Cox? Motor ID

#1

Posted 09 August 2013 - 07:12 PM

Bob Israelite

#2

Posted 09 August 2013 - 07:29 PM

Don't know the exact model # but i'm pretty sure it's the "hotter" wind motor Cox did for the Cucaracha that was even hotter when it over heated , think remember hearing PdL mention it had big problems with bearings failing ...

#3

Posted 09 August 2013 - 07:39 PM

That's a Cox Super NASCAR motor that did have severe problems with the can bearing. Motor was in the Super Cuk or sold separate. Balanced but I don't remember the wind. I don't remember what caused the can bearing to seize but I suppose a ball bearing would fix the problem. Not many at our track but the wire usually did burn when the bearing went out.

About a $7 motor that didn't compare with the Champion or Muras.

11/6/54-2/13/18

Requiescat in Pace

#4

Posted 09 August 2013 - 07:42 PM

"The Super Cuc used a "Super NASCAR" motor that had no vent holes in the can, but most failed as the gimball-type can bearing was of poor quality and the armature eventually fouled the magnets while the gears self destroyed, so retailers changed the motors under warranty for the regular NASCAR motor and most Super Cucs found today have that motor."

From a post by Dokk on SCI

- Gator Bob likes this

Steve King

#5

Posted 09 August 2013 - 08:08 PM

Wow, thanks... I never saw one of those totally 'closed can' Super NASCAR motors.

The pictures at the SCI link didn't show for me.

So the chrome can, oval hole - both sides - balanced arm, FT16D is it the Cox NASCAR from Hong Kong ?

... put in the later non-super Cucs and warranty cars.

Was it the same arm spec as in the Super NASCAR? Were they faster but shorter lived then the NASCAR?

Bob Israelite

#6

Posted 09 August 2013 - 08:37 PM

I don't think the regular NASCAR motor was balanced unless it was a later release. Oval holed with nice magnets and it was built in Hong Kong. A reasonable priced $3 motor that was a real good match in a well tuned Cuk. About 1 in 50 of these motors was a fireball and would easily outrun a stock 26D or oval holed Mabuchi 16DBB.

I don't remember seeing a Super NASCAR arm. Our track owner gave a customer an hour of track time with each new car. The Supers expired in that hour and the track owner, Lou, replaced the motor and sent the Super back to Cox.

11/6/54-2/13/18

Requiescat in Pace

#7

Posted 09 August 2013 - 08:39 PM

From what I've read here, over the years...(I think I might have actually learned something? Dokk will come in and correct our homework ![]() ) the "NASCAR" motor, with 2 vent holes was made in Hong Kong (same as the no holes version) by Cox International...it has the same endbell (hi Bob) as the no holes can.

) the "NASCAR" motor, with 2 vent holes was made in Hong Kong (same as the no holes version) by Cox International...it has the same endbell (hi Bob) as the no holes can.

The Cox International can's Brass gimbal bearing holder says COX on it not Mabuchi...and the can's magnet retaining tabs are of a slightly different shape than the Mabuchi's (sort of) rectangular shape.

I don't think the Mabuchi was ever called a NASCAR motor?

I have one of each NASCAR and Super NASCAR Cox International motors, and the arms look to be of the same wind, but it's kind of hard to tell for sure? Looks like maybe 30 ga. wire, and not quite as much as a typical Mabuchi of the same time frame. The stack lams look like they might have a different finish on them too...slightly smoother, and not exactly the same gray color as the typical Mabuchi stack lams.

Tom Hemmes

Insert witty phrase here...

#9

Posted 09 August 2013 - 08:45 PM

4759... Got it. ![]()

Steve King

#10

Posted 09 August 2013 - 08:56 PM

Roger Wilco!

Philippe de Lespinay

#11

Posted 09 August 2013 - 11:02 PM

I've got six of the regular NASCAR motors and none of them have a balancing mark on the stacks.

If the regular 16D was balanced it would have had to been by adding weight like some Falcon motors did.

And Dokk, finish the book, save yourself some explaining! ![]() Well, actually a lot of explaining. A whole lot over the last 12 years!

Well, actually a lot of explaining. A whole lot over the last 12 years!

11/6/54-2/13/18

Requiescat in Pace

#12

Posted 10 August 2013 - 05:23 AM

The # 3600 I have is drill balanced.

"Cox - Made in Hong Kong" on the brass bushing carrier.

Bob Israelite

#13

Posted 10 August 2013 - 06:05 AM

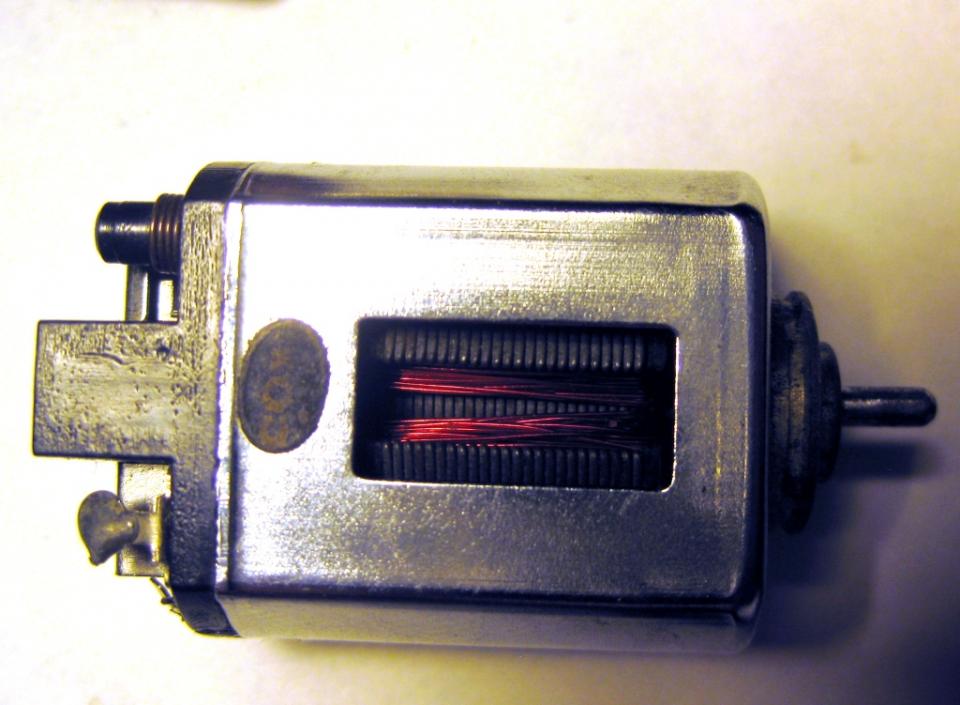

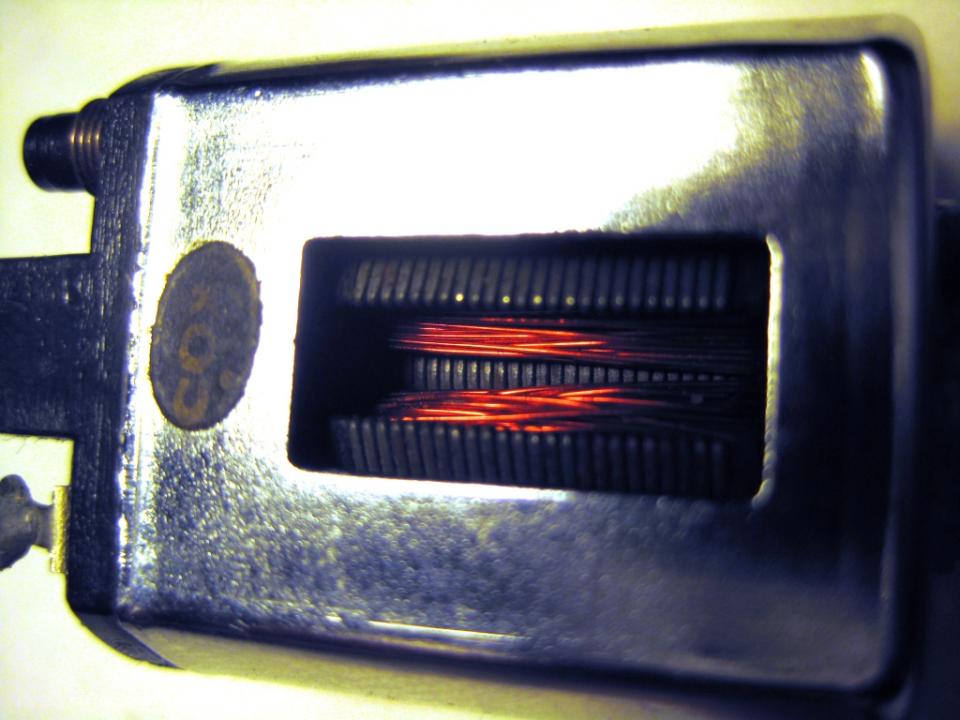

I happened to have two 16D size Super Nascar motors open and awaiting refurbishment, plus another that was still closed. Here are the arms: all with original windings (not sure that's 30, maybe 31?). Two unbalanced, one balanced, but looks more like a home-made job to me...

The one regular Nascar I have in that same box is unbalanced, but can't swear it's stock (and it's a white endbell version).

Interesting thing on the Super Nascar setup is that there are also top and bottom magnet shims, besides the two magnet springs, even tho the case is solid, without holes.

Don

#14

Posted 10 August 2013 - 10:58 AM

Don,

They were not really "balanced" as in dynamic balancing. The company merely drilled a hole in the heavier pole on a static basis. The first NASCAR motors were wound and left alone. Sometimes in 1967, a decision was made to "cosmetically" balance the armatures because of the perception that a hole in a pole made them more attractive to young buyers.

In 1968, the Lola T70 had the large 3500 motor of which a pole was ground off to provide some balancing. Cosmetic or real? Hard to say until someone puts an arm on a set or razor blades...

In any case, while the windings were a bit more radical that the corresponding Mabuchi motors, the quality and reliability of the Cox motors was never as good as their Japanese brethren. The same applies to the Johnson motors used by Russkit: faster, but quick hand grenades compared to the Mabuchi FT16D.

The main failure of all of these were the solder joints at the comm. When hot, they melted and caused heat havoc.

Philippe de Lespinay

#15

Posted 10 August 2013 - 11:04 AM

Oui, mais...

The two arms on the left, both from Super Nascar motors, don't have any balancing holes at all... Maybe they just didn't bother sometimes - after all, there

was no way to see the arm!

On the Testor or Pactra hemi type motors that are statically balanced, you can see the very neat single balancing hole, but not on these...

Don

#16

Posted 10 August 2013 - 11:11 AM

Don,

From what I have been able to gather, all NASCAR and Super NASCAR from introduction time were not "balanced", while all made after 1968 were. So you can have some either way... I have taken some apart and some do, some do not.

The Igarashi "balancing" of the Hemi motors was strictly cosmetic and I have proven to myself several times that it was not "real" by setting their arms on blades and the arms always stopped at the same place, with the hole irrelevant in the process.

The REWOUND motors by Pactra (only the large "X98" ones since they never bothered to process the smaller "X88" units) did have better balancing and the arm at least on static, is fairly well balanced.

Philippe de Lespinay

#17

Posted 10 August 2013 - 03:46 PM

Thats why I even sent my new arms too Thorpe too be Balanced. The new Mura's were not even correct. Please correct me if I am wrong P.

#18

Posted 10 August 2013 - 03:47 PM

Thanks for the clarification Philippe - does the balancing hole on mine look at all like the factory one?

Just disassembled one and strangely enough it also had shims behind the magnets, besides the ones on top and bottom... strange for a factory motor!

Don

#19

Posted 10 August 2013 - 05:12 PM

Don,

My pleasure. Yes, it is factory. As far as the shims, I don't think so, I have never seen any like that. If you can send a picture of the shims we can see if they are an amateur job or factory built.

Philippe de Lespinay

#21

Posted 11 August 2013 - 01:38 AM

Bob,

You probably know but for the ones who have never seen them, the Cox oval hole can above is fitted with Champion "broken" Arco 33 magnets. Apparent give away is the large clips.

The bottom motor is a standard Mabuchi built Cox motor that had 110 turns of 34 wire from the factory. As seen in the photo it appears to be about 25 or 30t. of 30. Way too much "empty space" between the windings. With stock magnets that motor would last about two minutes and be quite slow. 60 of 30 was about as hot as stock magnets could support and live. With Arcos around 45 of 26 but with a good endbell. 45 of 26 fills a stack almost full, as a 517 arm.

11/6/54-2/13/18

Requiescat in Pace

#23

Posted 11 August 2013 - 09:32 AM

Yep, those do not look like amateur jobs. I am not sure of when they started that... Don, is the arm "balanced" or not?

Philippe de Lespinay

#24

Posted 11 August 2013 - 10:57 AM

...Just took apart a second Super Nascar, and it's got the magnet shims too - so I guess it's factory!

Mine have the shims too Don ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#25

Posted 11 August 2013 - 11:01 AM

Don, is the arm "balanced" or not?

Not this one Philippe - you can see in the photo above, 2 out of 3 were unbalanced and the other had two balancing holes, very similar to what Bob shows above...

Just soldered in new bearings on two of these cans, and am trying to figure out how to save a third "under construction" - often, I just center the arm and flow some epoxy around the floating bearing - a quick, easy fix!

Don