. The wires are welded to the RAM com where Pittmans were soldered and the RAM coms are similar to the improved Muras in that they are molded and the Pittmans were nylon capped and tended to melt and explode.

3) Gearing = wattage available (originally run on battery-powered dragstrips and homemade and commercial Hillclimbs).

4) Ram engineering made the best brushes... if you look at the brush itself it is swaged high copper content brush and thru Ram Eng Parts a high silver content competition brush in a rectangle was available where as the Pittmans were round , low temp soldered, high carbon pucks with a small single stud (limited wattage and would melt).

5) Lighten up the end plates and rezap mags often. When you get good you can make one brush arm pivot longer and one pivot shorter to advance the arm.

Shakey

The arms work well with high power Mabuchi mags in a can motor as the timing is the same; just drill the bearings for 1/8 inch shaft and soak in oil.

#12

Posted 23 July 2013 - 04:41 PM

Also look for the Ram 857 models. Basic same motor except it used more, thinner laminations on the magnet stack - and (hopefully) more magnetic flux to the armature. It is what I used in the 1960's 36 volt drags.......

- George Blaha likes this

Larry D. Kelley, MA

retired raceway owner... Raceworld/Ramcat Raceways

racing around Chicago-land

Diode/Omni repair specialist

USRA 2023 member # 2322

IRRA,/Sano/R4 veteran, Flat track racer/MFTS

Host 2006 Formula 2000 & ISRA/USA Nats

Great Lakes Slot Car Club (1/32) member

65+ year pin Racing rail/slot cars in America

#13

Posted 23 July 2013 - 05:50 PM

hey ramcatlarry,

Your thinner lams theory I could not test then but now there are tools to test with. I have only had couple of 3 volt arms but found that by that time of availability the quality control was lacking and some of the arms were wound "loose". But the Rams were better than anything else. Graupner tires expanded like the real nhra fuelie tires but there were no wheelie bars on slot drag cars in the 60's. The magwinders were the most fun at 36 volts from the truck batteries into a silk surplus chute.

George Shakey Blaha

#14

Posted 23 July 2013 - 09:29 PM

Good info. I read the link Rick. I see what ya all mean. Interesting George. Three poles at a time eh. Anyone got an arm out of one of these that could tell me the basic dimensions. Stack OD and Length and OAL? Com diameter? Looks like I came to the right place then. Cool. Oh, welded com I guess means no rewind, RATS.

Dok, thanks for posting the picture.

- George Blaha likes this

So hard a judge they hope never to meet as themselves.

#15

Posted 24 July 2013 - 12:43 PM

hey marty,

I have a arm out and will try to answer some of your dimensional questions later today or early tomorrow.

George

#16

Posted 24 July 2013 - 01:56 PM

The fuel dragster class cars all used Ram 850 or 857 motors with 6 volt 1/2 ohm arms in special hand-made magnesium frames, using German tires, Corben part #600D. The gearing varies from 2.8 to 3.4 to 1 with Weldum gears used exclusively. The bodies are generally .010 aluminum with Speedway front wheels.

These cars were basically in the 1 to 1.1 et range.

Gene shows his record holding unlimited car at 0.93. The motor has a full ring ceramic magnet with a Ram arm. Later in the article it explains the ring magnet comes from a late model Chrysler windshield washer motor, not the wiper motor.

11/6/54-2/13/18

Requiescat in Pace

#17

Posted 24 July 2013 - 02:17 PM

Maybe we need a proxy race to sort these out!!! No drivers, no glue, just a clean track and a toggle switch and what ever power is available, more being better.

#18

Posted 24 July 2013 - 02:31 PM

Wish I had my old mag rail yet...among the missing pre 1970. Not sure if the one inch X 12 inch X 1/8" magnesium can even be bought in the modern age where magnesium is a controlled bomb compound part......

Larry D. Kelley, MA

retired raceway owner... Raceworld/Ramcat Raceways

racing around Chicago-land

Diode/Omni repair specialist

USRA 2023 member # 2322

IRRA,/Sano/R4 veteran, Flat track racer/MFTS

Host 2006 Formula 2000 & ISRA/USA Nats

Great Lakes Slot Car Club (1/32) member

65+ year pin Racing rail/slot cars in America

#19

Posted 24 July 2013 - 04:06 PM

hey marty,

I have a arm out and will try to answer some of your dimensional questions later today or early tomorrow.

George

That would be nice George. BTW, decades ago I went to school with someone with the last name Blaha. Never heard it since.

So hard a judge they hope never to meet as themselves.

#20

Posted 24 July 2013 - 04:10 PM

Wish I had my old mag rail yet...among the missing pre 1970. Not sure if the one inch X 12 inch X 1/8" magnesium can even be bought in the modern age where magnesium is a controlled bomb compound part......

I tried to source some about a year ago and thought I'd asked for a ![]() . NZMark on Bracket 500 build a rail using an alloy chassis as a pattern from carbon fiber sheet.

. NZMark on Bracket 500 build a rail using an alloy chassis as a pattern from carbon fiber sheet.

So hard a judge they hope never to meet as themselves.