Finished September 2014:

Here's how it all started:

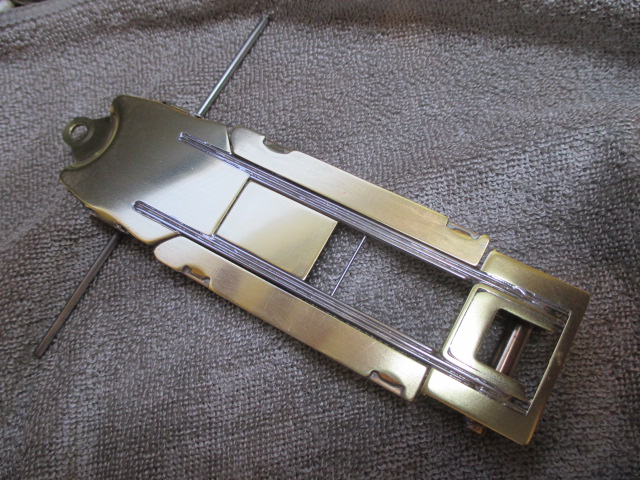

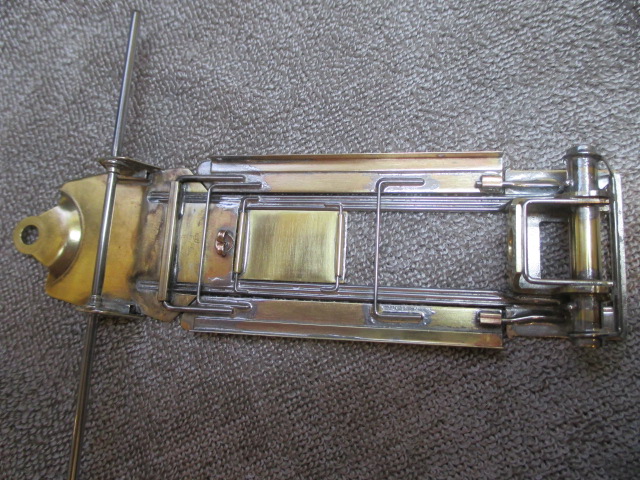

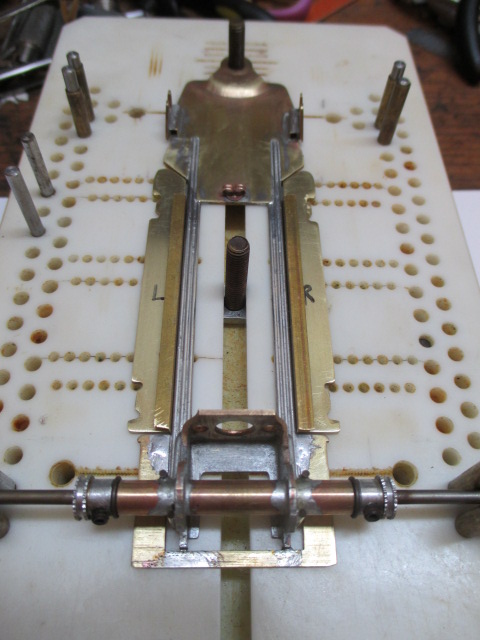

My racing buddy won a Rgeo Victory 2 kit as a race prize and I was chosen to build it ![]()

The first thing I did was grab a Chicagoland McLaren IRRA legal F1 body to use as the planning standard. WB 4", GL 1".

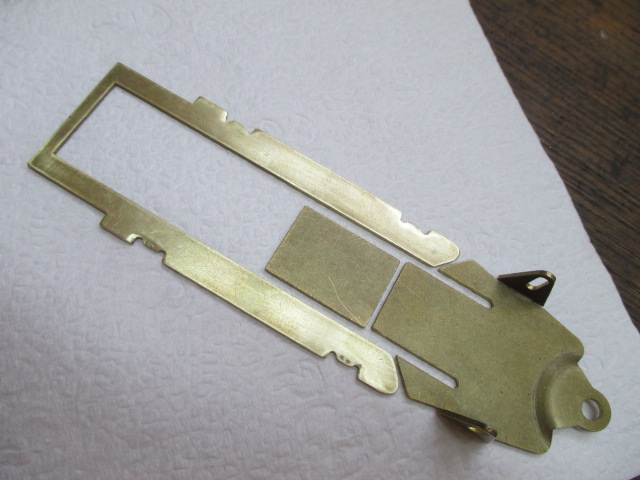

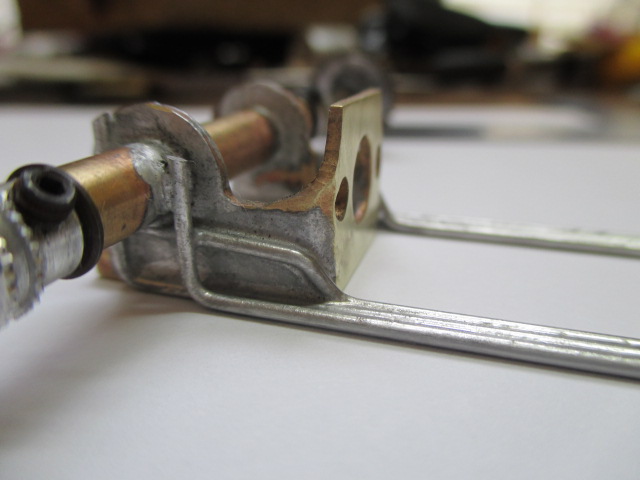

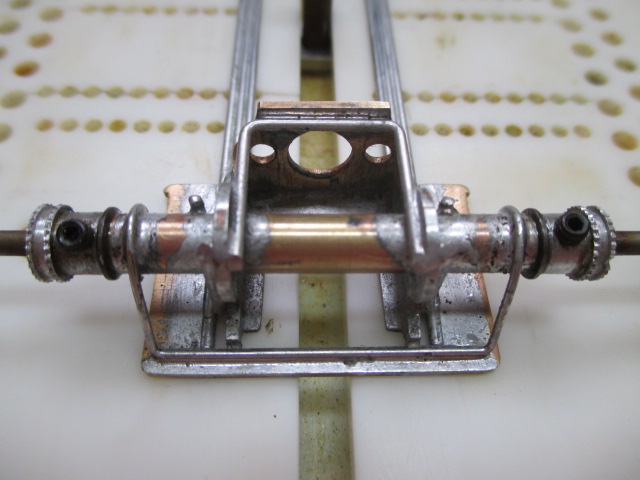

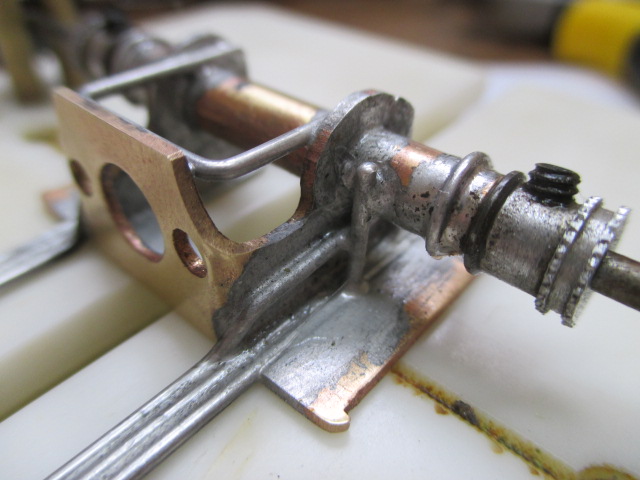

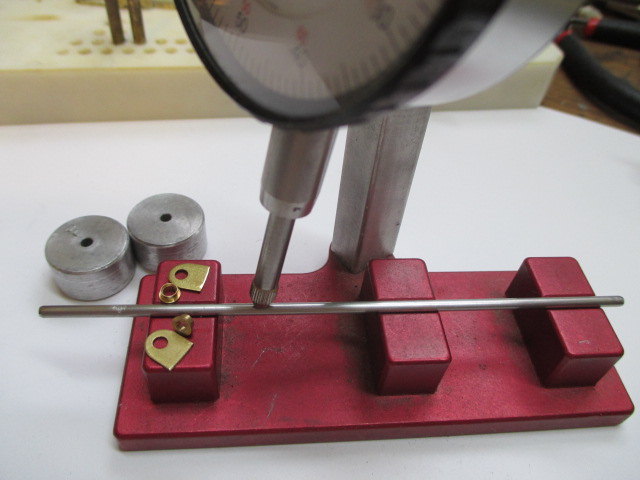

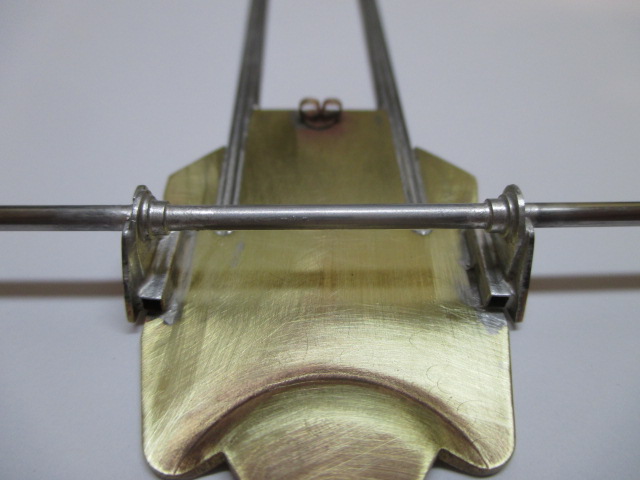

The front axle uprights need to be bent inward and trimmed on top to preclude conflicts with the body. I don't see that as a problem, but I haven't done it yet. The body mount tabs on the pans are very tall and not to my liking so I cut them off and shaved the pans flat where they used to be. I'm going to use 2" JK Indy body clips. Everything else looks like a piece of cake. Kudos to Rick Bennardo, the design is very nice and I'm sure this thing is going to handle great, no matter how badly I screw it up ![]()