Here's a second technical tour de force by Ken Irwin, of the Cambridge Model Car Club in Cape Town, South Africa.

Slotblog has published one of Ken's technical tomes before, Making a Tyre Cutter for Donuts, and here's the next one, Blueprinting Slot Car Motors, which is as complete and deep a dissertation on slot car motors as has ever been seen IMO. In MS Word, it is 59 pages long, with 83 images!

Ken has kindly provided a number of other technical treatises that will all eventually be posted here at Slotblog. Thanks to him for sharing his vast experience and knowledge for the betterment of our hobby.

Blueprinting slot car motors

#1

Posted 12 July 2014 - 03:31 PM

- F1fletch likes this

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

#2

Posted 12 July 2014 - 03:47 PM

Blueprinting Slot Car Motors

Warning: this article goes from simple to very complicated and possibly even to outrageous.

Blueprinting means getting the motor to “blueprint” or design condition (and in many cases better).

These motors are mass produced and suffer from a number of “problems” that can be improved upon.

Note: Check your local/national class rules before modifying a motor. There is no point in winning by cheating – or finding yourself disqualified after winning. Scrutineering tends to get more intense the more you win.

The principal problems (in order of importance/likelihood):

1) Poor alignments of armature to the motor’s magnetic field (the armature is hard up against one end or the other).

2) Loose magnets.

3) Loose bearing bushes.

4) Poor brush alignment.

5) Imperfectly balanced armature.

6) Improperly made armature – no lashing to secure wires.

7) Commutator out of true.

8) Brush spring set-up.

9) “Cheap” brushes and springs.

10) Relatively “soft” motor shafts – which can bend in a crash.

The above list is “generic” and is applicable to all motors to some degree or another. These problems are not specifically applicable to the Pro Slot SpeedFX (shown in photos) which is generally a fine motor.

The following blueprinting was performed on a SpeedFX motor – but this applies to virtually all slot car motors.

The following 17 steps cover the basics – after that is starts to get a lot more complicated and technical.

Step 1 – Strip the Motor

The brush spring retainer tab should be bent inwards slightly such that you can “pry” out the end of the brush spring with a small screwdriver. It should not be bent so far that you have to bend it open each time you need to remove a spring – if you bend this tab more than a couple of times it will break off – so now is the time to set it correctly. Bend it inwards or outwards as required.

You also don’t want the spring to come out too easily or it may simply “jump” out in a crash.

Release the springs – being careful not to let them fly off (you may never see them again).

Check that both springs are set the same – in the photo above they are different (as supplied). If the springs press unequally then a side load is imposed on the bearing which will waste power.

Normal setting is 90° (as per the left spring above), bend until both are the same.

Never use a mismatched pair of springs.

Some people prefer a “softer” setting - i.e. less than 90° - this reduces commutator friction and contact (current-carrying) pressure so it's obviously a trade-off. As the brushes wear down this angle is going to get less and less anyway.

I prefer to run the motor in at 90° and then reduce it slightly – to about the position of the right hand spring in the above photo.

Remove springs and brushes. Note: the springs are left and right handed.

Note: It is possible to remove the spring “backwards” – remove brush end, lift coils off the boss, and remove the long end from lug. This works for overset lugs.

Next: Remove the “seal” decal.

Mark the “top” side - in this case it is self evident because of the axle cut-out in the rear of the can and the magnet retaining tabs at the bottom. It is not always so.

You don’t want to get the can reassembled the wrong way around as the motor will run in reverse (yeah, sure you can just reverse the wires – but it’s a bit of a giveaway in “sealed motor” rules if your wires are on backwards).

Remove securing screws.

If the crimp-in tags are bent in, pry them up with a small screwdriver. If you have “sealed motor” rules you need to bend these back on reassembly. If not, don’t bother. I normally panel beat these flush with the can after disassembly if I’m never going to use them again.

Remove endbell and pull apart.

Note: The blue magnet and the endbell bush simply came out with the armature as I pulled it apart – this is the kind of bad fit up we are trying to eliminate.

Note: The white magnet is on the left (axle side) – again if you get these the wrong way around the motor will run in reverse with normal connections – so watch it.

Step 2 – Fix the Bearings in Place

Push the bronze bush out of the plastic end bell Wash the bush, endbell, and motor housing in a solvent such as naphtha. An old 35mm film canister makes a great slot car motor washing machine.

- NorCalJim likes this

#3

Posted 12 July 2014 - 04:07 PM

Use a butane torch to solder in the front bearing – solder around the outside edge. Be careful not to get solder into the bore of the bush – if you do the bush is useless and it will have to be replaced.

Tip: get solder to take on the can first and let it spread to the bush.

If your rules permit it, replace this with a ball bearing – also solder in place. Bearing is a metric flange MF52ZZ (KOYO, JAP or similar). For a ball bearing, tin OD and can hole with a soldering iron and flux, fuse into place with a low flame or large soldering iron – don’t “blue” the ball bearing.

Place a drop of cyanoacrylate "superglue" in the endbell and push the bush solidly back into place. Same caution – don’t get superglue into the bore of the bush.

Tip: Get a drop of superglue onto a piece of scrap copper wire and use that as a probe to apply the superglue – this way you can avoid over-glueing.

You might also use a ball bearing here – but generally I don’t bother.

Step 3 – Check Bush Alignment

Check the alignment of the bushes using a 2.0mm shaft. Here I am using a 2mm die ejector pin (available from engineering suppliers like Toolquip) – you can obviously just use the armature – to check that it spins freely.

If it is tight try to find out which end is causing the problem and use the pin to flex into place – you may end up resoldering or reglueing to cure the problem – Do not use the armature as a prybar.

Step 4 – Check Brush Hood Alignment

Use a brush hood alignment bar to ensure the commutator brush hoods are accurately aligned. Here you must use a 2.0mm pin – you can’t use the armature for obvious reasons.

An alignment bar is a rectangular bar the same size as the brush with 2mm holes at right angles – this is in case you wish to set the brushes “horizontal” (with the thick side across the commutator) or “vertical” (with the thick side along the axis of the commutator). See later – info section on motors and timing.

You should also be checking the fit of your brush hoods to the brushes – the alignment bar also permits you to squeeze or panel beat the hoods to a better fit.

Ideally the brushes should slide freely with as little clearance as possible.

Step 5 – Check Armature/Magnetic Field Alignment

Push the magnets fully home against their retaining tabs. They should be flush against the outboard ends of the can and both should be in the same position relative to each other – if not bend the offending tab until they are identical.

Loosely assemble the can, armature, and endbell (no need to replace the screws).

Spin the armature with your fingers and allow it to freewheel to rest.

Push the shaft in to see if there is clearance between the armature and the endbell bush. The push from the endbell end to see if there is clearance between the armature and the can bush.

What we want is for the armature to spin and self-center itself inside the magnetic field and come to a halt with 0.1-0.25mm clearance (float) at both ends.

We do not want it rubbing at either end.

Remember, under power the armature will pull hard towards the magnetic centerline and if it is prevented from doing so will bear hard against the offending bearing bush. This will result in a loss of power to friction.

If it is bearing hard against the outboard (can) bush as is the case in the photo above we need to push this armature spacer further back. But before doing so we need to check the position of the commutator relative to the brush hoods.

In the above photo there is excessive clearance at the endbell - I have already adjusted the outboard spacer as far back as it will go – I cannot go any further or the brushes will run off the edge of the commutator.

If you reach this point it has become necessary to move the magnets backwards towards the end bell until there ist some clearance between the armature and the outboard end.

Photo above – adjusting spacer using a pinion pushing tool.

Do this incrementally, checking at each adjustment for clearance or until you run into the limit imposed by the edge of the commutator.

If you need to move the magnets back towards the endbell, do so by bending the magnet retaining tab using a punch and hammer as per photo below.

Make sure you do both the same and do so incrementally checking after each adjustment.

Bending magnet restraining tabs backwards (if necessary) to move magnets back.

After getting clearance at the outboard end we need to set the clearance at the endbell. In this case it needs to move out (which is a lot harder than inwards).

You can shift it using a sharp pair of diagonal cutters as a wedge. Alternatively add motor spacers, which is safer.

Note: This motor uses push-on spacer/thrust washer combinations. Some motors simply use loose spacers. When using spacers there should always be a phenolic (plastic) spacer immediately behind the commutator.

You must obviously adjust the “tight” end first; in this case it was the can end but could just as easily been the endbell.

A selection of motor spacers.

#4

Posted 12 July 2014 - 04:19 PM

Step 5 – Superglue your Magnets in Place

Once you are satisfied that you have free running clearance at both ends of your armature (0.1 to 0.25mm per end and about 0.3-0.5mm total “float”) then it is time to permanently glue your magnets in place with superglue. After going to all this trouble to get everything aligned we don’t want the magnets moving in a crash.

CAUTION: Before doing this use latex gloves or apply barrier cream to your hands – especially if you have been using naphtha – cleaned skin can become permanently attached with superglue. Please be careful! You can become way too attached to your hobbies.

Dribble superglue into all the edges around the magnets.

Glue any place you can get to. Allow to cure.

If at this point you are having any bright ideas about using glue to space the magnets closer to the armature for more power performance – you would be hopelessly wrong – see detailed explanation later as well as tips for shimming, etc.

Now would be a good time to zap your magnets (see later.)

Step 6 – Set up your Armature

This is your armature.

We are going to do the following – in this order:

1) Set the spacing (as per above).

2) Check/set the “timing”.

3) Solder the commutator.

4) Add binding (if absent).

5) Replace shaft (if badly bent and worth the effort).

6) Balance the armature.

7) Skim the commutator.

STEP 7 – Check/Set Timing

See later for a more detailed explanation of why a slot car motor needs advanced timing but for a 16D you need about 25-30° advance; a Group 12 needs about 45° advance.

Zero degrees is when the gaps in the commutator align with the center of the armature poles.

Advanced is when the gaps are offset counterclockwise (the direction the motor runs in viewed from the commutator end).

Note: This is only true where the brushes lie in the same plane as the magnets – it is not true for motors such as NC5 and 6, which have their brushes at an angle to the magnets and also have an offset wind.

You will need a gauge – so here is one…

Stick it onto a piece of card and make the hole in the middle to suit the armature – or you can go mad and stick it to a piece of aluminium 60mm dia. x 13.5mm dia. x 10mm thick with an M5 securing screw hole at 0°.

Set zero at pole dead center (sometimes there is a marker groove, as in this case) or align markers to gaps symmetrically. Use a straight edge to take a reading from a commutator groove to a parallel line-up on the gauge – when viewing from directly astern. (This photo is off center so you can’t correctly see that it lines up at 29°)

Caution: measuring is one thing – adjusting is another.

Adjusting can result in the destruction of the commutator or broken wires, etc – throw the armature away – don’t attempt to adjust unless it is really necessary or you are confident you can do it (and that you want to do it).

Adjustment: first check there is sufficient slack in the wires to the commutator to permit the adjustment. If your armature is “bound” – securing these wires – you will have to remove the binding and replace after adjustment.

Next: Attempt to twist the commutator using your fingers – this is the safest method. If you can’t shift it, consider giving up or move on to more brutal methods.

Use a chuck to grab the comm by the connector diameter (slightly bigger than the comm itself) while simultaneously turning up against the connector points themselves.

In the above photos the binding is still in place (illustrative only).

Move in small increments, check frequently for tight wires which may be as far as you can go.

With soldered comutators it is sometimes advisable to desolder the wires, make the desired adjustment, and then resolder them.

Step 8 – Solder the Commutator

Due to idiotic lead reduction laws (Caution: this product may contain substances harmful to pregnant women – I know pregnant women get cravings but I never heard of one eating a slot car armature?), many armatures have their leads clinched to the commutator – these invariably become bad connections.

I grew up in a house with lead plumbing and it hasn’t affected me in the slightest – just ask any of the talking plants that follow me around all day.

Caution: Do not solder the commutator unless you have access to commutator truing facilities such as a lathe or a Hudy comm truing machine or similar. (You are going to need it if you solder.)

To solder a commutator, you need high temperature solder.

Two problems: it can be hard to get hold of and it doesn’t solder well.

Here’s a tip – drill a block of lead and keep the lead swarf strands produced.

Solder with your favorite solder and flux – then add the lead strand until the solder won’t accept any more – you have now raised the melting point (by adding lead) to pretty much as high as your iron will go.

Making lead swarf to add to solder.

Add lead to solder. Alternatively add high temperature solder after tinning with your most user friendly solder/flux first.

Solder will almost always reach the comm – hence the need to skim. Whatever you do, don’t get solder to bridge the slots – it’s a bugger to scratch out.

#5

Posted 12 July 2014 - 05:24 PM

Step 9 – Adding Binding

The binding or wrapping of the wires below the commutator stops them from flexing with every up down spin cycle which eventually flexes them to breaking point.

If your armature is not wrapped – bind it with Terylene or Rayon cord (the stuff they use for “whipping” fishing rods, available from any tackle shop).

Bind (4-5 turns depending on thickness), knot, lacquer (clear nail polish will do) allow to dry then trim.

Note: Lacquering also helps re-secure the comm if you have moved it. If you found the comm easy to move you can add a dab of superglue to the back of the comm before binding and lacquering.

If you are fussy, use General Electric “Glyptal” clear armature lacquer, which is specifically made for the application – if you can get hold of it (it comes in 5 liter cans).

Inspect the windings for any loose turns (these will fret and ultimately break) and if found, lacquer to secure into place.

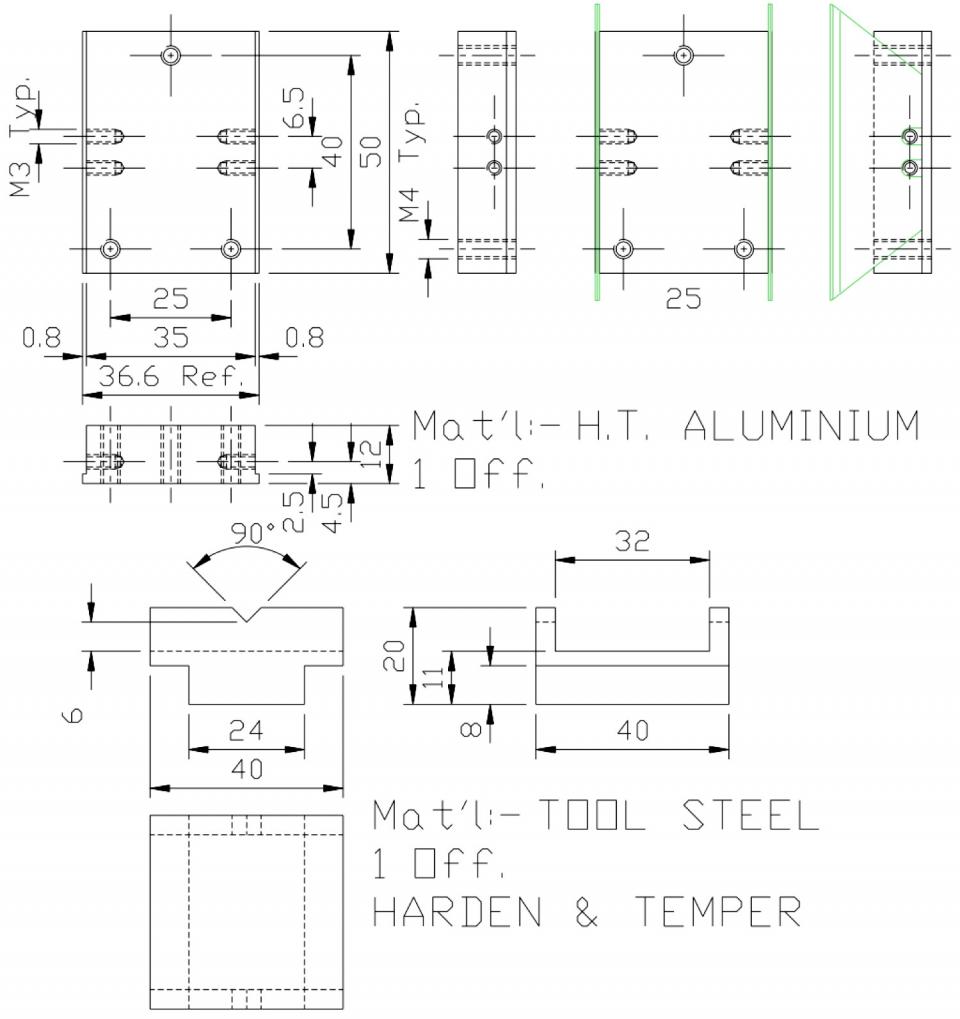

Step 10 – Replace the Motor Shaft

A shaft might become bent in a crash. It can be replaced by pushing out the old shaft with a new one (use a 2.0mm ejector pin from an engineering supplies shop – cut to the right length).

This is not as easy as it sounds – you need special tooling to keep everything lined up and to prevent the shafts from buckling.

You start with both (short and long) anti-buckling spacers in – when it dead-lengths remove the short one, when it dead-lengths again swap the long one with the short one and finally after it dead-lengths again remove the short one and complete the assembly. This will prevent your replacement shaft from buckling under the load of insertion (particularly if it’s a tight fit).

Note: Detail 3A supports the lower end (spacer tube/whatever) of the armature and should just bear against it when the armature is loaded against Detail 6 – armature support.

The keyway Detail 4 is very important to prevent rotation (Detail 1A – Key runs in this groove) – without it you will twist off the commutator (you can guess how I figured that one out).

Details 5 and 6 have alternate diameter ends to shroud/support different diameter armatures.

The above PS700B arm was damaged by failing to lubricate the rear bush – after shaft replacement and a comm skim it was as good as new.

Step 11 – Balancing the Armature

Static vs Dynamic Balance

If you simply add or remove weight from an out of balance object until it shows no tendency to rotate, this is termed “static balance”. It is obvious that you have probably not added or removed the weight from exactly opposite the error so when the motor is rotated at high speed it would still be out of balance to some extent.

“Dynamic balance” is accomplished by rotating the object at speed and analysing (on a sophisticated machine) the amount and location of the errors so they can be corrected for the object in motion.

It follows that a dynamically balanced object is also statically balanced (but not vice versa).

These motors are dynamically balanced but since this is a mass production process the balancing process is generally imperfect.

Dynamic balancing is way beyond anything you can do at home. (Having said that the web holds many plans for home built rigs so it is possible.)

So we go for a static balance on the understanding that if it is not statically balanced then neither is it correctly dynamically balanced and any improvement we make statically must still be better than leaving it as it was.

Balance on Stanley Knife blades is done like this:

You can make the block from dense fiberboard (see drawings). The three levelling screws are used to eliminate any slope or bias.

Use brand new blades and be careful not to drop the armature onto them – place it very carefully in place – otherwise you create dents in the sharp edges which become obvious as biased behaviour).

Get it levelled so the armature does not roll to one end or the other by itself.

Allow the armature to roll (push it) slightly – if it has a heavy side it will always stop in the same position. Rotate multiple times to be sure.

If you can positively identify a heavy side – remove from the blades and drill material out of the heavy side.

Note: if it stops with one pole facing up and two down you must drill both “heavies”.

Use a 3mm drill – if there are two holes in that pole remove material equally from both. Don’t go too deep (max 0.5mm parallel portion depth). If you need to remove more, drill a third hole in between the existing two. If you drill too deep the core may break out at high revs.

Remove material in very small quantities, checking frequently. Repeat until the armature comes to rest in any position.

You can further “fine tune” balance by adding weight – just add a dab of lacquer to the “light” side windings – and repeat until balanced.

Caution: Keep in a safe place or container when not in use. These sharp blades are a real hazard if simply left lying around.

Step 12 – Balance the Armature (with a hammer???)

If you are simply checking an old armature that you know for a fact was balanced but is now out of balance – particularly if it is severely out of balance, then the armature shaft is bent.

Note: Small changes in balance are normal due to heat softening of the winding lacquer and some shifting of the winding during hot use. If in doubt check the run out with a dial gauge. Don’t use this method unless you are sure the shaft is bent.

Since it was in balance then we can correct it by bending it back – by hitting with a small hammer on a suitable anvil until we get it back into balance, at which point the shaft should be straight again.

Hit on the anvil (heavy side up) – never on the blades.

If you get somewhere close to balance – stop hitting (it is unlikely you will ever get it completely right with something as brutal as a hammer) and go to drilling it back to balance.

Step 13 – Skim the Commutator

When the commutator was made it was probably diamond turned by some inscrutable oriental gentleman in a factory in Wanking.

Unfortunately after all the slings and arrows of assembly and errors in the shaft and assembly process, etc., it is almost certainly no longer exactly true by the time it leaves the motor manufacturer (high cost/quality armatures are turned after assembly).

We have by now also got solder onto the running surface so all in all we need to give it a skim to restore it to true.

To do this you can use a Hudy commutator truing machine or, my personal favorite, a bench lathe.

You need a very sharp cutting tool in high speed steel or Syndite (synthetic diamond) with a large side rake and ground almost to a polish on very fine wheels. Keep this tool only for skimming commutators.

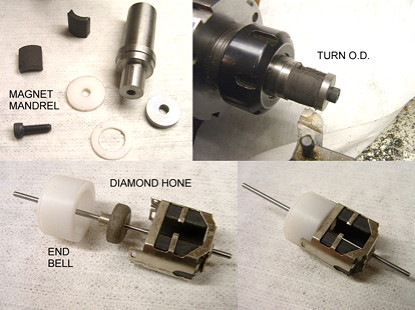

You also need a clamping bush and a tailstock bush – refer to photo below.

Mount clamp bush and secured armature in four-jaw chuck and adjust to true with a dial gauge.

Run the commutator end in a guide tube (a piece of 5mm brass rod reamed to 2.0mm) in the tailstock drill chuck. (You could also use a motor bush in the drill chuck – but tool access can be a problem.)

Apply paraffin or turpentine as lubricant with a brush and turn at 2,000 RPM, taking very light cuts until the commutator cleans up.

When skimming an old comm, you get to see how bad it was as it cleans up.

If you do it right with a suitably sharpened tool then the grooves will not need deburring. If they need deburring use a sharp Exacto knife and a sharpened toothpick to clean out the grooves.

Give it a final polish using #1200 water paper with paraffin or turpentine as a lubricant. Do not use any form of chemical polish on the commutator – it may look good but the chemical residue doesn’t come off and the comm blackens and burns to a crisp in no time. You have been warned!

Finally clean the armature in naphtha and you’re good to go.

Skimming the comm generally does not upset the balance (unless you removed a stupidly large piece of solder in the process) – so you might just want to return it to the balancing rig for a final test.

Our completed spaced, bound, soldered, balanced, and trued armature. To save yourself all this trouble you can buy “blueprinted” armatures – you still have to set the spacing.

Below is a Pro Slot “blueprinted” armature – almost perfect – there is nothing you can do to improve this arm.

The above Pro Slot PS700B ("Big Dog") armature – CNC wound, thin laminations – is perfection and a work of art.

Note: Most rules permit “standard” 16D which is 60 turns of 28 AWG wire. Most rules also allow the Pro Slot PS700B (“Big Dog”) armature which is 55 turns of 30 AWG wire and runs highly timed at 36° - this armature generally requires you do something to up your magnetic field circuit strength – see later – that might not be permitted.

#6

Posted 12 July 2014 - 05:45 PM

Step 14 – Cut for Axle Clearance at the rear of the Motor

At the beginning I might have cautioned about cleanliness and particularly avoiding getting iron filings attached to the motor – all good and well, please do so.

But this next step is going to make a mess – no way around it – so we will still have to clean up before assembly.

The rear of the motor will in most cases foul the rear axle (in spite of the cut-out in the can) so we normally grind a groove here. This is best done with the motor disassembled – it is difficult to get all the junk out of a closed motor.

Grind out using a diamond-coated burr and a Dremel. You can also do it on the corner of a grinding wheel but that is not as good.

Compressed air will normally drive out all the dirt – if don’t have an air source, use a sticky putty to mop up all the dust that has stuck to the magnets.

I can’t say I have ever noticed any loss of performance from grinding the magnets in this way.

Step 15 – Grind in the Motor Brushes

Motor brushes are only partially shaped (in some cases they are simply flat faced) – we don’t want to run the damn things for hours to get them bedded in so we grind them – here’s how to get them to conform to the comm.

First make a brush “file” – you can buy such things but they are easily made. As in the photo turn a mandrel with a 2mm diameter pilot shaft and a diameter that matches your commutator – less the thickness of the #600 emery paper you are going to glue on with contact adhesive. Finished diameter should be the same as your commutator.

Cut the piece of water paper and trim until it fits perfectly – apply glue and bind with elastic – allow to cure.

Fit into endbell, assemble brushes and springs, and rotate by hand to grind brushes – check frequently.

You don’t have to take your motor apart for this when replacing brushes – keep an old (but properly aligned) endbell handy for just this purpose.

Be sure to put the brushes back in the same way for further grinding or assembly. It might help to scratch a small identifying mark on each brush for this purpose – I normally mark them with - and + with the mark towards the terminal lug.

Step 16 - Reassemble the Motor

When replacing the securing screws, try to reengage the original thread – sure, they will self-tap a new thread but will far more easily strip – particularly if you do this several times.

Apply a drop of oil to each bush – do not over-oil. I use automatic transmission fluid (ATF).

Step 17 – Run in the Motor

If you did not trim the commutator then it might be an idea not to grind the brushes and run the motor for an hour at 3-5 volts, an hour at 6-10 volts, and finally goose it up and down to flat out for several minutes.

If you skimmed the commutator and ground the brushes – run the motor for 5 minutes at 5-6 volts and finally goose it up and down to flat out for several minutes.

That’s it.

Step 18 – Admire your Handiwork

It sure as hell doesn’t look any different after all that effort, but believe me it will go like the clappers.

#7

Posted 12 July 2014 - 06:37 PM

Omissions & Advanced Topics

There are a couple of items I have not covered under blueprinting as these are generally “out of bounds” for 16D class racing - but will discuss these now.

1) Checking the can bush is dead center – some people make a big issue of this. Personally I have not found this to be a problem. Sure you obviously would want your armature running dead center symmetrical to the magnets but If you read on you will see why it is not that big a deal (the position of the armature inside the field will not have much effect on the overall magnetic “circuit” strength).

2) Shimming the magnets to increase the strength of the magnetic circuit. The use of “focussed” quad pole (or more) magnets.

3) Shunted motor brushes.

Obviously 1 and 2 go hand in glove but if we are talking 16D class racing, this goes outside the category of “blueprinting” and maybe into the realm of “cheating” - depending on your club’s rules.

Check your local/national class rules before modifying a motor. There is no point in winning by cheating – or finding yourself disqualified after winning – scrutineering tends to get more intense the more you win.

Now familiarize yourself with what follows for a more comprehensive understanding of what makes a slot car motor tick. This understanding will help you make better decisions.

SLOT CAR MOTORS

Brush gear & timing - all you ever wanted to know (and probably a lot that you didn't)

Why does a slot car motor need to have an advanced commutator and just how much should it be advanced?

A complete technical discussion of the problem is too horrible to contemplate, involving complex subjects like hysterysis, reluctance, back EMF, phase diagrams etc. etc. You don’t want or need to know so we will keep it simple…

When an electromagnet (the armature pole) is switched on it does not instantly reach its full magnetic power. This delay is very small (milliseconds) but in a motor turning at 1,000 revolutions per second it is a serious problem.

To improve the performance of the motor the commutator is "advanced" - turned further in the direction the motor is turning - so that the power is switched on earlier in order that maximum (or at least optimum) magnetic strength is achieved when it is most needed.

The timing can also be advanced by rotating the brush holders in the opposite direction to rotation. This achieves exactly the same result as advancing the commutator. (The new Slotworks and Pro Slot motors have adjustable endbells)

A slow turning motor would not need to be advanced and could be run clockwise or anticlockwise with the same results.

A high speed motor is advanced to give optimum performance in one direction and at one speed only.

Running an advanced motor backwards (i.e. running it retarded) for any length of time is a good way of converting it to smoke.

The degree of advance chosen by the manufacturers is also optimum for a given set of circumstances (field magnet strength, stack length, wire turns, desired rpm, etc., etc.)

Under braking, the motor is acting as a generator and the situation is reversed; here we would need to retard the timing to improve the performance of the "generator" at a specific speed.

So advancing the timing degrades the motor’s performance as a generator – hence less “brakes”.

So we have to settle for an advance setting which is a compromise between top end and braking. This is just one of many compromises that have to be considered in the design of a slot car motor.

More advance will give you more revs and improve the higher end torque but will cause reduced braking.

More advance will improve power at the higher revs but at the cost of a disproportionate increase in current and heat and a loss of low end power and torque.

You can over-advance a motor, i.e. you have advanced the commutator to a position for optimum 8,0000 RPM which is simply unobtainable (given the motor's power) on the racetrack.This will result in overall poor performance, very poor braking, massive current, and eventually - smoke.

This motor might "sing" on a bench but be lousy on the track.

Just for reference, a Parma 16D driving 17.5mm diameter wheels at a lap average of 22 KMH through 10/38 gears is rotating on average at 25,343 RPM, probably reaching peak loaded RPM of 45,000- 50,000 rpm. Unloaded it spins at about 60,000 RPM at 12v.

At 60,000 rpm the armature poles have to change polarity 2,000 times a second - fast!

If we assume that the manufacturer has chosen the advance setting correctly (and built the motor properly) then we would probably be unwise to adjust the timing.

However this assumption is probably faulty - the Parma 16D is nominally factory produced at 20° advanced; in practice this can vary by several degrees.

Also the Parma brush hoods are lousy and poor brush line-up also affects timing, as do many other factors such as magnets, driver preference, etc.

Motor Brushes

In a three-pole slot car motor the ideal brush would have zero resistance and be paper thin. Even if such a magic material were available it would simply fall into the gaps in the commutator and jam the motor.

The insulating grooves in the commutator have to be wide enough to prevent arc tracking across them and the brush obviously has to be wider than this in order not to fall in.

Unfortunately this mandatory requirement that the brush be wider than the grooves leads to short circuiting of the voltage across the gap (this is very much lower than the applied voltage).

If the brush were a very good conductor this would nonetheless result in high short circuit currents.

Consequently all brushes are made slightly resistive, this being a compromise between the requirement for good conductivity down the brush and poor conductivity across the face of the brush. Brush technology is a science all on its own.

So we make the brush face wider and wider; this leads to improved connectivity.

Some people think a wider brush leads to a longer power on period, but in reality it doesn't. (It does change the shape of the applied voltage wave during the weak periods in the field but that's way outside the scope of this article and it's a non-event with three-pole motors as other nasty things happen first)

As we make the brush face wider we will see an improvement in motor performance but we eventually reach a stage where the under-brush shorts negate any improvement created by the increase in width.

In three-pole motors we unfortunately reach the point where one segment of the commutator can touch both brushes leading to a true short circuit (to the applied voltage).

This is a really serious problem as under a true dead short condition, not only can no power get into the motor but the existing magnetic fields collapse rapidly adding to the short circuit current and effectively applying "brakes" during the period of the short.

Note: because of the resistive nature of the brush it is never a true short circuit. Also the under-brush pressure diminishes (to the Cosine of the angle) towards the edges, the pressure there being typically 75% of the centerline pressure.

All sorts of claims are made for brushes like “Golddust”, “Big Foot”, etc., and they are very good – the more copper in a brush, the better its conductivity – the more carbon less conductive.

It follows that the “blacker” a brush looks – the more carbon (and generally cheaper) it is.

However you could have an armature that runs badly on a quality brush like a “Big Foot” and better on a “cheap” brush, the higher carbon brush being less trouble with under-brush and brush to brush shorts.

However I would generally go for the higher copper content brush. There are some very expensive silver/copper formulations – which under the right circumstances might be better (re: cautions above) but probably not in in a standard 16D setup.

See next section for technical explanation of brush alignment problems.

Above silver/cCopper brushes with built-in “shunt” wires – see later section on “shunts”.

Brush Alignment Issues - Technical

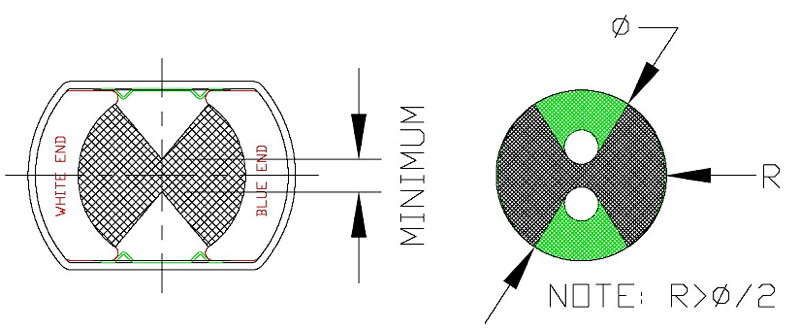

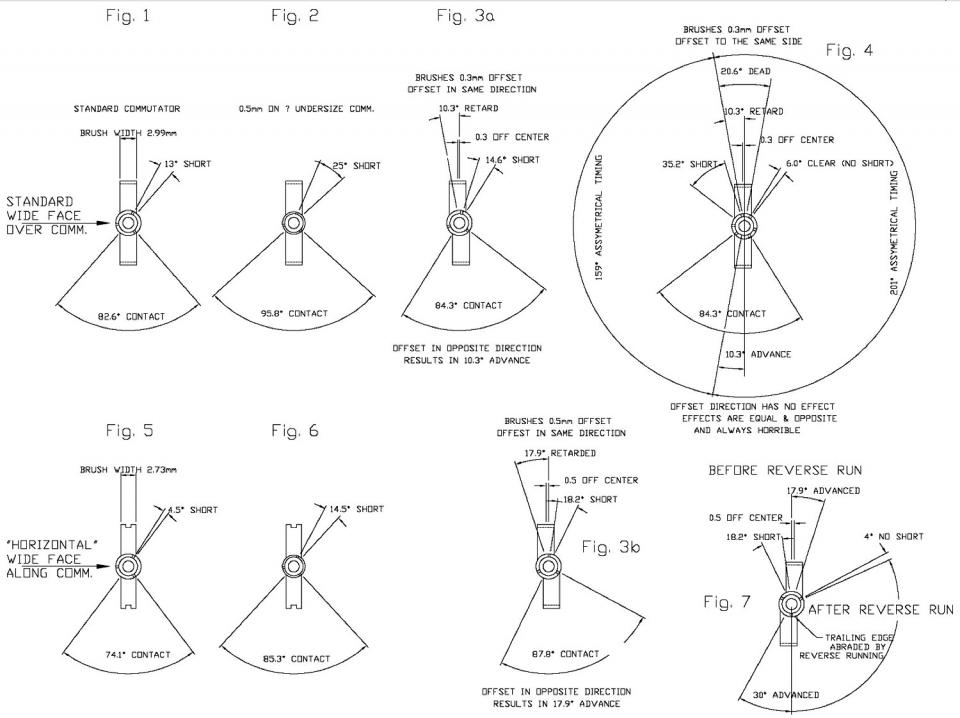

Refer to the drawing below.

Fig 1 - Shows a standard Parma 16D commutator and brush arrangement using the broad side of the brush as the width (refered to in some publications as a "vertical" brush, i.e. with the slot in the back of the brush vertical).

This gives 82.8° of contact and 13° of short - remember this 13° occurs six times per revolution or 21.6% of the time the motor is running it is shorted - Aaarrrggghh!!!

Fig. 2 - shows a "horizontal" brush arrangement (narrow side of the brush as the width) which gives 74.1° of contact and only 4.5° of short or 7.5% of the time the motor is shorted.

Arguments over which arrangement is better wax and wane in US publications - my money is on “vertical” but use "horizontal" on an undersized (from truing) comm.

However this is not the real problem - the Parma brush hoods are lousy and brush alignment terrible as a result. Tiny errors in brush alignment leads to huge errors in both timing and short durations. See diagrams and explanations further on.

Also if the diameter of the commutator is reduced by skimming, massive changes occur - see Fig 2 - the commutator has been skimmed 0.25mm (0.5mm on diameter) contact has gone up from 82.6° to 95.8° and the short from 13° to 25°.

Now I don't know about you but I don't want my motor shorted out for 42% of each revolution.

I would suggest that if you have to significantly skim the commutator you switch to "horizontal" brushes. See Fig 6.

One of the more common problems with the Parma hoods is that the brushes offset to one side. Because of clearance in the brush hoods they shift in the direction of rotation which also retards timing. At only 0.3mm offset the timing is retarded 10.3° and shorting increased. At 0.5mm offset our timing is retarded 17.9° and shorting is 18.2° or 30%

Obviously if offset the other way it advances the timing - this being a fairly common "cheat" to advance the timing where this is not permitted.

Since any clearance in the brush hoods (and there must be some) will allow the motor to tilt the brush slightly which will always retard the timing and increase the short duration.

This is why running your motor backwards for a short while before a race helps (sometimes). The trailing edge tilts into the commutator and is rapidly abraded away so when you run your motor the correct way your timing is advanced and your short duration reduced - at least until the brushes fully settle in again – see Fig 7.

So far so bad, but it gets worse.

All the above assume symmetry - if the offsets are in the same direction - see Fig 4 - then it really goes to hell in a handbasket.

In Fig. 4 we have only a 0.3mm error but it results in asymmetrical application of power so that through 20.6° the motor is pulling and pushing simultaneously - simply defeating itself! Remember this happens three times a revolution.

Plus we have a 6° no-short on one side (which does not help us) and a 35.2° short on the other (which also occurs three times a revolution. So this motor is shorted for 29.3% of the time and "in neutral" (but generating heat) for 17.2% of the time.

Combine this with an undersize commutator and it gets worse, a near certain recipe for hot copper to run out of your armature.

The obvious conclusion from this is that brush hoods must be very accurately aligned. This is probably the most important setting on your car motor so get it right.

If your brushes are skewed they should at least be symmetrical.

If you find that your motor performance improves after fitting new brushes but starts to deteriorate after some bedding in then look at the contact angle on the face of the brush when you feel that your motor is running optimally (make a sketch) then file away the leading and trailing edges of the brush to this sketch whenever you feel performance is going off.

Consider switching from “vertical” to “horizontal” if this is the case.

This switch is not as easy as it sounds as you need to modify or panel beat your brush hoods to accept and accurately guide this new configuration.

In some motors the fit is so bad (loose) that you can turn the brush – that is not good news – it's ridiculous – fix it – brushes need to be accurately aligned.

The Pro Slot detailed in the blueprinting section has excellent hoods and alignment. You would not be able to switch from “horizontal” to “vertical” on this motor without modifying the hoods.

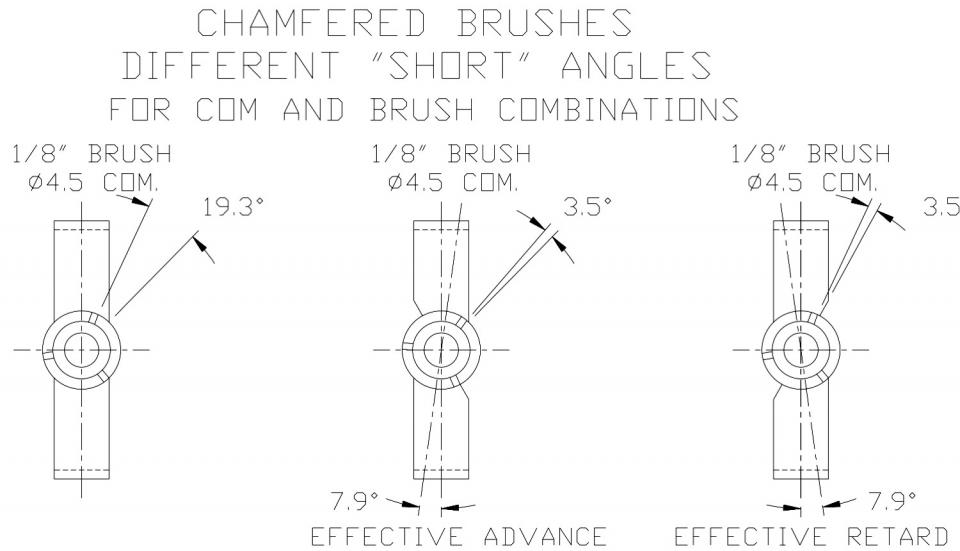

For yet another trick you can remove material from the trailing edge of the brush – chamfer say 0.5mm at 30° this will reduce the effective brush width, reduce potential underbrush shorting and advance the timing. Similarly you can try the same thing on the leading edge this will do the same thing but retard the timing.

The diagram above shows how chamfering a brush by 0.5mm at 30° can drastically reduce the short circuit angle while simultaneously advancing or retarding the timing depending on which side you place the chamfer. (Removing 0.25mm from both sides would reduce the shorting angle but leave the timing unchanged.)

It follows that a great deal of “fine tuning” can be accomplished by fiddling with your brushes.

If you find a “setting” that works well you will need to periodically remove the brushes as they wear to re-establish the correct chamfer.

The obvious drawback is that will require frequent attention as the brushes wear and is therefore only suitable for sprint racing.

The next diagram shows the effects of imperfect alignment.

Some motors have absurdly small diameter comms (relative to brush size). The Parma uses slightly smaller cross section brushes (3mm as opposed to the more common 1/8” {3.17mm}) because of its small commutator.

I prefer a larger diameter commutator for less underbrush shorting - but this also increases power losses to brush friction – everything on a slot car motor is a trade-off.

See diagram below for the difference in short circuit angles for various combinations.

Advanced Points

Repeat note: Check your local/national class rules before modifying a motor. There is no point in winning by cheating – or finding yourself disqualified after winning – scrutineering tends to get more intense the more you win.

Brush Shunts

Slot car motors can draw a lot of amps - on in-rush particularly – up to 10A on a 16D and 20A on a Group 12 often limited by the track surge amps to anywhere from 15-25A depending on local regulations.

That current can only get to the armature via the brush spring or via the friction connection of the brush in its hood. Needless to say thebrush spring is not a good conductor and neither is the brush itself or the friction nature of its connection to its hood.

Having said that the wall of the hood is going to conduct through less brush as its closer to the commutator – but when it loses contact (as it will do frequently) then the current is passed via the spring and down the brush (the worst route possible). Also the spring can heat up making things worse even going so far as to soften and fail completely.

Some motors use a plastic spring post which will get burned off by an overheated spring – such posts should be protected by a metal sleeve. Most quality motor manufacturers now use metal bobbins instead.

Pro Slot motor with aluminum bobbins for springs.

Plastic post with heat sink sleeve.and shunt wires.

The advantage of using a brush with an attached pigtail lead (or shunt) is that power is supplied directly to the brush and into the brush for ±3mm (minimum length) so it's better all round. See earlier photo.

We cannot add a pigtail to plain brushes (I have done it but you need tooling and breakages are common – it’s difficult). However we can add a shunt wire from the terminal tab to the brush (as in the above photo of a Mura motor) – it’s obviously soldered at the tab and at the brush it is simply trapped under the brush spring in line with the spring.

This is how you go about doing it. You can buy the lead but it’s just as easy to strip a piece of old multistrand flex leadwire.

You are going to need a pair of shunt leads ±13mm long – so start with a length about 35mm and solder it (quickly to prevent “wicking”) in the middle – yes, the middle! Then as lightly as possible at either end.

Now we only need 1½-2½ mm of soldered length to solder to the tab so cut through your soldered section of wire about that far from where the wicking stopped – i.e. check where the wire can flex normally and cut accordingly.

At the brush spring end we cut just short of where the wicking ends – we only want the barest minimum of solder here to prevent the shunt from unravelling itself.

Next add a spot of oil just below the soldered end and allow it to wick in – this will help prevent further solder wicking in to it when we solder it to the tab.

Next solder tin the tab – do this before attempting to solder the shunt in place.

Next hold the shunt wire just below the solder with needle nose pliers or tweezers – this is also to stop further wicking – and then quickly solder it to the end of the tab closest to the motor – this to leave the remainder of the tab available for the leadwire without unsoldering the shunt lead and risk further wicking.

Next route the free end to the brush and secure with the brush spring. Ensure there is free play in the shunt and that it is not going to foul anything – particularly as the brushes wear.

Also remember that crosswire will foul the brush hood before the spring does – so keep an eye on brush wear.

Some references will tell you to insulate the brush spring at both ends with winding lacquer – frankly I don’t see the point (it’s to stop current flowing through the spring – I get that much but it’s so much lower with a shunt that it’s not worth worrying about) – if the shunt fails, the worst that is going to happen is you are back to the usual spring connection whereas if you insulate your spring and the pigtail fails you might come to a halt (the friction connection will keep you going but tends to be intermittent and worsens when it is the only source of power.)

It’s your choice.

- Rob Voska likes this

#8

Posted 13 July 2014 - 06:43 AM

Is it an improvement?

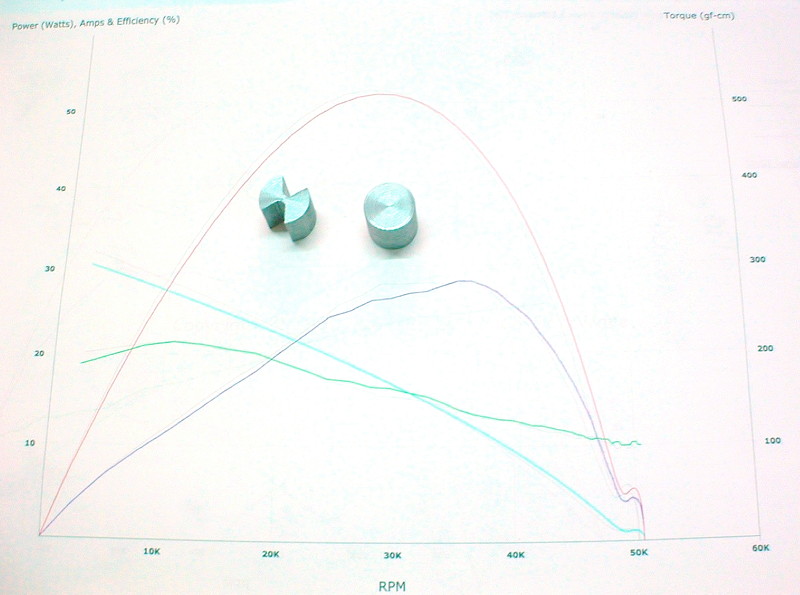

This is the same motor I have been using throughout this article and you will see further power curves on it later (but fitted with a “blue” Pro Slot blueprinted arm.)

Below – back to back trials with and without the shunts.

(click on graph for a larger view)

The lowest (51.77W) curve was without the shunts.

The highest (colour – 56.47W) was with the shunts.

The middle (55.08W) was for the shunts in place but unsoldered from the tabs. What this shows was there was a gain in power of 3.31W (55.08-51.77) due to the increased spring pressure being applied because of the shunt under the spring, rather than by the shunt itself.

The true gain from the shunt itself was 1.39W (56.47-55.08) or ±2½% gain – certainly worthwhile but not a huge advantage – but like they say every little bit helps.

Brush Hoods

These bits are what typically make up your brush hoods.

There are other arrangements using much more rigid machined tubes – typically made from extruded brass (hexagon outer, square/rectangular hole) which are typically soldered to the backing plate to improve heat sink capability.

Above is a Mura motor with solid tube hood sleeves, shunt leads, and enlarged heat sink plates.

Heavy duty brush tubes.

Magnet Position

Will moving my magnets closer to the armature improve my power and performance? For a standard motor the short answer is no.

You need to understand what is going on - the resistance of the winding is very low, about 0.4 ohm, which if connected to 12 volts should pull 12/0.4 = 30 amps - we know it doesn't but why?

What happens is as the pole passes through the magnetic field this induces a reverse voltage which opposes the incoming voltage so that at (say) 60,000 RPM the induced voltage is 13.8 volts and the applied voltage is 14.2 so the current drawn is (14.2-13.8)/0.4 = 1.0 amp.

(This is a simplified explanation – the truth is a little more complicated relating to the impeadance of the electromagnet – it is in fact an AC device – notwithstanding that this is a DC motor - the individual poles are being constantly switched back and forth at relatively high frequencies. The expanding magnetic bubble also resists the incoming voltage.)

So if you move your magnets in you will increase the field strength and the reaction voltage will happen sooner - at lower revs. The same thing will happen if you fit “stronger” magnets.

So field strengthening reduces RPM and, as perverse as it seems, field weakening increases RPM.

But that is not the end of the story. If we move the magnets in/increase field strength - we get more torque - which is good - but in order to offset the reduction in RPM we must reduce the number of turns we have wound on our armature.

There is an optimum magnet position/strength for a given armature so armatures wound for 16Ds expect the normal field strength. Any change in magnet strength or position must go hand in glove with an appropriate "wind".

If we were to increase torque at the expense of revs then we get no overall gain in power.

It should be obvious that you might gain from shimming but more likely you won’t – it’s an awful lot of effort for “might”.

That said – with an appropriate wind – it will certainly give improved performance.

OK, you didn't listen and want to mess with your magnets anyway...

Shimming your Magnets

First understand that the magnets, the can, the clearance, and the armature form a magnetic “circuit”.

Since we must assume the motor manufacturer has made the core and can from high magnetic permeability 4% SiFe then the obvious point of most “resistance” to the magnetic circuit is the air gap (as air doesn’t magnetise well). Magnetic resistance is termed “reluctance” to avoid confusion with electrical resistance.

Reducing this air gap will increase the effective field strength by eliminating some of the reluctance of the air gap.

Note: Shimming your magnets with epoxy will accomplish almost nothing as the permeability of epoxy is the same as air – all you will have accomplished is to move the gap from one side of the magnet to the other. (There is a very small improvement due to the proximity of the can at the sides. It could well be that such a small increase is exactly right for your armature – so some people will swear by this modification and it is often banned under club rules – it certainly doesn’t hurt to try it, if allowed. It could well turn out that in your motor this method works better than mine – I am more concerned that you understand what you are trying to achieve.)

The same applies for brass and stainless shim stock.

Steel shim stock from an engineering supplier is OK but less than desirable.

Shimming must be accomplished with 4%SiFe – find an old transformer and use pieces of its laminations as shim stock. (Any laminations from motors. contactors etc.)

The next problem is how far are you going to shim? These motors typically have 0.6mm clearance at the center.

You will note that the curvature of original equipment magnets does not match the armature - even allowing for clearance. This is not a mistake, the pole piece is really not working all that well at the outer edges and increasing the field strength at the outer edges will amplify the under-brush shorting problems that I mentioned earlier. (See further notes on this later.)

If you shim up 0.5mm (recommended) then you can probably get away with this without having to “hone” or grind your magnets.

This will exaggerate the radial error (see picture later) and unduly focus the magnetic field towards the center. To overcome this you need to shim about 0.9mm and hone out the bore to 13.7mm diameter to leave about 0.1mm clearance (for about 90° of the magnet’s inner surface).

To further complicate matters – the inner and outer radii of the (bent) shim are the same – so its thickness varies. The 0.5mm shim tapers down to 0.38 at its edges. The 0.9mm shim tapers down to 0.64mm – you don’t have to shape the shim but if you don’t you’ll leave air gaps which is what we are trying to get rid of in the first place.

You also want to keep the honed bore shape uniform. Parallel and highly polished.

All this is very precise and time consuming work and as I pointed out earlier – if you don’t change the “wind” you will probably end up worse off (believe me I’ve been there).

I didn't mention magnet shimming/honing under blueprinting as this goes way beyond “blueprinting” and because I fear you introduce more problems than you solve.

It certainly takes your motor outside of the 16D class as a standard 16D “wind” will not perform in this set-up.

The tiny clearance can also become easily fouled.

Polishing both the armature and the magnet will result in reduced aerodynamic drag - but the reduced airflow and turbulence will result in less cooling. Having said that, a great deal of the heat is still transferred to the can and the small gap assists this, so I can't say I've ever seen this to be a major problem.

The thickness error mentioned earlier is visible in the picture above where the shim is drawn a constant thickness.

You might also need to remove burrs from the spotweld on the can or even “size” the can to get the radii to match up better (more bloody tooling).

You might also want to check that your can bush is “dead center” to the can before doing any of this. (Refer to step 3 earlier). With the motor on a shaft, dial gauge the OD of the can – if the bush is off-center you can enlarge its mounting hole – turn up a suitable plugging mandrel (to fit the can or between the magnets) to hold the bush aligned for soldering. You can also mount it in a four-jaw chuck or collet chuck on a lathe and machine an undersized soldered in bush to true dead center, etc., etc.

If you want a simpler shimming method, you can do it with epoxy filled with iron filings or my own personal preference - magnet dust. Given the problems of shim fit up this method works surprisingly well.

Make your own iron filings / magnet dust by grinding any suitable material (old laminations, speaker magnets, etc.)

Grind against a diamond wheel on a bench grinder – attach a NIB magnet to the work rest to catch all the filings.

Mix a quality slow curing epoxy and add filings until it forms a thick paste – add as much powder as you can. Use this to glue the magnets in place – use a dummy armature blank (or an old armature – depending on your required final position) – trim excess after cure.

Tip: Apply release agent to can and magnets if you want to be able to remove or trim simply after doing this – you can always superglue into place later. This simplifies rectification if you make a complete hash of it.

If you have access to a lathe you can first coat the magnets and then trim them to size (which is what I do):

I next apply the paste to the back of my magnet pair and allow it to cure, then I trim the ends and sides with a file and finally turn the OD on a mandrel specially made for the job. The Delrin/Acetal washers act as an oversize guide/non-stick surface.

Once you have shimmed your magnets and are happy that everything is nesting nicely with no gaps and you have the bore somewhat smaller than the armature, you now can glue your magnets in place and proceed to “hone” out the bore.

Shown is a home-turned endbell – hone does not always fit into the brush hood end – easy enough to knock up if you have a lathe.

You can just make out the magnet dust/epoxy spacer on the magnets.

The crosswise magnet retaining tabs have been hammered flat – to bend them in over the shimmed magnets needs tooling – simply bending will likely crack or chip the magnets. I just place a blob of solder on the inside as a retainer and hope the epoxy does its job.

Above is a diamond-coated magnet hone (forget the thumbscrew unless you want to wear out your fingers, use an electric drill/cordless on slow speed). These are available in different sizes from most US slot car parts suppliers.

You need to specify size – typically 0.550” (which is going to give you about 0.010” clearance over a standard armature.

I do this immersed in water for cooling/lubrication, cooling being more important than lubrication. I used to use a light oil or paraffin – water seems just as good and far less bother.

You obviously assemble this into the can and endbell and slowly use it to bore through the magnets. This gives you a perfectly symmetrical bore.

- Rob Voska likes this

#9

Posted 13 July 2014 - 07:02 AM

Magnets & Magnet Zapping

Magnets are made by sintering various materials into shape (materials such as ferrite, nickel, iron, neodymium, boron, samarium, cobalt, etc.) Sintering consists of first mixing these materials as a very fine powder (consistency of talcum powder) followed by compaction into a die under immense pressure followed by heat treatment in a controlled atmosphere furnace (typically a vacuum or reduction atmosphere) to fuse some or all of the materials together.

At this point the blank has no magnetic field.

The blank is then placed into what is generally termed a “Magnet Zapper”, typically a high permeability magnetic circuit into which the blank is placed. Usually the pole pieces focus down to the blank and the tips conform to the shape of the blank (re: earlier comments about air gaps being bad news to magnetic circuit strength) typically clamping the blank in place with no clearance whatsoever.

Magnet Zappers for slot cars typically consist of a coil and the motor can, magnets, and core blank are placed in the center of the coil.

Below a typical slot car zapper – note plastic holder for the motor can (axle side – North – up).

Can and holder are then loaded into the coil.

On firing the zapper an immense pulse of electrical energy from a capacitor is discharged into windings around this magnetic circuit - briefly introducing a very large magnetic field – this permanently polarises the magnetic blank(s). Zapper above produces 25,000G for 1.5ms which is sufficient to reverse a 1,200G slot car Ceramic-Ferrite magnet pair.

Typically this saturates the blank to its maximum magnetized state. Its maximum magnetic strength therefore depends on the material it was made from in the first place.

Some magnet formulation such as NIB (Neodymium-Iron-Boron) can be zapped to much higher magnetic strengths than say a ceramic-ferrite type – but the ceramic-ferrite type is less susceptible to fade and more resistant to heat than the NIB, so it’s a case of selecting what is suitable for the application.

For slot car motors the ferrite-ceramic is typically used, as the NIB type (although more powerful ) are much more likely to fade in the presence of heat, mechanical shock, and the alternating fields of the armature.

Magnetic Failure in a Slot Car Motor

The motor magnets are subjected to heat in use (as well as heat from soldering into place) and the magnetic influences of the armature whirling away inside of them – this has the tendency to demagnetise the magnets over time.

It also tends to drag the field out of line, displacing and unfocussing it – you may notice the effects of this in a motor that has gone “off the boil” for no obvious reason. You place it on the shelf and two years later in desperate need of a motor you press it back into service to find its now working well again (perhaps not as good as it once was but certainly better than when you shelved it). What has happened is that the magnetic field has realigned itself while sitting idle. (It might realign but it will never regain its strength.) Such a motor would be rejuvenated by zapping its magnets.

Magnet Zapping

Commercially-available magnet zappers are available for remagnetizing slot car magnets. This can generally be done in a number of ways:

1) For the coil type (shown above), the can and magnets (without endbell nd armature) with a core plug between the magnets is placed into a non-magnetic (plastic) holder to secure the assembly in the middle of the coil’s magnetic field. With this type of zapper you do not have the ability to zap a mounted or assembled motor (never a good idea in any case) – but they are way cheaper and more convenient to carry around than a hard pole type (which typically weigh 10-20kg).

The iron slug may be a simple best fit round bar or a dual radius profiled slug (the inner radii do not share a common centre). The best fit round bar leaves air gaps at the outer edges so the magnetic field is focussed towards the centre – which is generally good – but the overall magnetic strength may be reduced due to the outer edges not saturating.

A conformal plug will produce a straight through field which will be stronger overall be but not focussed towards the middle where it will do the most good.

The best fit round bar is in my opinion the best method as its simplicity outweighs any dubious advantage.

Note: The iron “slug” should always be made out of high permeability 4% Silicone-Iron. Mild steel is a poor substitute (but it works fine on ferrite-ceramic types).

2) For the “hard pole” type of zapper, the magnets are placed in the zapper with an iron core dummy rotor to fill the diameter in the inside of the magnet pairs as for the coil type. The clamps may conform to the outer radius and the core to the inner radius – for little or no air gap. See later, the inner slug can be slightly smaller and the clamps flat faced which will “focus” the field towards the centre of the magnet.

With this type of zapper the magnets can be zapped in the can, out of the can, singly, or in pairs or even the whole motor – in some cases even if soldered into the chassis (if access permits).

A "hard pole" type magnet zapper

3) As mentioned above, you can do one magnet at a time (with appropriate pole pieces) – the gain of a slight increace in magnetic pulse (due to a shorter magnetic circuit) does not necessarily result in a more powerful magnet which has almost certainly been saturated (will not get any stronger). Worse, a pair produced in two goes may have field misalignment and focus problems so its safer to do magnets as matched pairs.

4) The next method is to zap the magnets in the motor can, with the armature in place and the brushes removed. If you don’t remove the brushes there is likely to be a large electrical short (of the pulsed induced voltage into the windings) which can damage the commutator and brushes). It will also interfere with the “zap”.

With this method you have the iron can and the air gaps to the rotor to interfere with your magnetic circuit as well as the limited saturation of the armature – so you will probably not achieve saturation of your magnets. Also the three-pole armature can never align properly with the two pole magnets so the resulting field will be somewhat out of shape (see diagram later).

Additionally, the armature will become polarised – but this is not a problem as it is demagnetised in the first few revolutions once it is spun up – by the rapid cycling of the poles.

This method is not recommended other than as an emergency measure – however if it works well, then it works. Feel free to do it again but I don’t approve.

Approximate Magnetic Field Shape Conformal vs Non-Conformal Clamping of Magnets in Zapper

From the above it can be seen that using conformal pole pieces and slugs creates the potential for a far stronger magnetic circuit (by eliminating air gaps).

However using the simple flat faced poles (normally as supplied with the zapper) and a simple iron core tends to focus the magnetic field at the expense of the outer edges being less than fully saturated – this will also happen in a “coil type” zapper as per the photo above. Since the bulk of the armature’s power output (per pole) is at the center and the outer edges only serve to increase underbrush shorts this set up is generally advantageous as well as being simpler.

Clearly there is yet another trade off at work here as to how much focussing is beneficial to the trade off loss of overall magnetic field strength. Equally clearly this can be adjusted by the shape of the clamping and core pieces – your guess is as good as mine!

Note: Zapping a magnet generally restores it to its original desired saturated condition; it will not make the magnet “stronger” as such.

Caution: Magnet zappers should not be used near electronic apparatus, memory storage devices or PERSONS WITH PACEMAKERS or hearing aids. The EMP (electromagnetic pulse) given off when the zapper is fired is potentially hazardous.

Remove your digital watch, cellphone, iPad, magstripe or chip and pin credit cards to a safe distance – typically more than 3m away preferably behind a steel shield.

A final caution – follow the zapper’s instructions as to pole orientation. if you put your magnets in the “wrong” way around their field will be reversed (and the motor will then run the other way). If you do this, correct by rezapping twice the right way around – as one zap may not fully coerce the field reversal – similarly if you elect to keep the accidental reversal you should also zap it a second time for the same reason.

A good zapper should be able to completely reverse the magnetic field with one zap.

Quad Pole (Multipole) Magnets

Multiple poles are used to further increase the “focussing” and alignment of the magnetic field to where it will do the most good.

From the information earlier, an individual pole is going to do most of its work over 60° (±30° from the center of the magnet) so this is where we would like most of the magnetic field to be focussed – since the next 60° gets involved in underbrush and dead shorts we would be quite happy for there to be no field at all here – but unfortunately that is not possible – but it emphasises why we want to “focus” the field toward the centre. The armature, clearance, and radius mismatch all have a role to play here. More on this later.

What should be obvious is that you cannot zap multiple pole pieces without first dismantling them and individually zapping opposing pairs before reassembly (they are usually epoxied together or into place with special epoxy). A PITB!

So these are normally purchased from a manufacturer already built up – often already in a can.

If you zap an assembled multipole you will turn it back into a single (made up of many parts but nonetheless a single).

The radial is achieved using an external conformal pole and a small internal wedge/radius tipped centre pole (as per earlier graphic) – however because of the large non-magnetic (µ0) gap this requires a massive jump in deliverable power not obtainable in most zappers.

The same would be required for zapping assembled multipoles.

You can approximate a radial magnet by using a “butterfly” shaped conformal core slug which is also suitable for multiple poles, as hsown below.

Since your zapper will have limited power we want to get as much out of this as possible – so use high permeability iron, make the non-concentric outer radii to suit (the best fit diameter is less than optimum here but you can do that for expediency).

Next machine the “V” either side – the gap in the middle should be as small as possible – obviously it can’t be zero but 1-2mm would be nice – however your zapper may not be powerful enough to wrangle the zapping flux through this reluctance, so start bigger and work your way down. Generally 3mm will work – you can also have a radius in the bottom of the “V” – then you can machine” this by drilling and hacksawing; crude but effective if you don’t have machine tools.

In the RH drawing the material to be removed is shaded in green. Particularly note the two crescent slivers because of the magnet face radius being bigger than the blank radius – non-coherent centres. Obviously if you have honed out your magnets this does not apply; the magnet inner radii are true to the centerline.

At each step, zap a pair of magnets and then reverse zap – if it reverses from full forward to full field reversal then you are OK and can take off more material but eventually you will run into trouble (you will need a Gaussmeter to check).

If your zapper could not effect a field reversal in the first place then there is something wrong with it – replace or uprate it. Most zappers can be “upped” by simply increasing the value of the capacitor bank (add more capacitors).

Above photo – plain and focussed zapping core plugs – standing on a graph of back to back motor trials which show no significant difference in output power.

However the focussed field was much more sensitive to changes to advance and retard – see advanced motor testing later. I am not entirely sure what to make of this; there is only a small but insignificant advantage to the focussed field on the dyno but spun up off the dyno the motor sounded “wilder”. I suspect the focussed field was less troubled by underbrush shorts but the focussed field narrowed down the timing “sweet spot”.

Also the dyno’s inertial disc is not entirely “load free” and the aerodynamic drag of the photocell holes becomes considerable at high revs and the same unfocussed motor unloaded without the disc spun up to 65,000 RPM (measured with an optical tachometer) whereas it topped out at just over 50,000 RPM on the dyno.

The focussed field motor ran to 67,500 RPM at 12.5v so it was marginally faster unloaded.

So zero torque on the dyno means the disk is no longer accelerating – so it’s missing the torque driving aerodynamic, and brush and bush friction – but overall that would only result in a “stretching out” of the above graphic and therefore does not detract from the fundamental usefulness of the dyno (eee advanced motor testing later).

- Rob Voska likes this

#10

Posted 13 July 2014 - 07:53 AM

Field Shape

The following is the approximate field shape with the armature in place but static and no power on the armature.

What should be apparent is that focussing the field is advantageous but is a smaller advantage than you might think.

The illustration on the left should also explain why zapping a motor with the armature in place (instead of a round blank) will never produce an equal and opposite pair of magnets. It might produce an overall magnetic field which is comparable but the one will be focussed to the middle and the other to the outer edges which is poor for performance and enhances underbrush shorts – so it’s generally a lose-lose situation.

Air Gap

In most slot car motors the gap between the armature and the magnet faces is smaller at the middle – i.e. they are not parallel/on the same center.

This is a “cheap” way to focus the magnetic field but at a terrible price in terms of available field strength lost. That said, remember the motor was originally built for a certain wind and that has been taken into account (one would presume) but it does allow you to get more out of your existing magnets – same cautions on appropriateness of winds.

Magnets - Summary

So we can take existing magnets, shim them, zap, and focus them, hone them and polish them all of which might improve our motor’s power output/performance – but only with an armature suitable for this uprate in magnets.

It is also possible to do all this work and suffer diminished performance, which is a serious bummer.

As a rule of thumb I would suggest that when using a standard armature, even a blueprinted one, then it is not worth doing anything to your magnets other than zapping. However for some of the more serious winds, like the PS700B displayed earlier, I reckon its almost mandatory that you up your magnetic performance. That arm certainly has less than standard number of turns and that generally would require “stronger” magnets..

My final caveat on this subject: remember you can always overdo things.

Gauss Readings

Note: Although still widely used, the term Gauss has been replaced in the SI system with Tesla, where 1G =1x10-4T.

Gauss refers to the strength of the magnetic field produced by a magnet – its magnetic flux density.

Meters are available but you can also jerry-rig using compasses or use the pull off force of a steel ball and fishing scale, etc. (search the net for options).

Below a Go Fast Products “Spin Doctor” Gaussmeter.

As pointed out after zapping a magnet will almost certainly be saturated and therefore at its strongest.

What we are concerned with is are our magnets a matching pair and are they stronger or weaker than what we normally use or are they better or worse after zapping, etc., etc. In other words we only need a comparative value rather than an exact scientific result.

A simple alternate method is to lay an iron rod – same diameter as inside radius of magnet but too heavy to be lifted by the magnet - on a digital weighing scale – zero the scale – attach the magnet to the middle of the bar and slowly pull it off – the scale will go further and further negative – note the reading in grams at which the magnet comes loose and record this force as an indicator of its strength. Since this is absolutely only a comparative value, it is imperative that you keep this iron bar for all future measurements.

Next we should want to keep matched pairs together; two magnets in a motor are almost certainly made from the same batch of mixed powders and were zapped as a pair. The same would not hold true for magnets made years apart.

We might find a range of values and after zapping re-match those that most closely match each other. Pack into containers and label their values.

Now we can try a range from weaker to stronger to see which produce the best results on a given armature. Remember the earlier caution that a given “wind” will perform optimally within a certain strength of field – stronger does not necessarily produce better results.

Power Losses in the Motor

Heat and power loss in the motor comes from four sources:

1) Friction: Mechanical and aerodynamic/cooling air - eliminate where possible, bearings, alignment, reduced commutator brush pressure/friction, reduced magnet clearance, polished armatures/magnets, etc. Refer to earlier comments re: magnet position and field strength.

2) Copper losses: I2R losses to resistance of the windings – can be reduced by using the thickest wire you can get on for the number of required turns. The only other alternative is silver wire.

3) Iron losses: Losses due to hysteresis heating and “eddy current” losses in the iron core. These can only be reduced by using the best permeability 4% silicone Iron and by reducing the lamination thickness. Motors with thinner laminations and short stack lengths will lose less power to this phenomenon. Note: short stack length must still have enough iron core to do the job – with respect to wind and field strength.

4) Under brush short circuits: Unavoidable in three-pole motors but can be reduced by correct brush material, spring setting, and correct alignment of brushes.

Advanced Motor Testing

Ideally you need to adopt a scientific method of recording all your modifications and adjustments. Unfortunately that means you need to also be able to measure the outcome.

“Measure that which is measureable, make measurable that which is not!” - Galileo, a very wise man indeed!

Typically this has meant testing against the clock on the track – the problem with that is it is hugely subjective and if (like me) your driving abilities vary and the difference is small you will not really be able to tell.

I have seen any number of half-arsed attempts at building a slot car dyno - commercial and otherwise (including my own “rolling road” below).

This was an awful lot of effort to build, is a PITB to drag around, and is totally analogue. While it works, it only gives you brief glimpses and no output data. Yeah, you can note down a bunch of readings but being a braked dyno it can convert a motor to smoke real quick.

I now use this:

Fantom Racing Products™/deCo SoftWare™ build a slot car motor dyno that works!

How do I know it works?

It delivers repeatable results – re: data comparison of two runs on same motor days apart.

Results are within ±2% which is way better resolution than I have come across with anything else.

You can print the graphics (above) which have been subject to smoothing algorythms – the raw data view is also available as well as a (raw) data download to the desktop which can be pasted into Excel, etc.

The program does not export graphics – the graphic above was created by using the screenprint key (which places a copy of the screen onto the desktop) and then using a photo viewer/editor – in this case MS Paint – new – paste - select area – crop – save as *.jpeg.

It works by accelerating a known inertial mass (aluminium disk) and monitoring the volts, amps, and acceleration (via photocells and four holes in the disk) then calculates torque, power, and efficiency which it displays alongside the amps in the graphics which can be archived in a built-in database.

You can superimpose graphics to compare the differences from any changes you have made.

I am completely blown away by this elegant piece of kit – not cheap but a lot less than I spent building my own and one helluva lot better.

YouTube videos shwowing the dyno in use (on an R/C motor – it’s original design use).

I’m not sure if this version is still available – there are also some DIY dynos on the web using the same principles.

- Rob Voska likes this

#11

Posted 13 July 2014 - 08:05 AM

I am not sure whether Ken is actually monitoring Slotblog, so questions to him may in fact not be answered.

The thread is now open for posts and comments.

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

#12

Posted 13 July 2014 - 11:47 AM

Big meal. Take some time to digest. Brave soul, this guy. Hat's off.

Thanks, Greg, for sharing it.

So hard a judge they hope never to meet as themselves.