How about just clearcoating the can so you can still see the seams? I've seen a few 1:1 cars/trucks done this way to protect the un-restored appearance... looks cool!

Hi Don,

Yes, there is a thing now where entire cars (!) are powdercoated with clear... obviously when the entire body is perfect! Of course, that means that there's no such thing as "ding repair" for that vehicle... a minor dent means replacing an entire portion of the car's body!

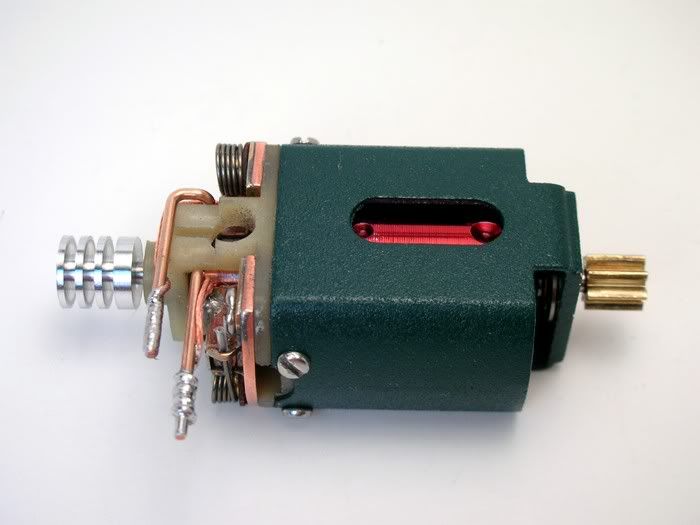

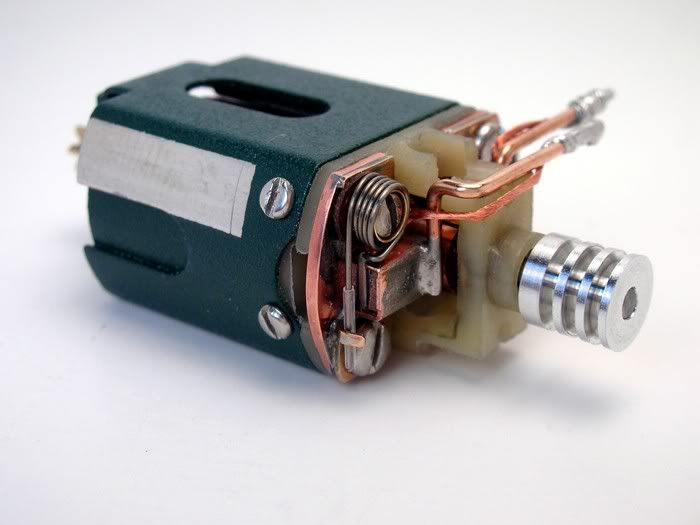

In the case of a slot car motor, the only clearcoats easily available I know of are acrylics, and those will soften at the temperature of a cup of coffee. I could spend some time taking the whole can down in steps to #600 or so with wet/dry paper and then polish it. It's a lot of work, but I have steel chassis I've built and they have stayed rust free after several years in my basement. The smaller scratches and wax residue from the metal polish seem to somewhat protect the metal.

The only real solution to a non-painted "rust-proof" finish I can think of would be to have the can nickle plated... so I don't know. n any case, it really is a piece of work and all these years looking at the thing in it's previously rusted state I had no idea what it might be. Wish I knew who made the thing... or who it might have been made for or really any more information about it.

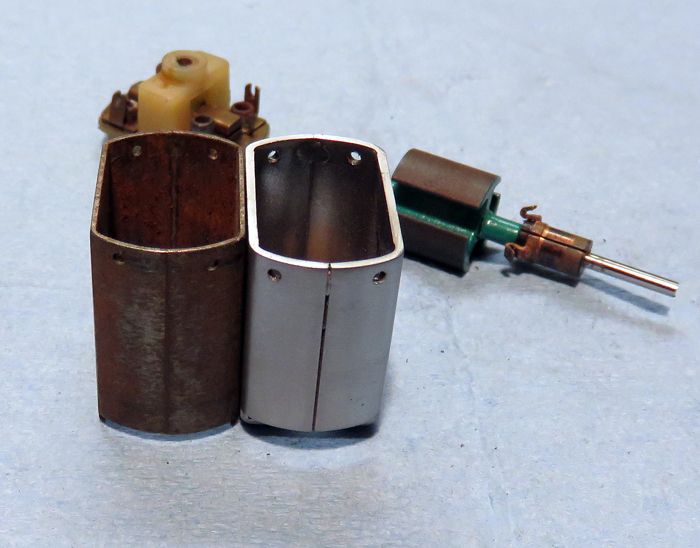

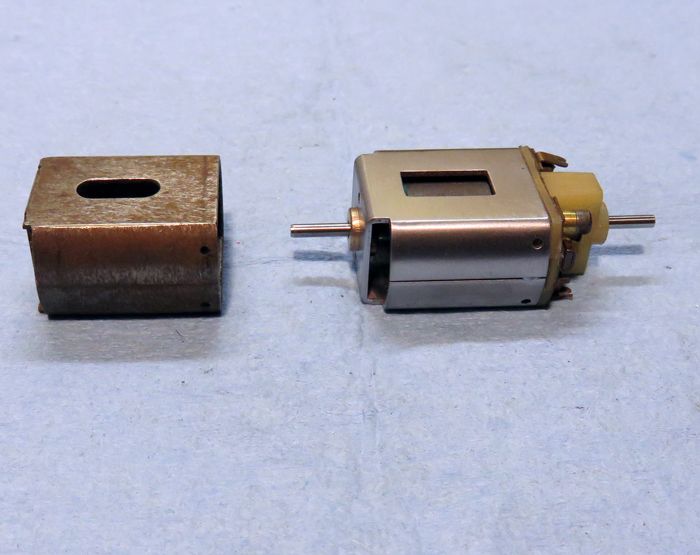

Rick, the can measurements on the outside are:

- 1.017" long

- .614" tall (flat-to-flat)

- .930" wide (curved surface to curved surface)

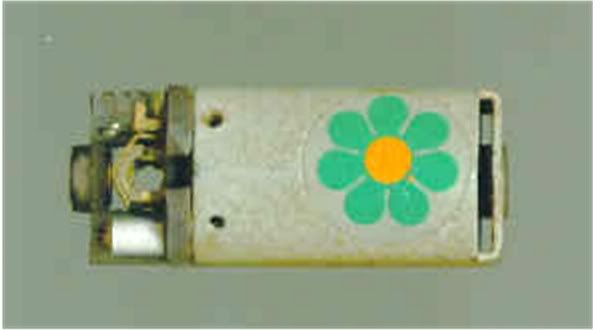

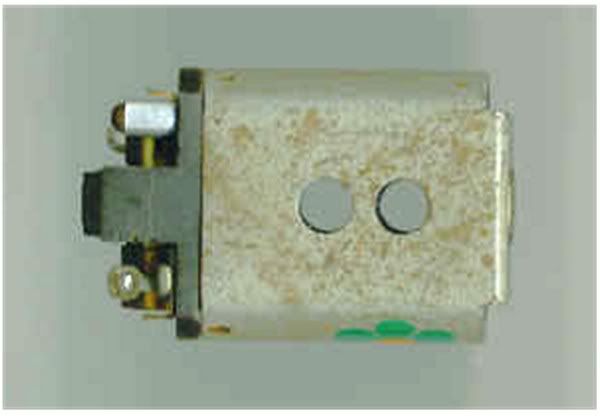

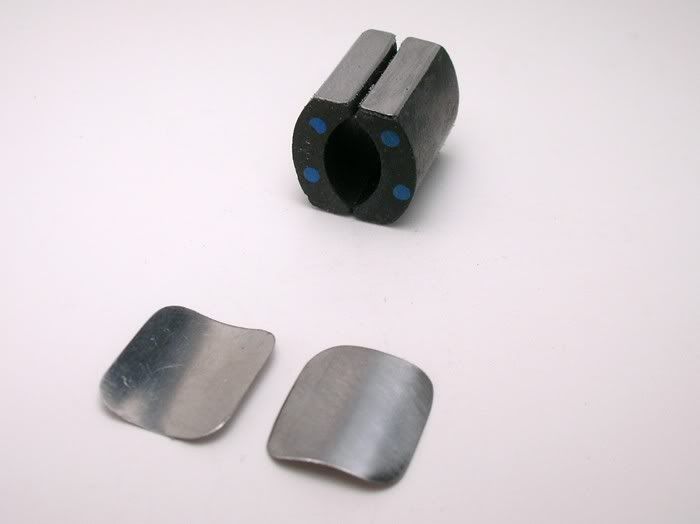

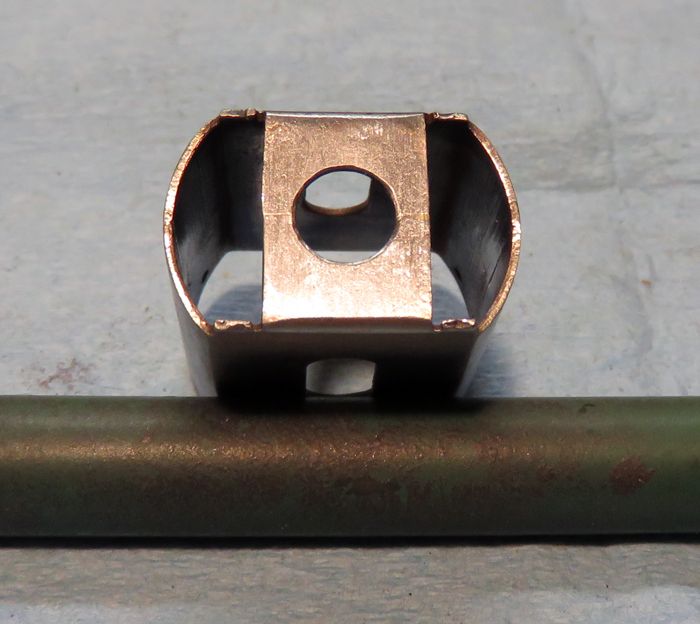

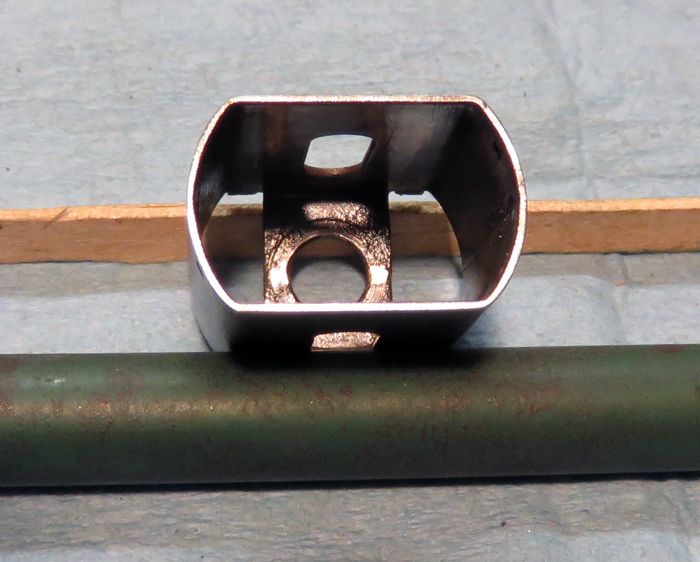

So, while the height is closer to the Associated dimensions you listed, the length and width are closer to the French/Tradeship dimensions, but of course any of those could have easily been changed when modifying the can. The radius sections of the can are very close to a perfect/true radius and, as more and more is "sectioned" from the sides of the "arcs" to remove height, you would wind up with something of a "point" at the side seams if you follow the geometry. To a degree, you could always re-machine the sides on the outside to reform a more perfect arc, but you couldn't go all the way to the flats on the inside with round tooling to do that without either marking the flats or leaving a small area not machined. So, there are still some significant "mysteries" that may never be solved with any certainty.

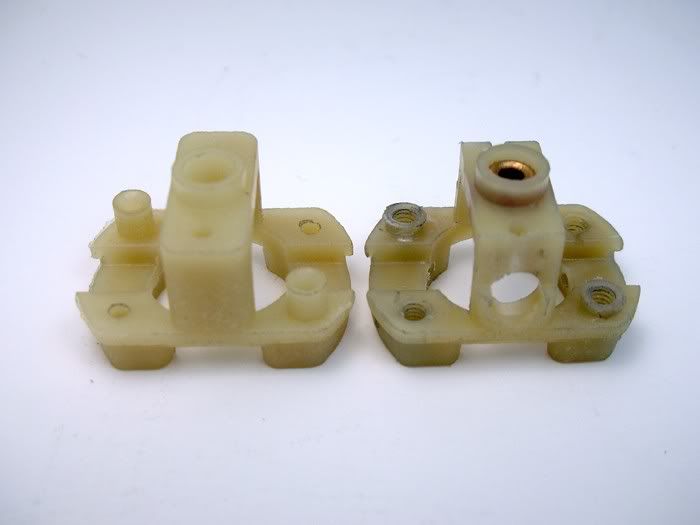

So, I can use the slightly modified "C" motor endbell with a bit of shimming on the curved faces, even though it's most likely not what would be totally appropriate (unless this can was done later as a "what if" project by some very talented builder). The bushing kind of bothers me because it's so honking big. The bushing hole was apparently sized for a .250" x 2MM bushing which is the size of the oddball Champion endbell ones, but those aren't flanged. I have some of the gigantic ones later used (retrofitted?) on the Champion which could always be used as raw stock and turned down to .250" OD on the body and a more appropriate OD at the flange. I'll have to think about all this for a while, but I'm not going to just go "gonzo" on this thing as I usually would and simply dive in.

-john