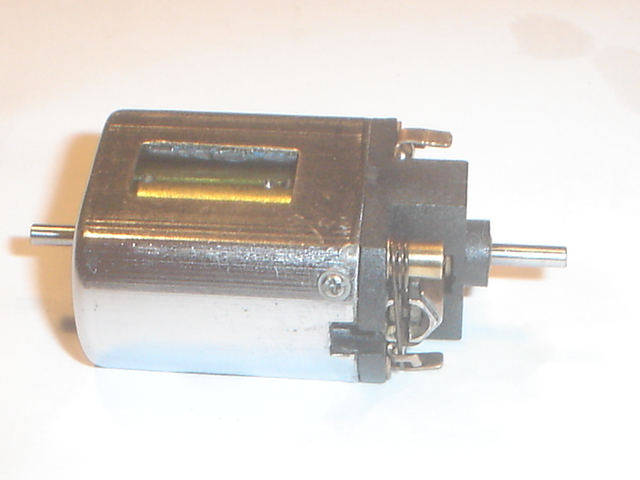

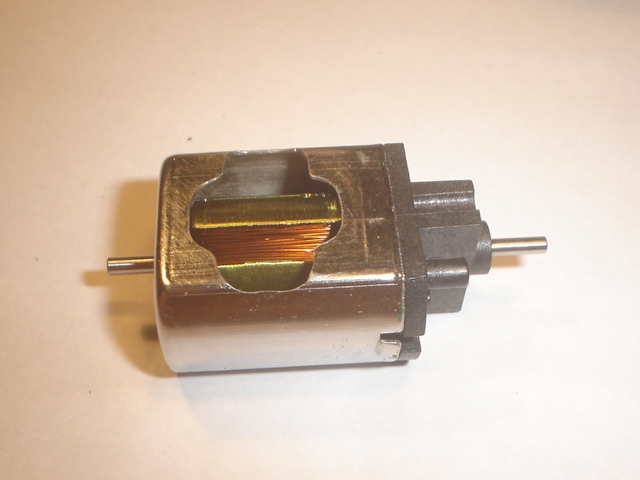

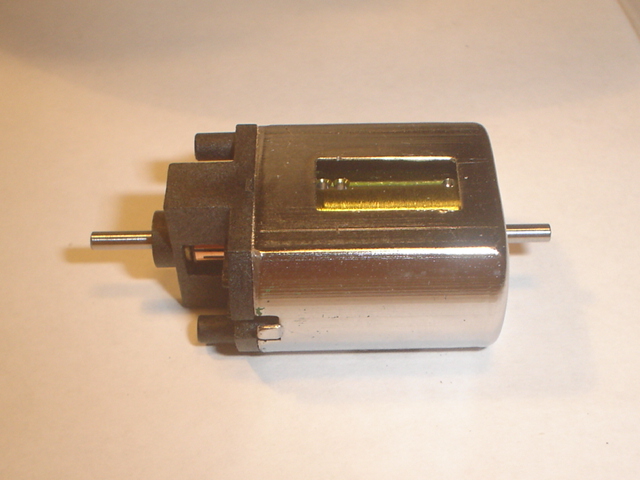

Finished September 2013:

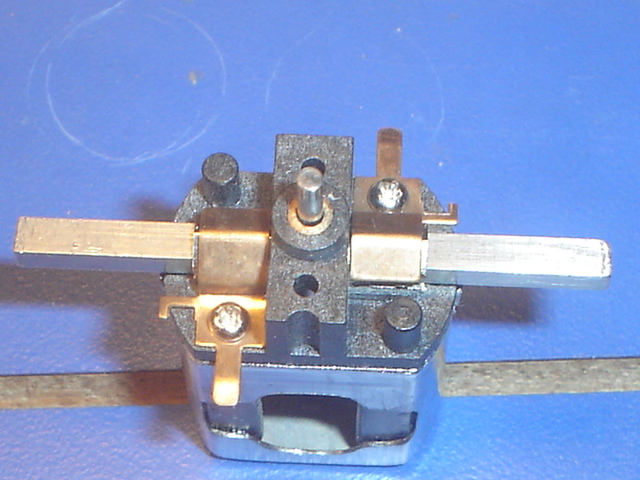

Here's how it all started:

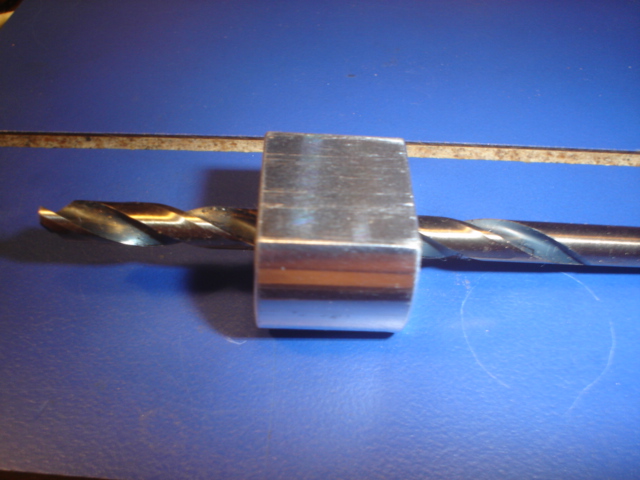

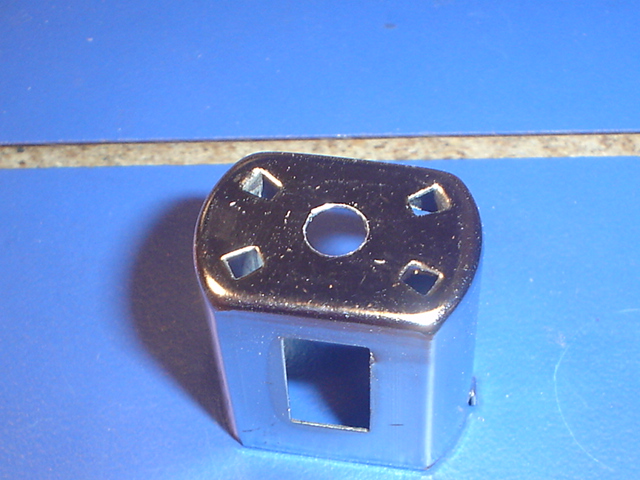

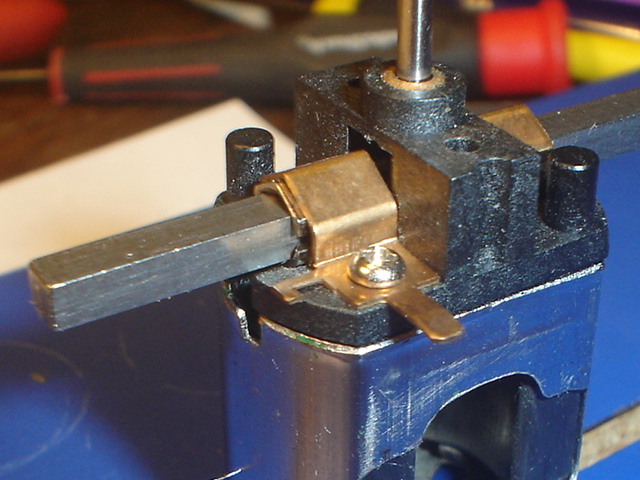

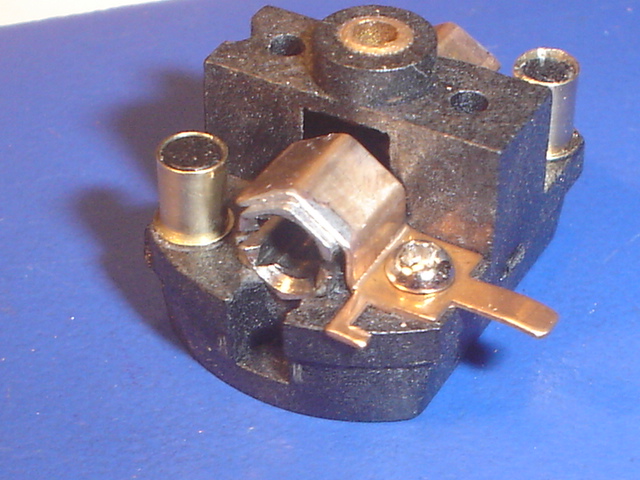

dc-65x built me a new tool for making 5mm ball bearing holes in old vintage cans.

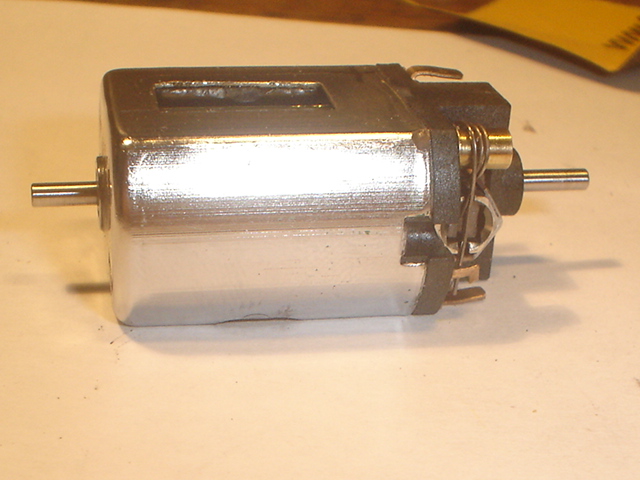

Goat Boy 16D BIT (Bearing Insertion Tool) bored out from 2mm to 5mm to accept a drill bit for a ball bearing hole. It works like a charm.