Hi all.

Original post came from

HERE. This is the

THREAD I've posted a long

WRITE-UP on Slotforum in the Henley-in-Arde '24 hours of Le Mans' thread.

Here it is:

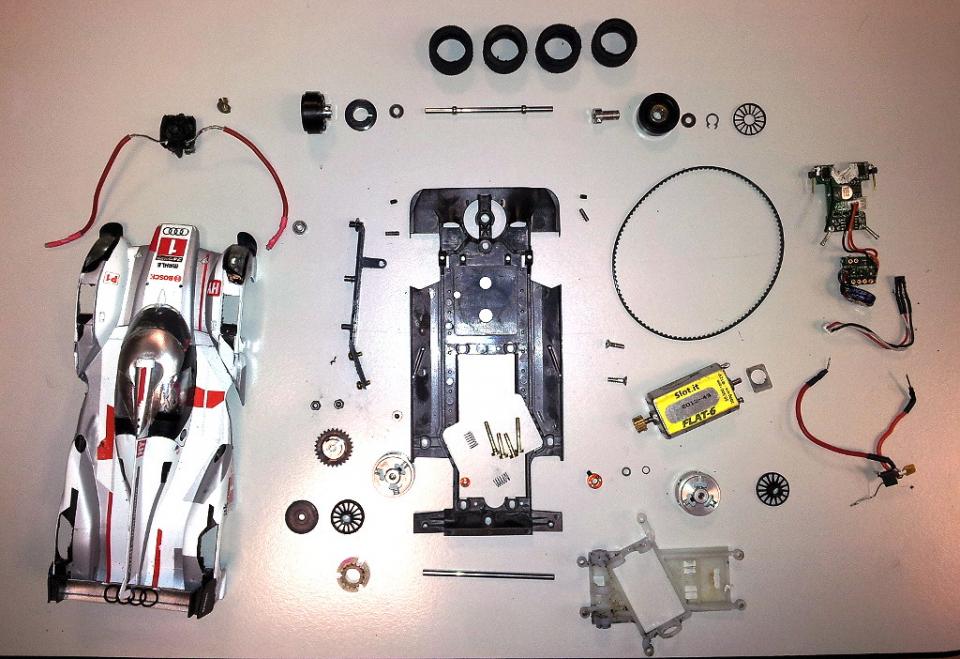

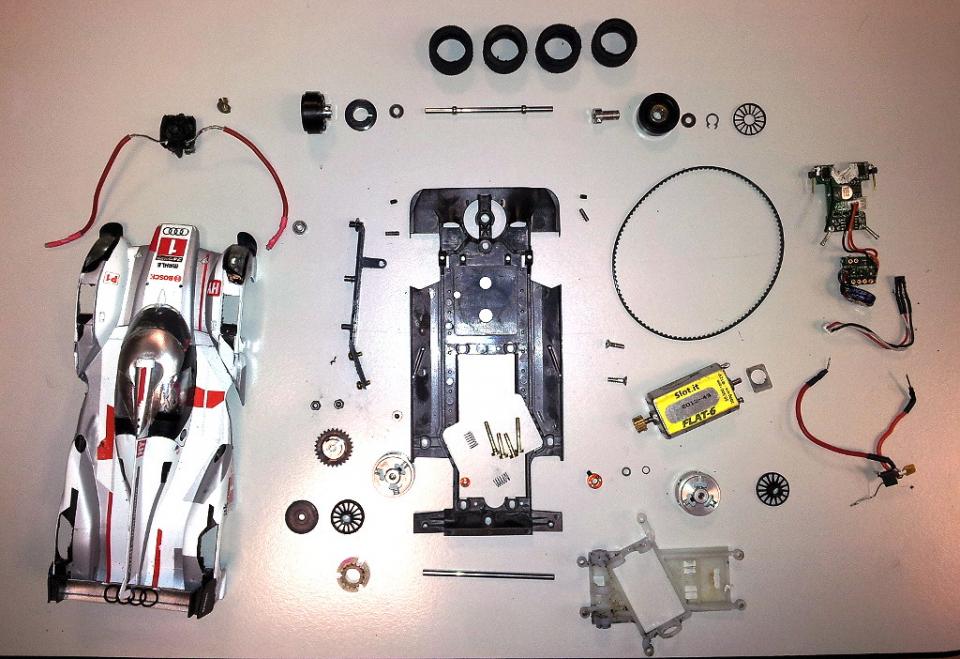

Dissecting the Alien. Anatomy of the Slot.it 4WD Audi R18 etron, on pole position at the "Le Mans 24 hours", Henley in ArdenThe car that BB Slot Reggio Team raced in Henley is a completely new design, representing the Audi R18 etron which won Le Mans in 2013.

The only common part with the production Slot.it R18 is the chassis and the motor mount. Bodywork (long tail 2013 type), cockpit, windows, rear wing, front lights - everything is new and redesigned according to Audi files.

When we decided to start developing the etron versions, the idea of making a 4WD was nothing more than a figment of imagination but the clutched bearings were something I had been playing with ever since I started playing again with slot cars, in 1997: they were tested with success on a SCX Audi IMSA, then on a modified Ninco McLaren F1GTR, and finally on a rally Ford Focus SCX all inline cars. It was a good answer with still no question asked!

Credit where's due the original idea of using unidirectional bearings was suggested to me by my dear friend Oliver Piazzi, a gifted mechanic, in 1997. All the rest is several months worth of my own design, prototyping, sourcing, testing and racing. I must say that this has been one of the most thrilling developments that I've been working on ever since Slot.it began.

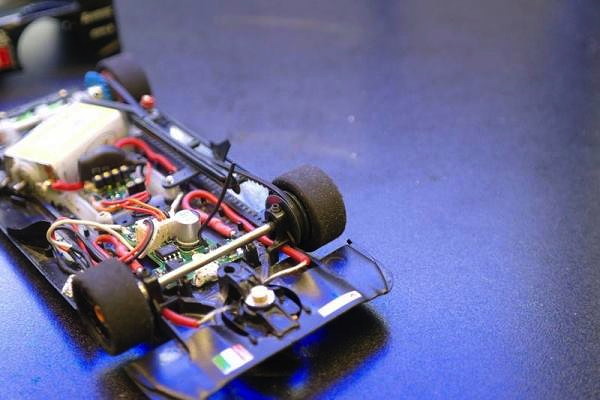

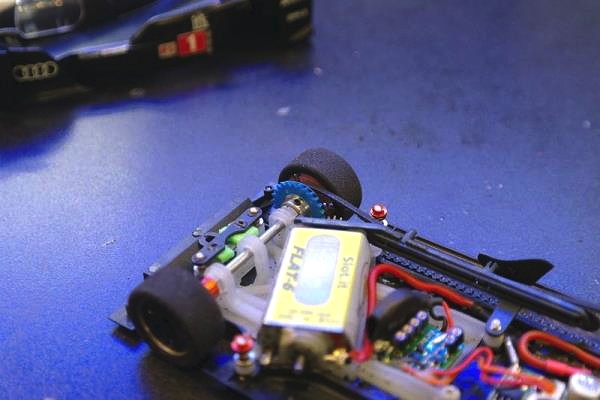

So, going back to when it started, I looked at the 3D CAD drawings of the R18, and I realised that making a real 4WD was not completely impossible. I had to overcome several obstacles, miniaturize all that was needed to fit everything inside the available space, find a way to make a front wheel that could include all the mechanical parts, BBS rim cover included, develop pulley, belt, tensioner, and eventually, when I thought everything was OK, find out that the 2013 body was even lower than the 2012 one, which required a tensioner redesign, and just a few weeks before the Henley race, discover that the rear pulley wouldn't work with short hubs magnesium wheels. After a few more hours of head scratching, a special pulley was designed and prototyped.

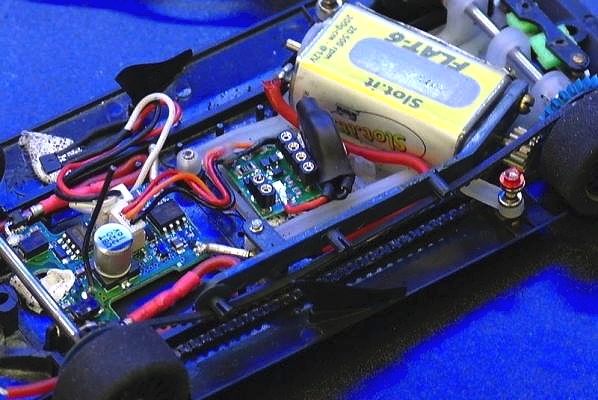

How does the Slot.it 4WD system work? Well, the principle is rather simple: clutched bearings transmit only positive torque, letting the wheel turn freely with almost zero power losses whenever the wheel tries to spin at lower speed than the speed of the shaft it's attached to. For example, this allows the inside front wheel to spin freely while the model turns, overcoming the dreadful understeering of standard 4WD slot cars, and on straights, it reduces front wheels' friction drag to zero, thus reducing power losses to just whatever the toothed belt causes, which is not much. On the other hand, whenever the front wheels can provide any traction, they do.

So what's in the picture? From the top right - a disassembled front wheel (right), exposing the inner hub, the plastic wheel pressed on the bearing, washer, seeger ring to keep it all together, and the OZ rim part. On the other side, the wheel is assembled, but the pulley and inner flange can be seen. Note that to attach the pulley to the hub, the grub screw must be fully inserted tin the hub, the pulley positioned on the hub, and the screw pulled out to enable assembly on the shaft. The grub screw itself keeps the pulley attached to the hub both axially and radially, thus providing the locking mechanism on the hub.

Front shaft is running on two spherical bushings inserted in the front shaft supports (I knew sooner or later I'd have used this feature

).

The tensioner is on the left of the chassis we used a flanged ball bearing in the 24 hours, but in my opinion the standard plastic sleeve (not in the picture) works almost equally well.

The three-lobed plastic part in the bottom of the picture is the special rear pulley, to be used with magnesium rims while with standard aluminium rims, the same front pulley should be used.

Of course, there's a 110 teeth belt, which withstood the 24 hours well.

One of the objectives was to make the system with entirely box stock parts, except for the 4WD specific pieces. So, chassis, motor mount, rear wheels, shafts, are completely standard, and the 4WD system is a compatible bolt-on kit.

For race preparation, we choose front and rear pulleys of 17 and 16 teeth respectively. These models should be run with front pulleys with a number of teeth greater or equal than the rear.

The system's performance exceeded my expectations. From previous testing, it seemed to me that on Ninco track, the 5 grams of added weight and complexity would cancel any of the 4WD benefits. Besides, the car must rest on all four wheels, for the system to make sense. The uneven nature of Ninco track made things worse, and the pickup would loose depth in the groove. Hence, a wooden track pickup with blade shaved to the necessary length was used this radically transformed the performance, for the better.

After 24 hours of real racing, the only major problem was lockup of the front right bearing due to rubber dust that had entered the bearing itself, 30' before the end of the race. This lockup which turned the right front wheel into a standard press on wheel, worsened performance by around 0.5-0.7 per lap. A good after race cleaning returned it to proper running order.

So here it is the car set the fastest lap in qualifying, and led the race for three hours. Not bad for a first outing of such a 'radical' package, that in common wisdom shouldn't even be tried... True, we had Gabriele Cassandra driving, who is in my opinion one of the fastest, gifted drivers one could find, but the 4WD etron performed surprisingly well, nevertheless, until normal race accidents put us out of the fight for the podium.

In all honesty, I don't think we'd have been able to keep the same pace we had for the first three hours, for the whole of the race, but we certainly succeeded in enjoying ourselves, and as the 'father of the Alien', I couldn't hope for a better baptism.