I watched the Mike Steube/Keith Tanaka video today (third time). ![]()

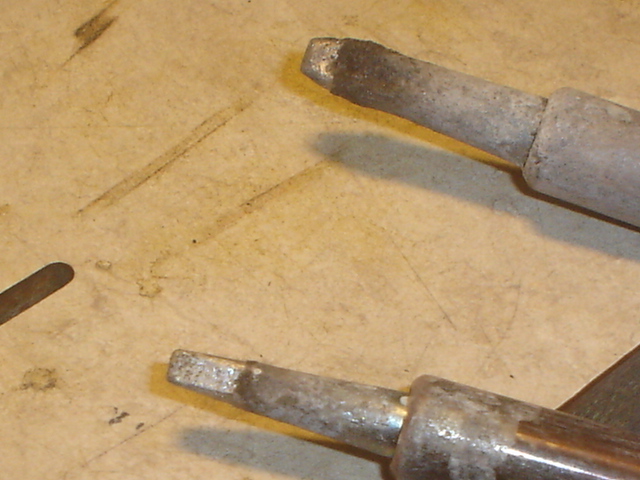

Mike's tips look brand new, clean, and smooth throughout the video. I'm not a newbie, but my tips look like crap compared to Mike's.

I notice his preference for tip cleaning is a sponge. No tip tinner/cleaner, no brass wool.

I know some people prefer a wet sponge, and some prefer brass wool. I have always preferred the brass wool. I tried the sponge once, and for me, it sucked.

How does Mike keep that tip looking like new? He sure applies a lot of acid! Maybe I need to learn the sponge??

Your experience and advice is appreciated. ![]()