Jairus,

After I posted that quick drawing yesterday I realized I had ended up describing something that I wasn't showing. So, given 24 hours I've re-done my drawings so they are more comprehensive.

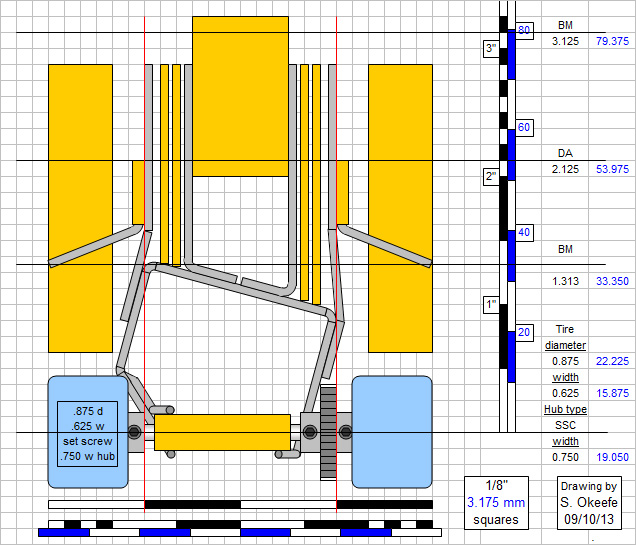

For the wide set main rails (1-5/8" wide center section), here's how far back the rear side pan hinge tubes can be located (this could be considered the "gold standard"):

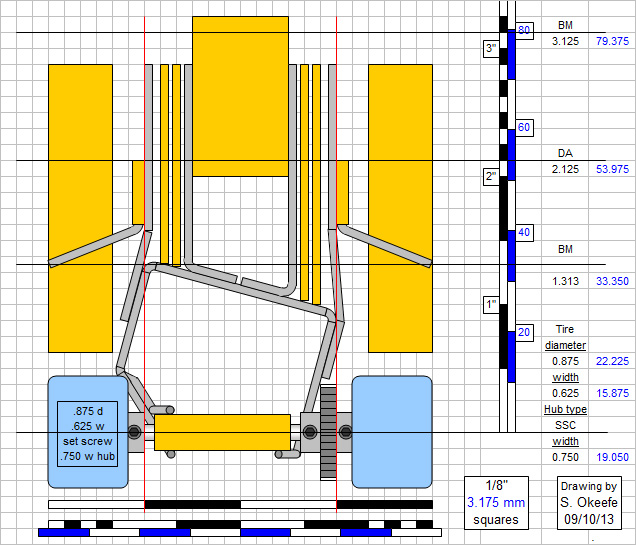

If you crowd the main rails together towards the drop arm (giving you a 1-1/4" wide center section), the rear side pan hinge tubes must be pushed far forward, in this case all the way to the drop arm hinge. This is an extreme example to illustrate my point; I doubt any pro builder would actually construct a chassis this way:

Most builders would (and many did) add extra bends in the outside main rails, jogging them to get that rear side pan hinge mount farther back. Introducing extra bends complicates the build, and the closer together those bends are the harder it is to get them right:

There are of course several other ways to deal with this dilemma. In the wide set example, the rails are spaced at 1/16"; it would be just as easy to space them at 1/32" (or some combination of 1/16" and 1/32"). That way they appear to be close in but the outside rail would be far enough out that the jog required would be much smaller and simpler (simpler is always better) Note in this example, the center section is 1-1/2" wide:

Another way to locate the rails farther out would be to add a space between the drop arm and the inner rail. You couild also use a wider (7/8") drop arm.

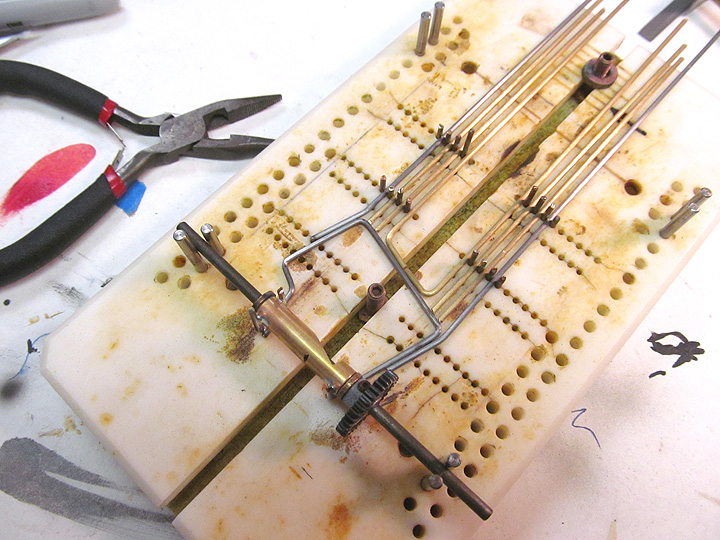

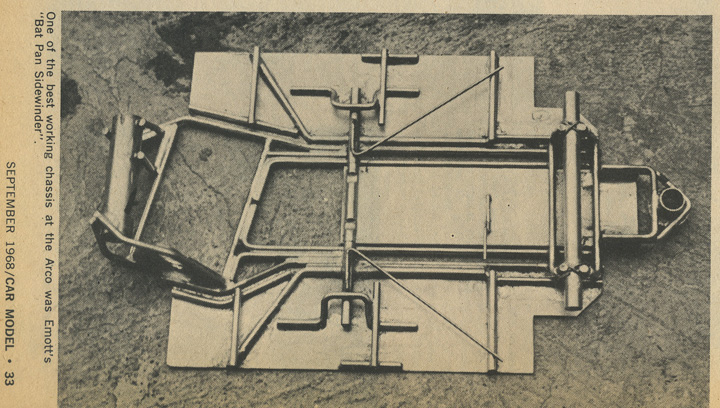

Lastly, you could taper the whole center section back-to-front so that the outside rails remain completely straight from the motor-box to the front axle on both sides (same as the wide set main rail example above), allowing you to locate the side pan hinge tubes anywhere you like (that's what Bob Emott did).

Anyway, all of this is just babble from an old chassis geek.  Hope you find it useful.

Hope you find it useful.

![]()