For many "experienced" slotters, the Monogram 1/32 kits were our first foray into serious slot cars......an adjustable brass chassis, aluminum screw on wheels, detailed body, tools, decals, and that new fangled "Tiger" x 100 motor....a kid could not be happier..., and once built, it ran away from the Eldons' and Strommies that many of us were thrashing around our basement plastic tracks. As newer/faster motors became available (almost weekly) they were duly installed, and at this point the inherent weakness(s) of the chassis became apparent. It was flimsy, bent far too easily, and would just not handle the power of anything more than the Tiger,.........so a frenzied program of chassis bracing/weighting began.......

This post is to show some of the things we did (and I few I wish we had thought of) to help. For those familiar with building and racing the Mono. chassis', you won't learn much, but, it is always nice to look at pictures.

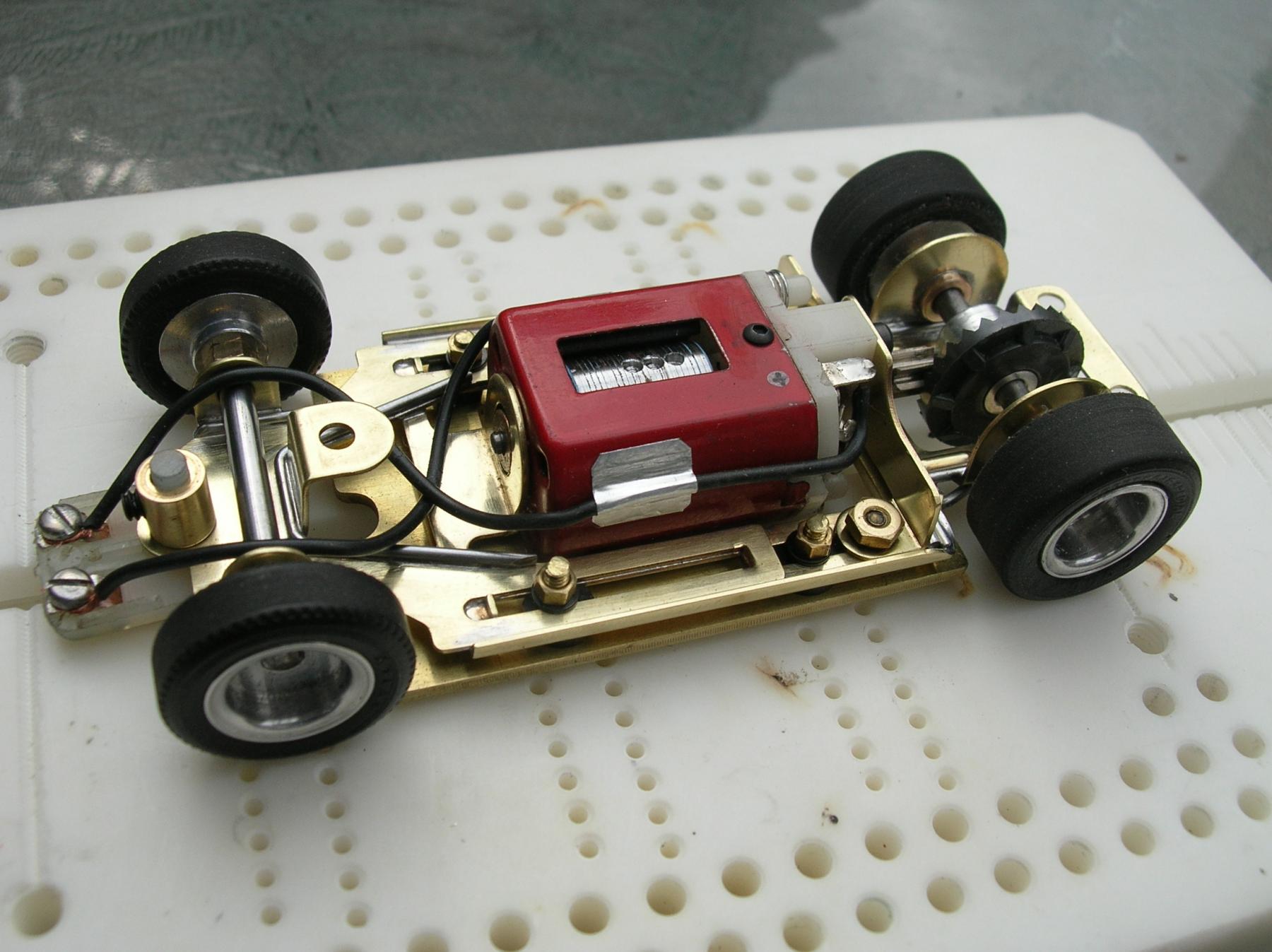

The first pic. shows.....

1/ The chassis halves have been soldered together.....while this makes future wheelbase adjustment a pain, it certainly strengthens the chassis and , you won't have those little screws/nuts coming loose.

2/ The original Mono. rear bushings (even new) had a fair bit of play, and have been replaced with 1/8 x 1/4 oilites. The originals had a proprietary OD, so the rear bushings holes need to be reamed a bit.

3/ Braces have been added, .055 wire for the rear "L" shapes, and the front "C" shape, and .047 for the front uprights.

The 2nd pic. shows....

The front upright brace "L" shapes....by leaving the legs to extend below the chassis, they act as guide stops......(I lost a of lead wires as a kid when the car spun 180 degrees). Leave these a little long until you install the guide....then trim.

The 3rd pic. shows....

An .055 wire brace added to the motor mount.......this must be attached on the side opposite the screw lugs.

The 4th pic,............is of the .055 wires acting as longitudinal chassis braces......the chassis' major issue

The 5th pic............is a .063 brass plate that will be mounted under the chassis using machine screws/nuts.

The final pics, are of the finished chassis, sporting one of Mr. Havliceks' "breathed on" Tiger x 100's......if I had had this car as a kid,..... I would have been the champ!

Cheers

Chris Walker