I was looking over the Pro Slot Gear Chart.

Does anyone know the formula for calculating the gear ratio using tire diameter please?

Yes, I'm aware that is what this chart is for but the lowest tooth pinion charted is a 25T. I have a few 24T pinions and would like to figure out what the gear ratios would be using certain diameter tires.

Thank you.

Ernie

How to calculate gear ratios with tire diameter

#1

Posted 27 August 2013 - 12:25 PM

#2

Posted 27 August 2013 - 12:54 PM

Ernie,

The formula is this:

(axle # / pinion #) x (1 / tire dia.) = gear ratio

where

axle # = tooth count of spur or crown gear

pinion # = tooth count of pinion

tire dia. = decimal diameter of tire

Or to put it in words, simply divide the gear ratio by the decimal tire diameter.

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

#3

Posted 27 August 2013 - 01:55 PM

IIRC, Monty Ohren used to refer to this as the drive ratio.

I intend to live forever! So far, so good.

#4

Posted 27 August 2013 - 02:12 PM

I doubt you are using 24 and 25 tooth pinions! The pinion goes on the motor, not on the axle - that's either a crown gear (Inline) or a spur gear (Anglewinder or sidewinder).

Greg's formula describes how the Pro Slot chart was calculated, but it's not actually a "gear ratio", it's something in between a gear ratio and a "roll-out", because it omits the circumference calculation that is contained in roll-out (the distance travelled by the car for one revolution of the motor).

The major use of this type of chart is to determine what gears to use when changing tire sizes so as to retain the same roll-out number.

#5

Posted 27 August 2013 - 02:16 PM

Paul Wolcott

#6

Posted 27 August 2013 - 02:20 PM

Considering tire size as part of gear ratio is a rather useless approach IMO, as most racing is done in relation to a minimum tire size which is almost always used, or at least approached.

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

#7

Posted 27 August 2013 - 02:20 PM

Useful note I derived from the Pro Slot gear chart:

.020 difference in tire diameter = approx 1 axle gear tooth

#8

Posted 27 August 2013 - 02:33 PM

Dennis' inference is spot-on.

Thanks!

I may not be a rocket scientist any more, and I did not stay at a Holiday Inn Express last night, does a Marriott Courtyard count?

(a historic one at that - Blackstone Hotel, (Fort Worth, Texas))

#9

Posted 27 August 2013 - 04:03 PM

Dennis--you've ALWAYS been a FAST slot racer---so that qualifies in my book as a good Rocket Scientist!!! ![]()

![]()

![]()

#10

Posted 27 August 2013 - 04:07 PM

Good catch! I meant 24t "crown" gear not PINION!

So! I have a .725" OD tire that I want to use. I want to gear my inline chassis for a blue King track using a "boxer" type motor (one of those long cans) using a 24t CROWN gear; using a 3:1-3:3 gearing, shall I presume an 8t pinion will work considering...

Considering tire size as part of gear ratio is a rather useless approach IMO, as most racing is done in relation to a minimum tire size which is almost always used, or at least approached.

I understand that an 8t pinion with a 24T crown yields a 3:1 gear ratio without considering tire diameter. My question is then, how do I approach gearing when it comes to employing a certain tire OD? How can tire OD not have any value when one is wanting to employ different sizes of tire?

I'm not referring to "minimum tire size" in regards to certain classes of racing.

Help me please!! I'm confused.

Ernie

#11

Posted 27 August 2013 - 04:20 PM

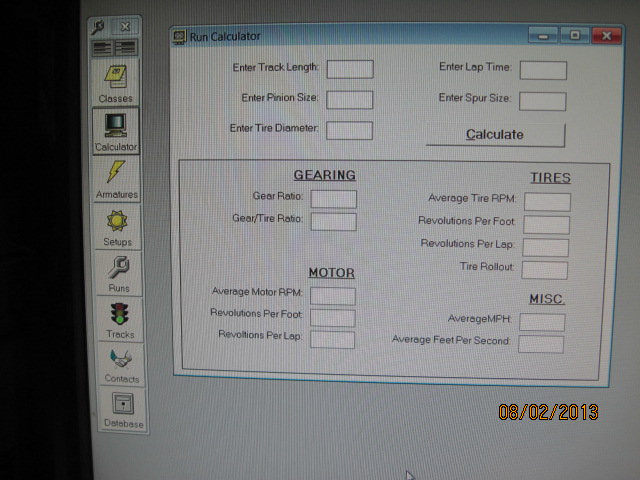

This is the way you would use the Pro Slot chart:

Let's say you find someone who is running well with the motor and car you want to use. He is running .750" rear tires and is geared 8/26.

On the Pro Slot chart, you enter .750", click on "calculate" and look at the intersection of 8 and 26. That gives a "drive ratio" of 4.33.

Let's say you only have .790" tires and you don't want to cut them down. So you enter .790" in the chart and go looking for a number somewhere that is nearest to the 4.33 your buddy is using.

The closest you will find is 4.27 using 8/27, but if you could change pitch to a 64DP for example, you might use a 10/34 for a 4.30 drive ratio, or 12/41 for a 4.32 drive ratio.

Confused now?

If not, let me try to explain entropy... ![]()

#12

Posted 27 August 2013 - 04:24 PM

But how to figure if the right rear is 3 inches more around than the left rear on an oval track?

Few people know that when a 1:1 slows down after a long run on the tires is mostly a loss of grip but also because the drive tires have worn to a smaller diameter and lowered the gear ratio and the car loses speed on the straights.

11/6/54-2/13/18

Requiescat in Pace

#13

Posted 27 August 2013 - 04:26 PM

I prefer the Roll Out method. (Thinking out loud) The tire size comes into play if you are running multiple classes/cars with similar motors or want to calculate how much to change the gear ratio. So if I am going back to a track with some history in my toolbox, I should be real close even using .720" dia tires while referencing the .800" dia tires. We might be running three classes with different tire sizes at GSRA. so this can be a big help.

One advantage of Roll Out is being able to calculate the motor revolutions for a given length straight/full throttle section. This number should be pretty close regardless of how long the straight/full throttle section is assuming the motor is revving out. If the lead-on is slow or fast needs to be a consideration as well as it will effect the max RPM of the motor. Some testing is required to quantify a base line to see if the motor stops pulling "X" number feet before the end of the run. If you are running out of motor 10 feet from the end, you know your Roll Out needs to be 120 inches farther for the same motor revs.

I do agree if one is running the same/similar tracks with similar tire sizes it is easier to just talk about the ratio being used and not overcomplicate things which I tend to do.

Roll Out = IPR (Inches Per Revolution)

D= Tire Diameter

TT= 3.14159

R= Ratio

L= Full Throttle Length in Inches

MR= Motor Revs

IPR= D*TT / R

R= D*TT / IPR

D= IPR*R / TT

MR= L / IPR

IPR= L / MR

As an exercise, lets say you have a full throttle run of 40ft or 480 inches. The car seems to go flat at about 30 ft or 360 inches. Now lets assume your IPR = D*TT / R = .800*3.14159 / 3.0 = .837". The motor has turned 360" / .837" = 430 revs. So you want 430 revs with the additional 120 inches added in. This gives us IPR = L / MR = 480" / 430 revs = 1.116"/Revs. Now we have R= D*TT / IPR= .800*3.14159 / 1.116 = 2.25:1.

Of course this assumes the motor will rev out with the additional IPR without going up in smoke so it should be tested. While we are tuning for the straight in this excercise, you might have to throw away some of the full throttle run for better driveability through the rest of the course. Either way, you will find the number (IPR) that works and can apply that to your other cars.

Mark Horne

SERG - www.slotcarenduro.club

"Racing is life... everything else is just waiting." Steve McQueen - LeMans

There are only two things in life that make me feel alive. Racing is one of them.

#14

Posted 27 August 2013 - 04:28 PM

Ernie,

Here's my take on what you're asking.

Gearing a slot car for best lap times is essentially a trial and error process. You can guess, based on experience, what gear ratio will accomplish the best lap times with a particular tire diameter, but to know what gear ratio actually does result in the lowest lap times requires testing. If someone feels this is incorrect, post away! I'll be listening...

Suppose you have a particular car that has 7/8" (.875") diameter rear tires and through testing you find that the lowest lap times occur with a gear ratio of 9/29 = 3.22:1. Considering the tire diameter, this would be a "drive ratio" (to use the late Monty Ohren's term) of 3.68:1.

And now you wish to change the rear tire diameter to .790" and desire to have the motor "see" the same drive ratio as with the .875" diameter tires. To get as close as you can with the same 9t pinion, your would need to change to a 26t spur (or crown), which with the smaller tire diameter will give a 3.66:1 drive ratio. You could also change to a 10t pinion with a 29t spur or crown and achieve a drive ratio of 3.67:1. And using an 11t pinion combined with a 32t spur or crown will give the same 3.68:1 ratio.

Drive ratios, or as Pro Slot calls them, final drive ratio computations are most useful when moving to a different tire diameter on a car where the optimal gear ratio with a previous tire diameter has already been determined through testing.

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

#15

Posted 27 August 2013 - 04:32 PM

#16

Posted 27 August 2013 - 04:33 PM

And all three replies were essentially correct, too.

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

#17

Posted 27 August 2013 - 05:52 PM

I agree, all three will work. Just have to pick one. ![]()

Mark Horne

SERG - www.slotcarenduro.club

"Racing is life... everything else is just waiting." Steve McQueen - LeMans

There are only two things in life that make me feel alive. Racing is one of them.

#18

Posted 27 August 2013 - 06:03 PM

And all three replies were essentially correct, too.

Don's math is off.

The drive ratio is gear ratio divided by tire size, not multiplied by tire size, if you want to get to the numbers in the Pro Slot chart.

#19

Posted 27 August 2013 - 06:16 PM

- Michael Jr. likes this

Rick Bennardo

"Professional Tinkerer"

scrgeo@comcast.net

R-Geo Products

LIKE my Facebook page for updates, new releases, and sales: Rgeo Slots...

Lead! The easy equalizer...

#20

Posted 27 August 2013 - 06:35 PM

Dennis,

Confused now?

If not, let me try to explain entropy.

The function of thermodynamic variables, no matter how well you explain it, would not help me - LOL!! But "Thank you" for the offer.

I remember growing up, the only mention was of gear ratios. The older guys at the track would tell me to gear something 3 to 1, 3.5 to 1, etc., and never any mention of tire diameter.

So, I guess I'll go back to doing just that. Thank you all for your input. It is appreciated!!

Ernie

#21

Posted 27 August 2013 - 06:37 PM

Don's math is off.

The drive ratio is gear ratio divided by tire size, not multiplied by tire size, if you want to get to the numbers in the Pro Slot chart.

Just checking to see if anyone is paying attention.

Naw, that's not true! ![]() I didn't check my math. It is divide. Pablo caught me on that same thing a couple years ago.

I didn't check my math. It is divide. Pablo caught me on that same thing a couple years ago.

11/6/54-2/13/18

Requiescat in Pace

#23

Posted 27 August 2013 - 09:03 PM

From the Rollout Calculator...

The rollout ratio number given is not actually a ratio. It's a distance. In the example, 0.756" is how far the car will travel with one revolution of the armature.

Only if one assumes no tire slippage, which is not the real-life situation. ![]()

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

#24

Posted 28 August 2013 - 02:09 PM

What I'm interested in is "effective" gear ratio. This is what will be in our Fly Truck Proxy spreadsheet. Here is a link:

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

#25

Posted 01 September 2013 - 06:25 PM

From the Rollout Calculator...

Only if one assumes no tire slippage, which is not the real-life situation.

If you have "slippage" you're just not using enough glue. ![]()

Please! This is supposed to be a happy occasion.

Let's not bicker and argue over who killed who.

- King of Swamp Castle: Monty Python, Holy Grail